Improved denitrification method of SBR

A denitrification and reactor technology, applied in chemical instruments and methods, sustainable biological treatment, water pollutants, etc., can solve the problems of long start-up time, strict environmental requirements, and low proliferation rate of the reactor, and save energy. , good denitrification performance, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

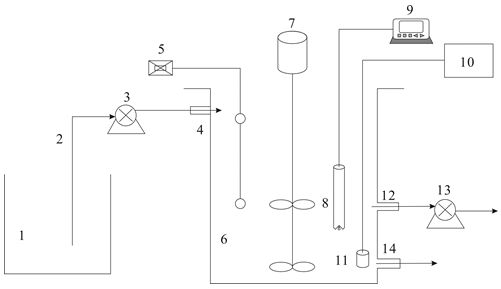

[0013] In order to make the above objects, features and advantages of the present invention more clearly understood, the present invention will be further described below with reference to the accompanying drawings.

[0014] like figure 1 As shown, an SBR coupled anammox process device is provided, including a water inlet bucket 1 and an SBR reactor 6 . The influent water is first subjected to deoxygenation treatment to control the dissolved oxygen in the influent water to be less than 0.2 mg / L, and then transported to the water inlet 4 by the influent pump 3 through the water inlet pipe 2 . The size of the SBR reactor 6 is 20 cm×10 cm×50 cm and the volume is 10 L, which includes a liquid level controller 5 , a stirrer 7 , a pH probe 8 , a pH online adjustment monitor 9 , a blower 10 and an aeration sand head 11 . After the inlet water and the microorganisms in the SBR reactor 6 are fully mixed and reacted, it is left to settle and the effluent water is pumped out of the SBR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com