Melting channel type cored induction zinc sheet casting furnace for zinc ingot production line

A technology of production line and melting casting furnace, which is applied in the field of melting channel type cored induction zinc flake melting and casting furnace, which can solve the problems of short service life of the furnace body, low zinc melting rate, high energy consumption of molten zinc, etc., and improve the ability of anti-leakage , reduce the temperature of the furnace shell and optimize the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

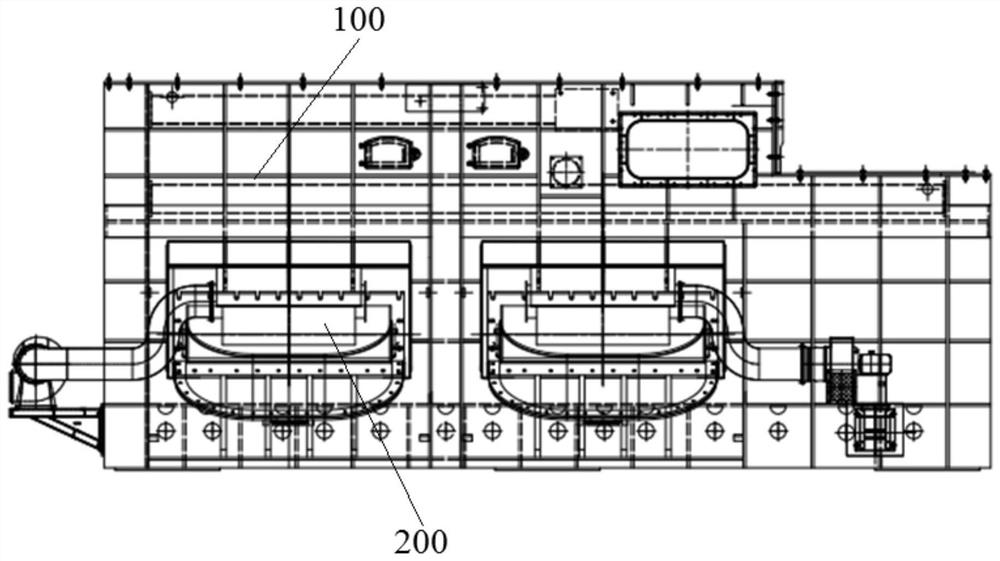

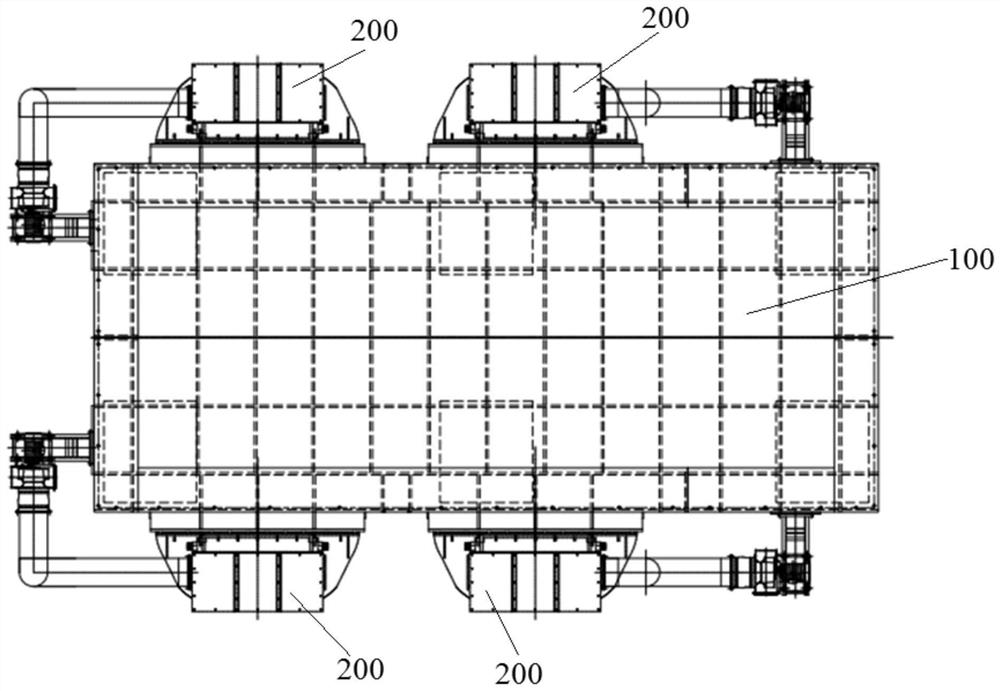

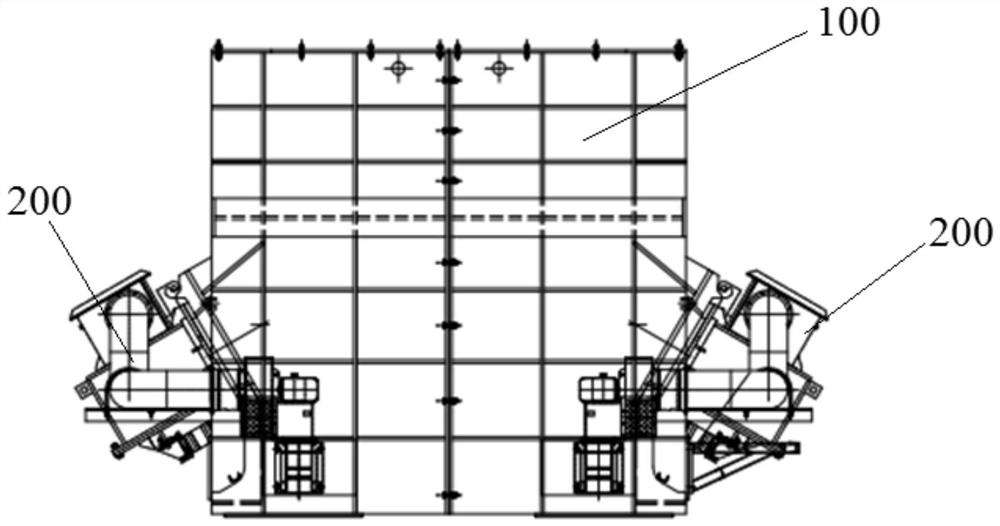

[0021] see figure 1 , figure 2 , image 3 and Figure 4 , the best embodiment of the present invention, a melting channel type cored induction zinc flake melting and casting furnace used on a zinc ingot production line, includes a furnace body 100 and several inductors 200 arranged outside the furnace body 100 .

[0022] The furnace body 100 includes a furnace shell 1 and a furnace wall refractory material. The furnace shell 1 is a rectangular parallelepiped structure made of thick steel plates processed and welded. . The shape of the furnace shell 1 is a cuboid, the upper part of the furnace shell 1 is open, and the surrounding and bottom surfaces of the furnace shell 1 are respectively welded with reinforcing ribs. The furnace shell 1 is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com