Method for preparing explosive/aluminum powder core-shell structure spherical composite based on pickering emulsion method

A core-shell structure and composite technology, applied in the field of material composites, can solve problems such as the problem of uniform mixing, and achieve the effect of increasing safety performance and reducing sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

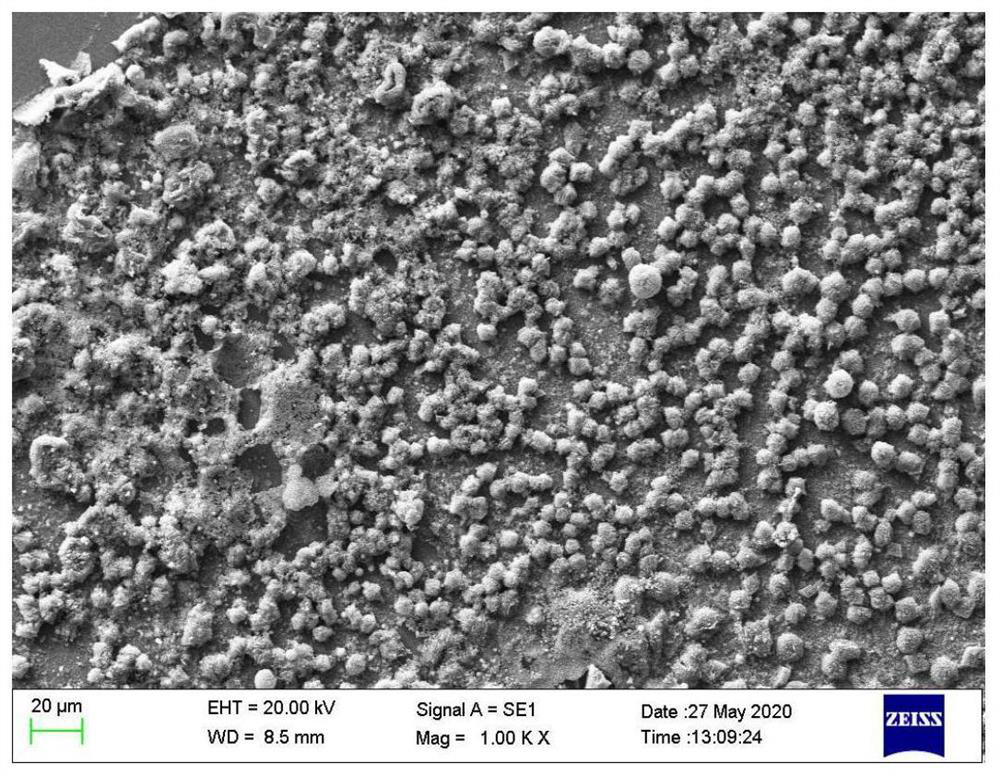

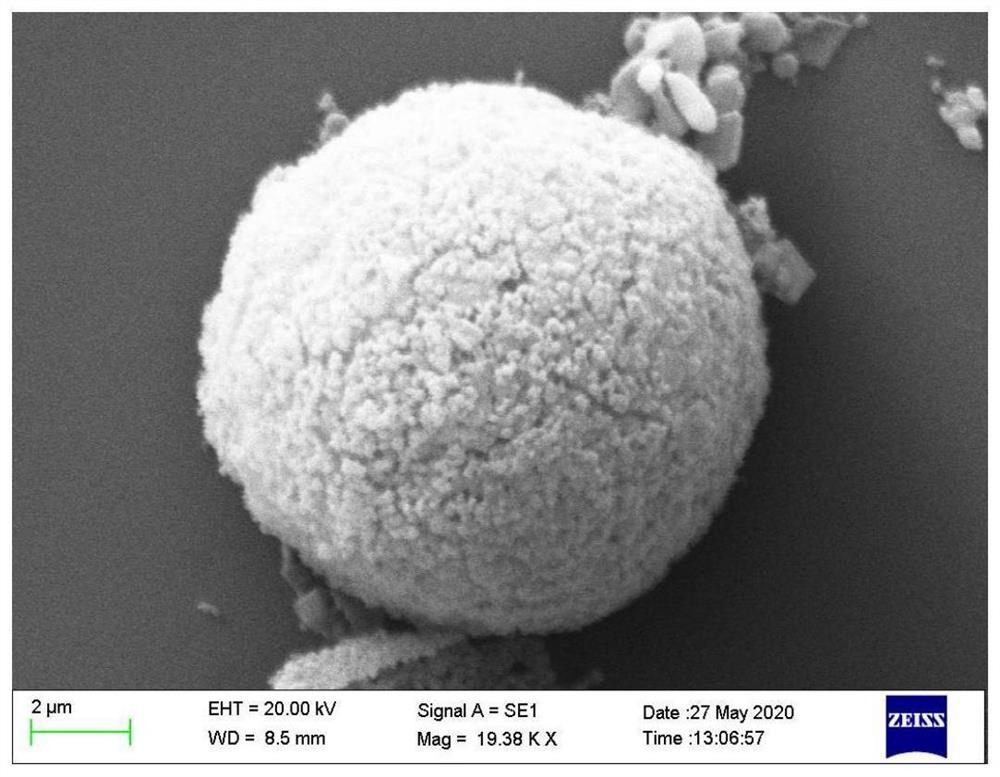

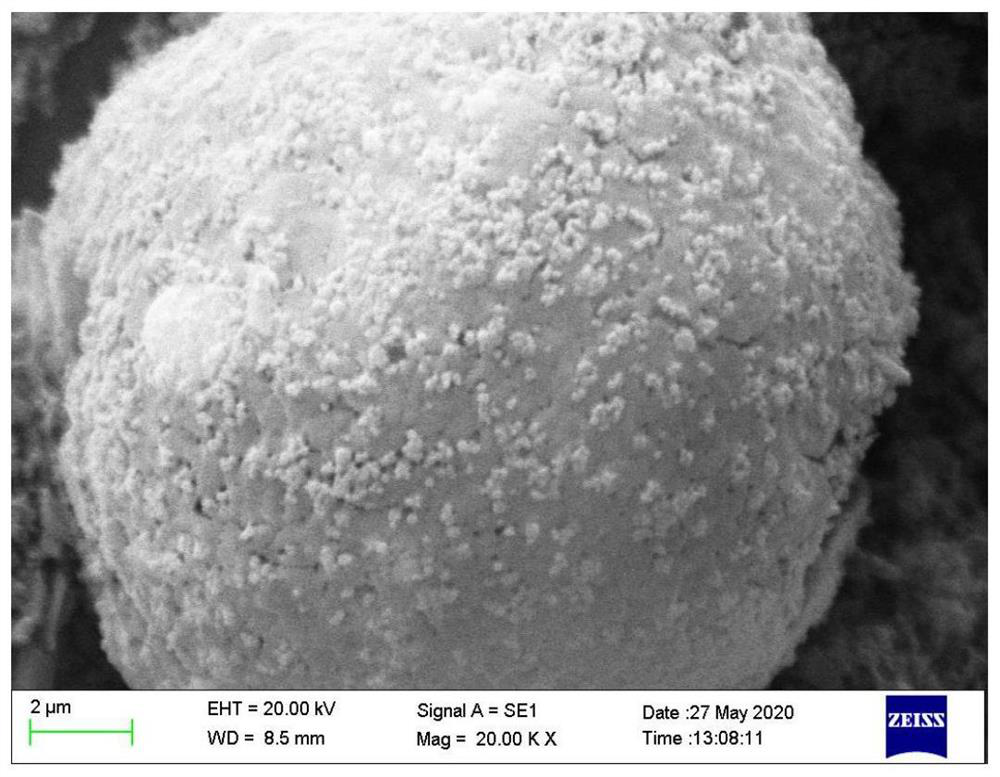

[0028] A method for preparing explosives / Al powder core-shell structure spherical composite based on pickering emulsion method, comprising the following steps:

[0029] Step 1: Add 10g of nano-Al powder into 100mL of ethanol, ultrasonically disperse, add 0.1g of polyvinyl alcohol, slowly add 200mL of cyclohexane dropwise while stirring, centrifuge and dry after 30 minutes of reaction to obtain polyvinyl alcohol-modified nano Al powder, the HLB value is 13.8; the speed of dripping cyclohexane is 2mL / min; the power of ultrasonic is 300W, and the frequency is 45kHz; the speed of the stirring is 150r / min;

[0030] Step 2. Dissolve 2g of CL-20 in 10mL of ethyl acetate, then add 0.2g of polyvinyl alcohol-modified nano-Al powder, add 50mL of distilled water after 10 minutes, and emulsify mechanically for 5 minutes to obtain an emulsion; then add 300mL of it dropwise to the system Distilled water, filtered and dried to obtain Al / CL-20 spherical composite; the stirring speed of the mec...

Embodiment 2

[0033] A method for preparing explosives / Al powder core-shell structure spherical composite based on pickering emulsion method, comprising the following steps:

