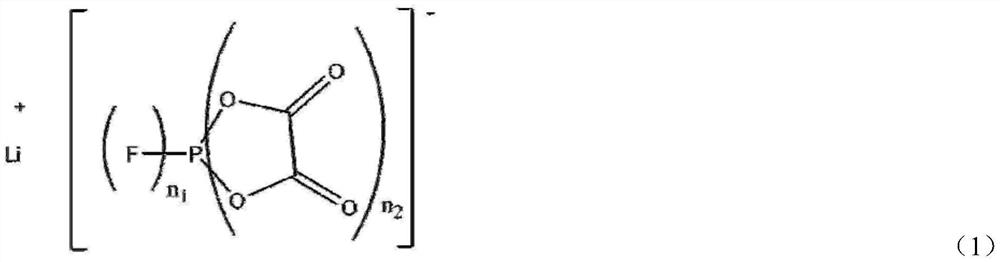

Synthetic method of oxalate lithium phosphate salt compound

A salt compound, lithium phosphate technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as adverse effects on the performance of non-aqueous electrolyte batteries and difficulty in industrialization, Achieve the effects of low cost, high reaction yield and simple reaction operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

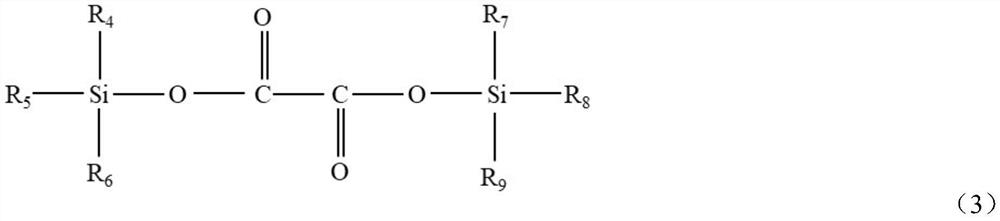

Embodiment 1

[0038] Add 0.124mol ammonium hexafluorophosphate, 0.254mol bistrimethylsilyl oxalate, 0.150mol lithium hydride and anhydrous diethyl carbonate to a 500ml round bottom flask in a glove box, and react at 80°C for 24h until Gas is no longer produced. The solvent was then removed to obtain a white solid with a yield of 94%. NMR test results show that the ratio of LiDFBOP:LiTFOP is 72:1, and the molar percentage of LiDFBOP is 98.6%.

Embodiment 2

[0040] Add 0.124mol ammonium hexafluorophosphate, anhydrous diethyl carbonate, and 0.273mol bistrimethylsilyl oxalate to a 500ml round bottom flask in a glove box, and react at 100°C for 1h until no gas is produced . Then add 0.118mol lithium hydride to continue the reaction, and react at 100°C for 1h. The solvent was then removed to give a white solid with a yield of 89%. NMR test results show that the ratio of LiDFBOP:LiTFOP is 20:1, and the molar percentage of LiDFBOP is 95.2%.

Embodiment 3

[0042] Same as Example 2, except that the addition amounts of ammonium hexafluorophosphate and bistrimethylsilyl oxalate are 0.124mol and 0.254mol respectively, and the product yield is 88%. The NMR test results show that the ratio of LiDFBOP:LiTFOP is 72:1, the molar percentage of LiDFBOP is 98.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com