Axial bolt type camshaft automatic positioning device and using method thereof

A technology of automatic positioning and camshaft, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems of high production cost, weakening of camshaft fatigue resistance, complex structure of grinding chuck, etc., achieve low processing cost and reduce labor force Effect of labor intensity, improvement of processing quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

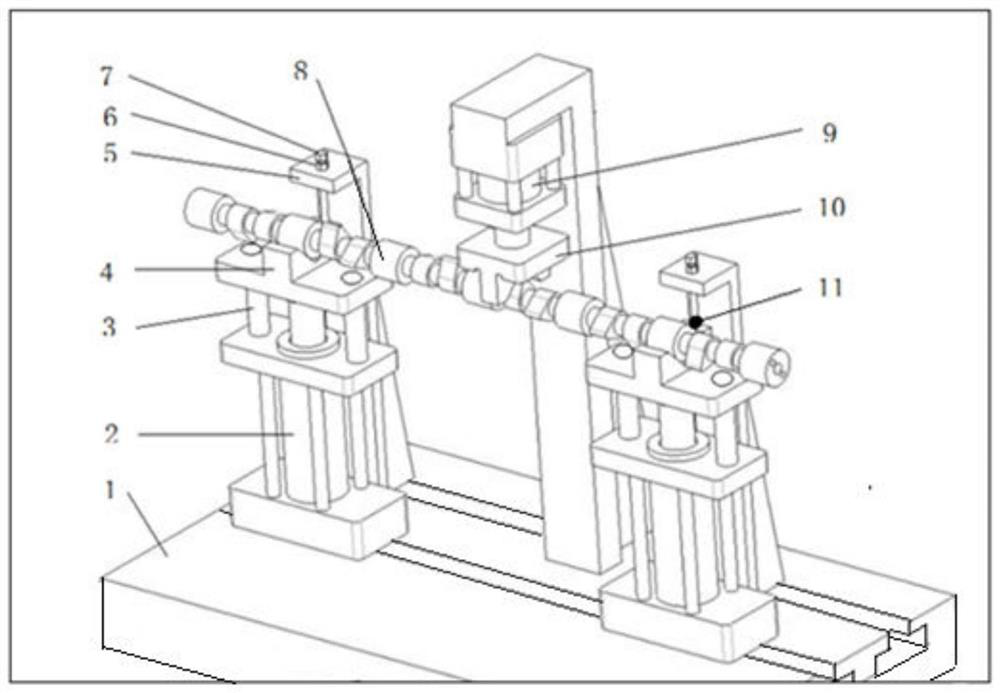

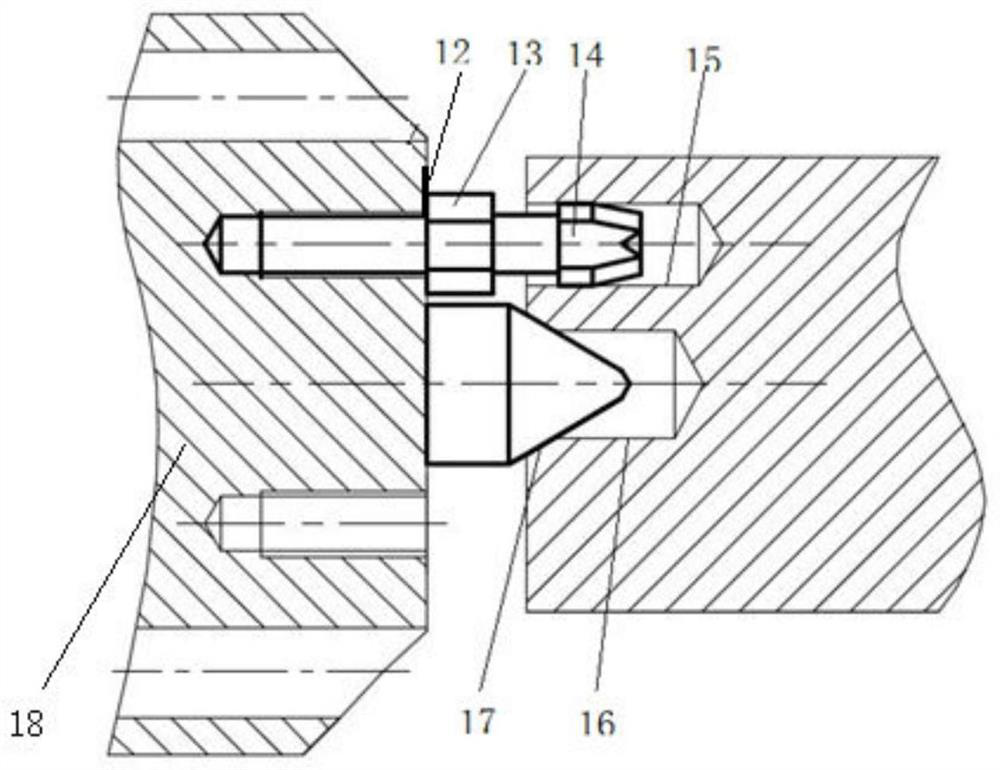

[0035] Take a certain model of 13L automobile engine camshaft as an example. The camshaft is designed with 7 journals and a shaft diameter of Φ40mm, with a length of 1050mm and a weight of 15kg. The left and right end faces are respectively machined with center holes (such as figure 2 , image 3 ), and a positioning hole with a diameter of 10 mm is processed on the left end of the workpiece.

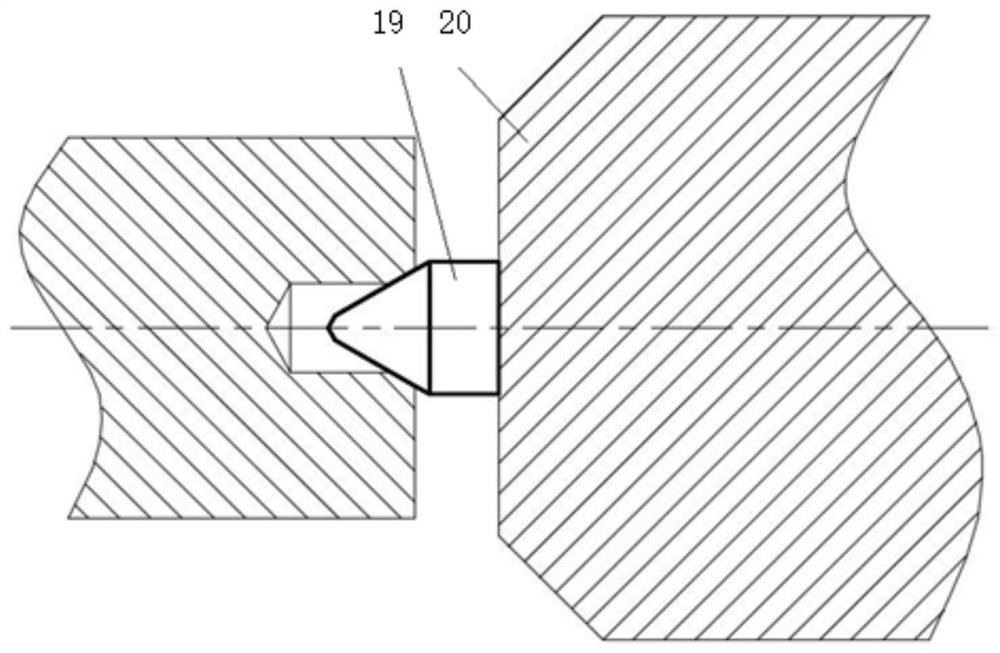

[0036] The device is composed of an end face positioning part, an auxiliary positioning part and a base; the end face positioning part includes a marking line 12, a lock nut 13, a chamfering pin 14, a left top structure (top 17, a top seat 18), a right top structure ( Top 19, top seat 20). The left and right tops (17, 19) limit the 5 degrees of freedom of the workpiece. The use of threaded chamfering pins 14 to replace traditional cylindrical pins can prevent over-positioning and can be reliably connected with the center seat 18. The marking line 12 on the top seat 18 and the trimm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com