[0034] Step 1. Add 10g of nano-Al powder to 120mL of ethanol, ultrasonically disperse, add 0.1g of polyvinyl alcohol, slowly add 200mL of cyclohexane dropwise while stirring, centrifuge and dry after 30 minutes of reaction to obtain polyvinyl alcohol-modified nano Al powder; the HLB value is 13.6; the speed of dripping cyclohexane is 5mL / min; the power of ultrasonic is 300W, and the frequency is 60kHz; the speed of stirring is 300r / min;

[0035] Step 2. Dissolve 2g of CL-20 in 10mL of ethyl acetate, then add 0.3g of polyvinyl alcohol-modified nano-Al powder, add 50mL of distilled water after 10 minutes, and mechanically emulsify for 5 minutes to obtain an emulsion; then add 300mL of it dropwise to the system Distilled water, filtered and dried to obtain Al / CL-20 spherical composite; the stirring speed of the mechanica...

Embodiment 3

[0038] A method for preparing explosives / Al powder core-shell structure spherical composite based on pickering emulsion method, comprising the following steps:

[0039] Step 1. Add 10g of nano-Al powder to 120mL of ethanol, ultrasonically disperse, add 0.1g of polyvinyl alcohol, slowly add 200mL of cyclohexane dropwise while stirring, centrifuge and dry after 30 minutes of reaction to obtain polyvinyl alcohol-modified nano Al powder, the HLB value is 13.7; the speed of dripping cyclohexane is 5mL / min; the power of ultrasonic is 300W, and the frequency is 60kHz; the speed of the stirring is 300r / min;

[0040] Step 2. Dissolve 2 g of CL-20 and 2,4,6-trinitrotoluene with a mass ratio of 1:1 in 10 mL of ethyl acetate, then add 0.3 g of polyvinyl alcohol-modified nano-Al powder, and after 10 min Add 50mL of distilled water and perform mechanical emulsification for 5 minutes to obtain an emulsion; then add 300mL of distilled water dropwise to the system, filter and dry to obtain an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| heat release | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com