Preparation method for Bi2O2CO3-Bi2WO6 composite photocatalyst

A catalyst and composite light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of cumbersome steps, high energy consumption and unfavorable industrial production, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

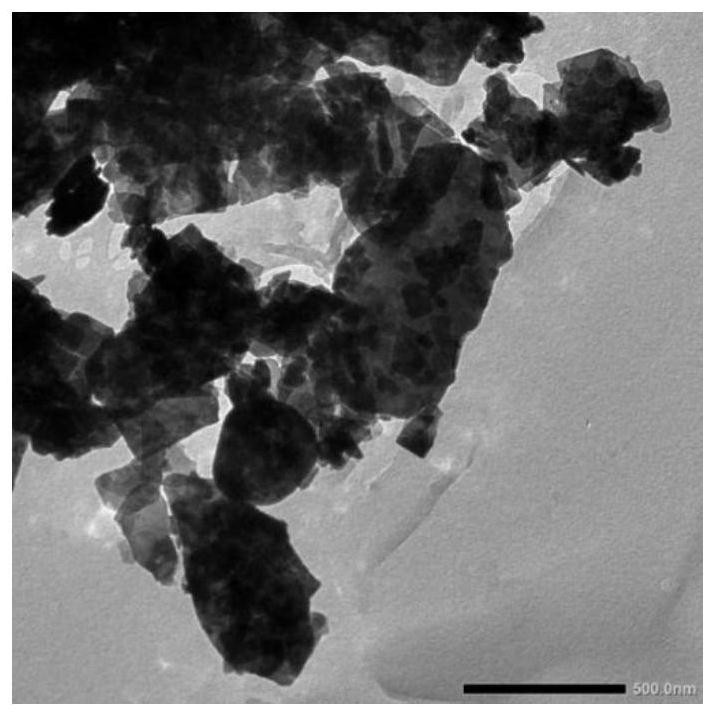

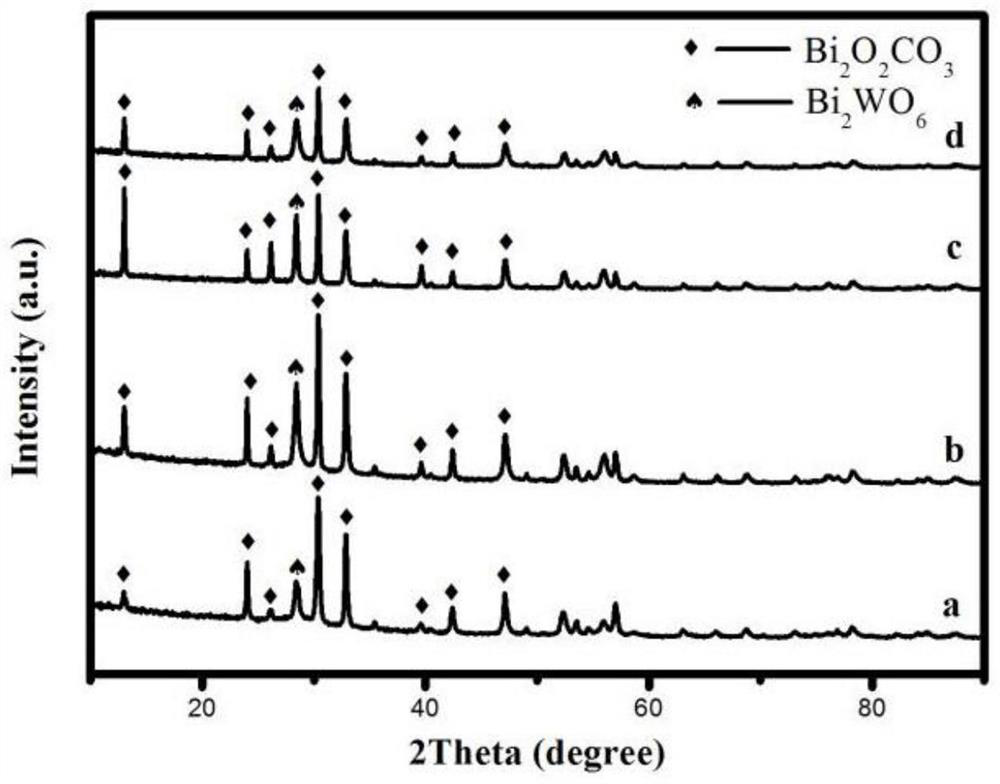

[0019] Specific embodiment 1 (molar ratio 10:1, figure 2 a)

[0020] Take 2.425g Bi(NO3)3 5H2O and 0.165g Na2WO4 2H2O and add them to 30 ml of methanol solution, mechanically stir for 1 hour, then transfer to an autoclave with a pressure of 4Mpa; place the autoclave in a constant temperature drying oven, React at 200°C for 6 hours; after the reaction kettle is naturally cooled to room temperature, the product is filtered, washed, and dried to obtain a Bi2O2O3-Bi2WO6 composite photocatalyst.

specific Embodiment 2

[0021] Specific embodiment 2 (molar ratio 5: 1, figure 2 b)

[0022] Take 2.425g Bi(NO3)3 5H2O and 0.33g Na2WO4 2H2O and add them to 30 ml of methanol solution, mechanically stir for 1 hour and then transfer them to an autoclave with a pressure of 4Mpa; place the autoclave in a constant temperature drying oven, React at 200°C for 6 hours; after the reaction kettle is naturally cooled to room temperature, the product is filtered, washed, and dried to obtain a Bi2O2O3-Bi2WO6 composite photocatalyst.

specific Embodiment 3

[0023] Specific embodiment 3 (molar ratio 5:3, figure 2 c)

[0024] Add 2.425g Bi(NO3)3·5H2O and 0.99g Na2WO4·2H2O into 30 ml of methanol solution, mechanically stir for 1 hour, then transfer to an autoclave with a pressure of 4 Mpa; place the autoclave in a constant temperature drying oven , and reacted at 200°C for 6 h; after the reactor was naturally cooled to room temperature, the product was filtered, washed, and dried to obtain a Bi2O2O3-Bi2WO6 composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com