Impregnation treatment method for formaldehyde-free flexible impregnated veneer

A technology of impregnation treatment and aldehyde flexibility, which is applied in the field of impregnation treatment of aldehyde-free flexible impregnated veneer, can solve the problems of damage to veneer decorative veneer materials, difficult traces of single-sided tape paper, and increased operation difficulty, so as to achieve easy operation and improved appearance. quality, the effect of eliminating stitching gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

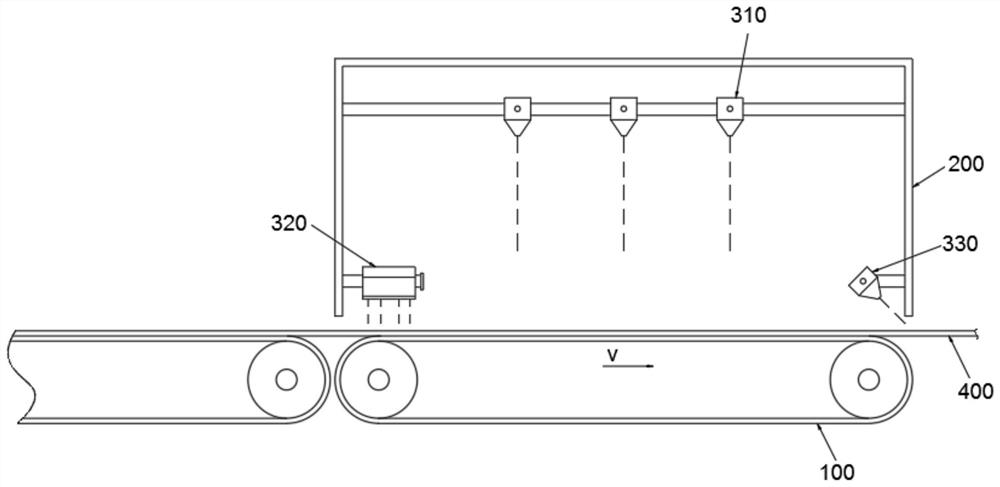

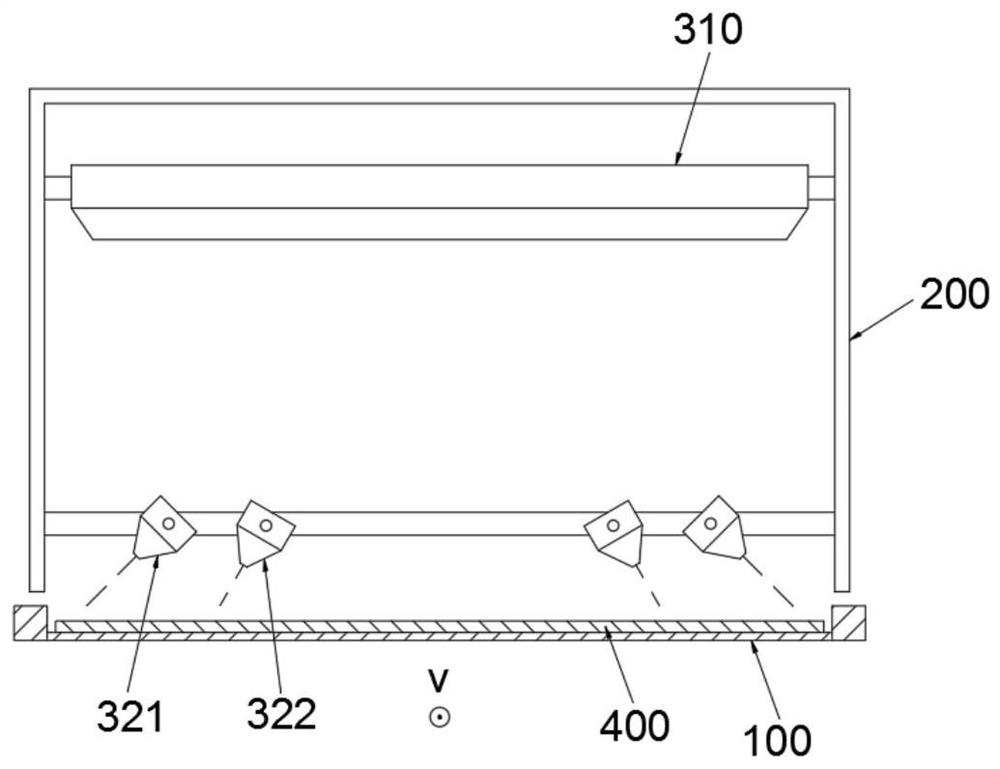

Image

Examples

Embodiment 1

[0038] Example 1: An impregnation treatment method for formaldehyde-free flexible impregnated veneers, which sequentially includes the steps of veneer softening, surface roughening, lengthening and widening, impregnation treatment, and cold pressing for shaping , the step of drying treatment, the step of winding. The specification of the processing veneer is 900mm (length) × 200mm (width) × 0.4mm (thickness).

[0039] 1. The veneer softening step is to immerse the veneer in a softener. The softener used can be any one in the prior art, such as polyvinyl alcohol, glacial acetic acid, penetrating agent, deionized water, etc. Wood softener; the softening process adopted can be any process in the prior art, such as soaking the veneer to be softened in the softener at normal temperature and pressure for 4 to 5 hours, or at 50 to 60 Soak in a softener for 1-3 hours at ℃ and normal pressure; dry the softened veneer until the moisture content is lower than 20%.

[0040] 2. The step ...

Embodiment 2

[0046] Embodiment 2: the difference between embodiment 2 and embodiment 1 is:

[0047] In the step of softening the veneer, the veneer after the softening treatment is not dried, but directly enters the step of surface roughening treatment.

[0048] In the step of surface roughening treatment, the veneer after moisture content drying is sequentially passed through one 0.5mm Dupont wire drawing, one 1.0mm Dupont wire drawing and two 0.3mm steel wire drawing to form a fiber layer on the surface of the veneer , The fiber filament length of the fiber filament layer is 2.0-2.2mm.

[0049] In the steps of joining lengths and joining widths, the length loss at joining lengths is 0 mm, and the width loss at joining widths is 0 mm. That is, in this embodiment, materials are overlapped at non-joining lengths and joining widths.

[0050] In the step of dipping treatment, the veneer is dipped in any water-based acrylic resin in the prior art under normal temperature and normal pressure c...

Embodiment 3

[0051] Embodiment 3: the difference between embodiment 3 and embodiment 1 is:

[0052] The specification of the processing veneer is 900mm (length) × 200mm (width) × 0.6mm (thickness).

[0053] In the step of veneer softening, the softened veneer is dried to a moisture content of 25-50%, specifically, the softened veneer is dried to a moisture content of 30±2%.

[0054] In the step of connecting length and combining width, the length loss at the connecting length is 0-8mm (specifically 2mm), and the width loss at the jointing width is 0-4mm (specifically 1mm); in this step, two adjacent The joint lengths of the boards overlap by 1 mm, so the length loss at the joint length is 2 mm, and the joint widths of two adjacent boards overlap by 0.5 mm, so the width loss at the joint width is 1 mm.

[0055] In the step of surface roughening treatment, the veneer after moisture content drying is sequentially passed through one 0.5mm Dupont wire drawing, one 1.0mm Dupont wire drawing and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com