Waste heat recycling device

A waste heat recovery device and technology for waste heat recovery, applied in seat heating/ventilation devices, internal combustion piston engines, engine components, etc., can solve problems such as ineffective recycling, inability to realize diesel engine waste heat, and increased starting torque of diesel engines , to achieve the effects of low production cost, improvement of difficult working environment and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

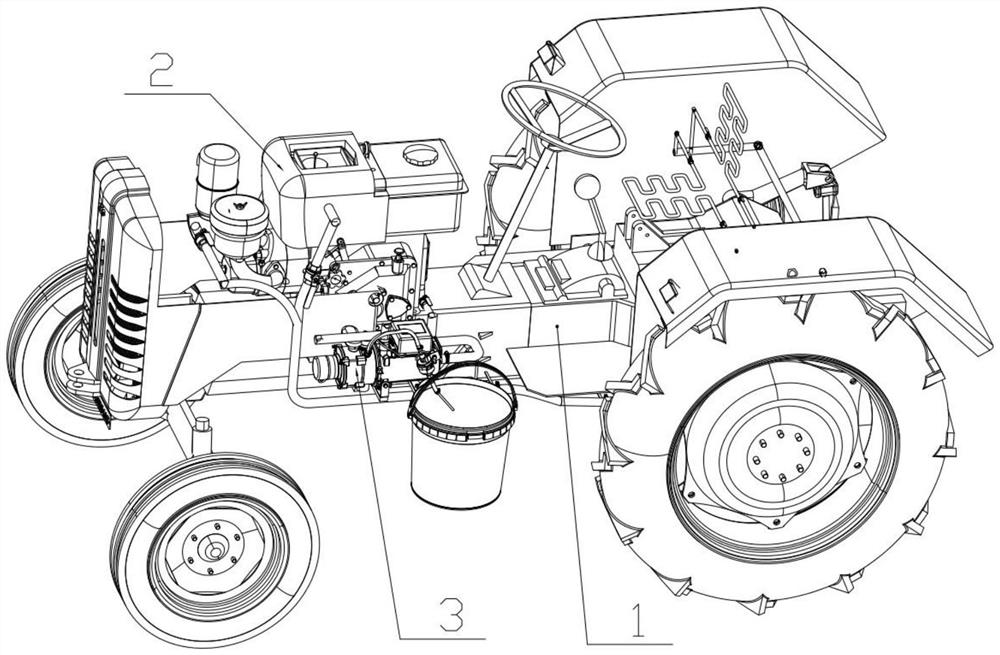

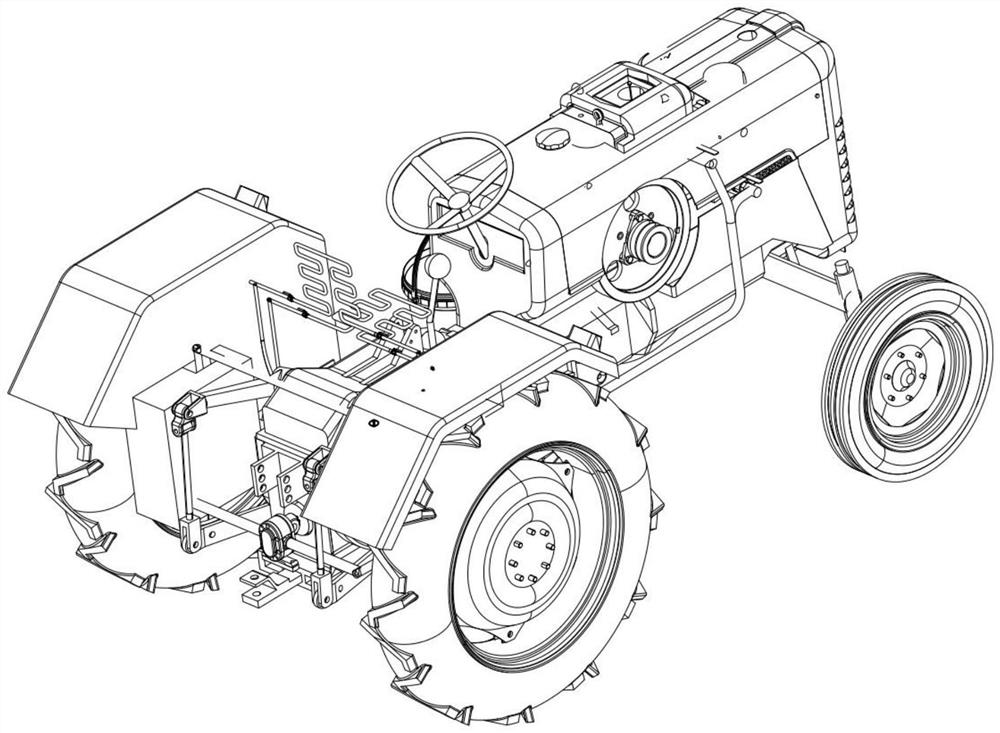

[0033] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 Shown is a waste heat recovery device. Tractor 1, waste heat recovery device 2, waste heat device 3.

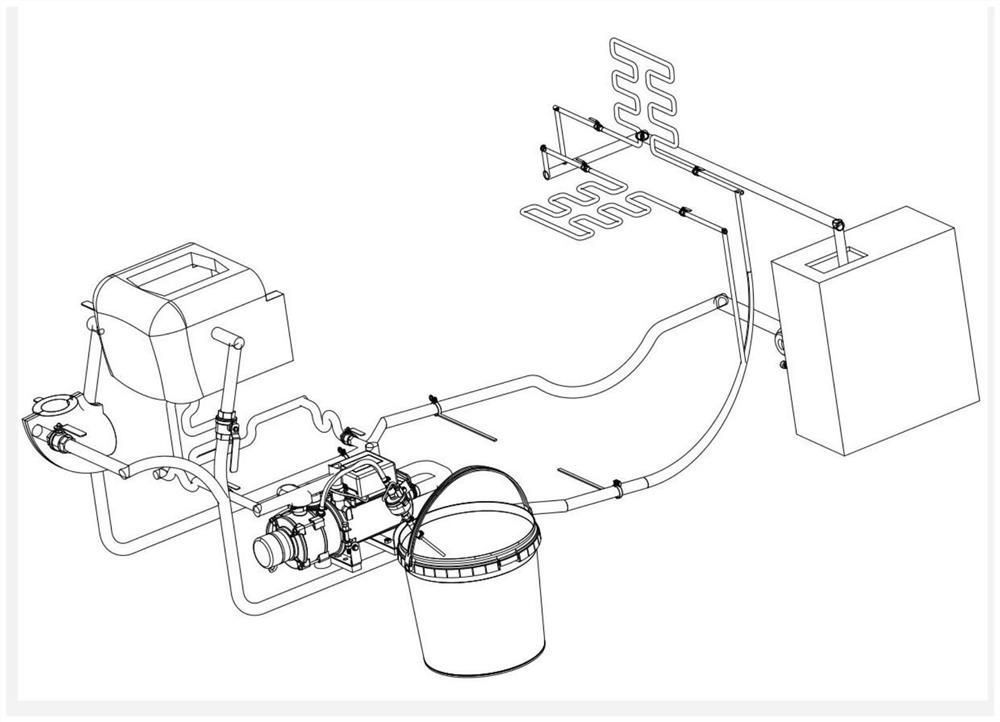

[0034] The specific structure of the waste heat recovery device 2 is as follows: Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the water pump inlet pipe 201 and the water tank 226 are fixedly installed, the water pump water inlet pipe 201 is fixedly installed on the gear pump 202, the gear pump 202 and the rear transmission shaft of the tractor are installed in rotation, the water pump outlet pipe 203 and the gear pump 202 are fixedly installed, and the water pump outlet The water pipe 203 and the main shaft lower bend 204 are fixedly installed, the main shaft lower bend 204 and the front pipe clamp 205 of the water inlet pipe are fixedly installed, the front pipe clamp 205 of the water inlet pipe and the front pipe c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com