Packaging box flattening device

A packaging box and equipment technology, applied in the field of packaging box flattening equipment, can solve the problems of affecting work efficiency, slow flattening speed, and easy wrinkling of the cloth covering layer, and achieve the effect of improving work efficiency and flattening speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

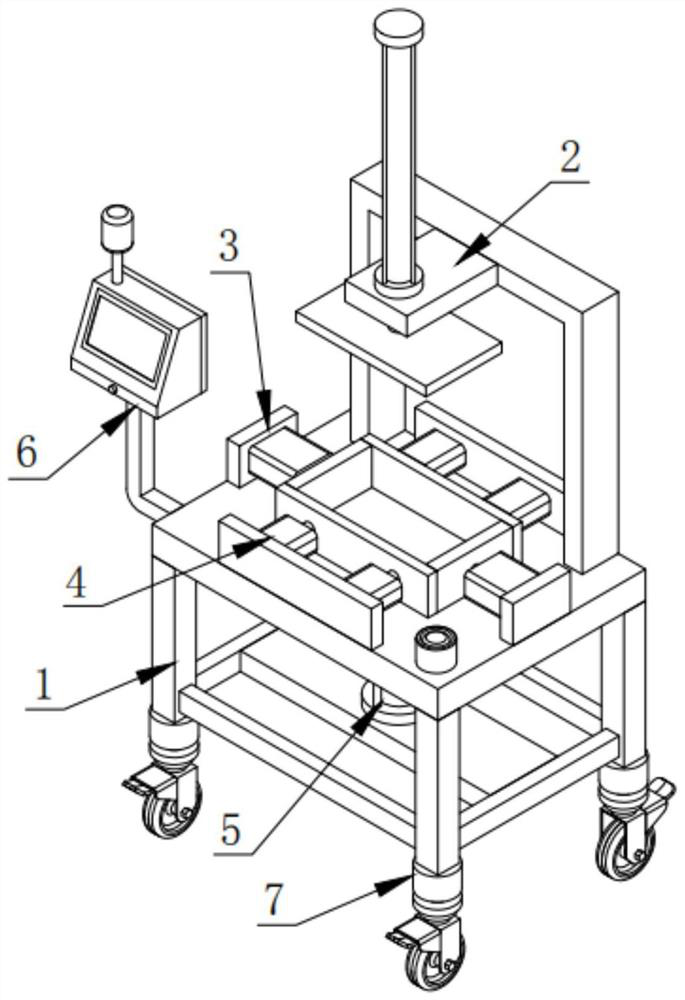

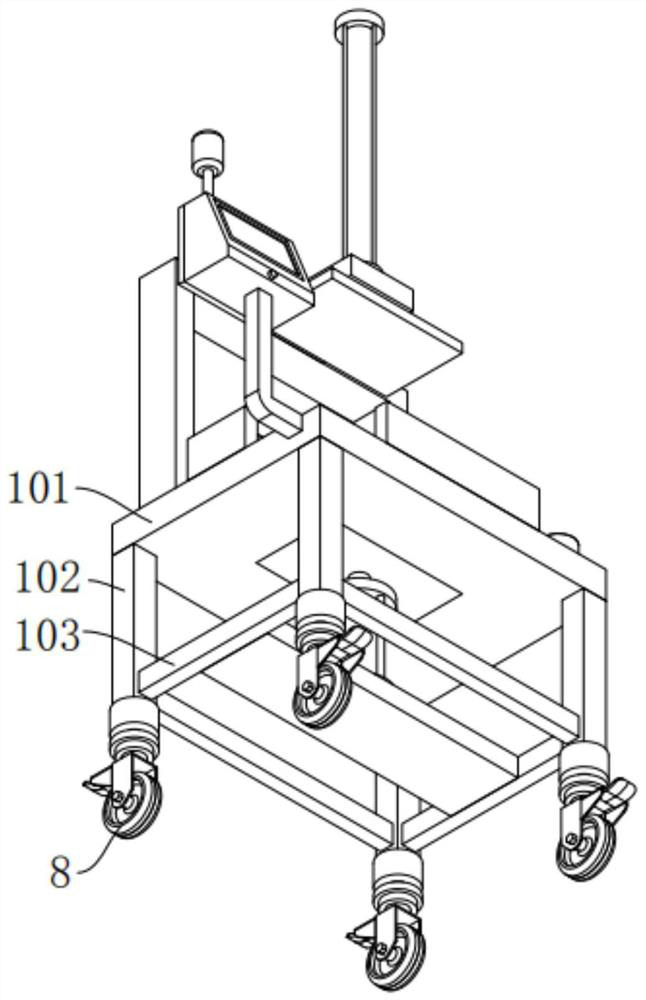

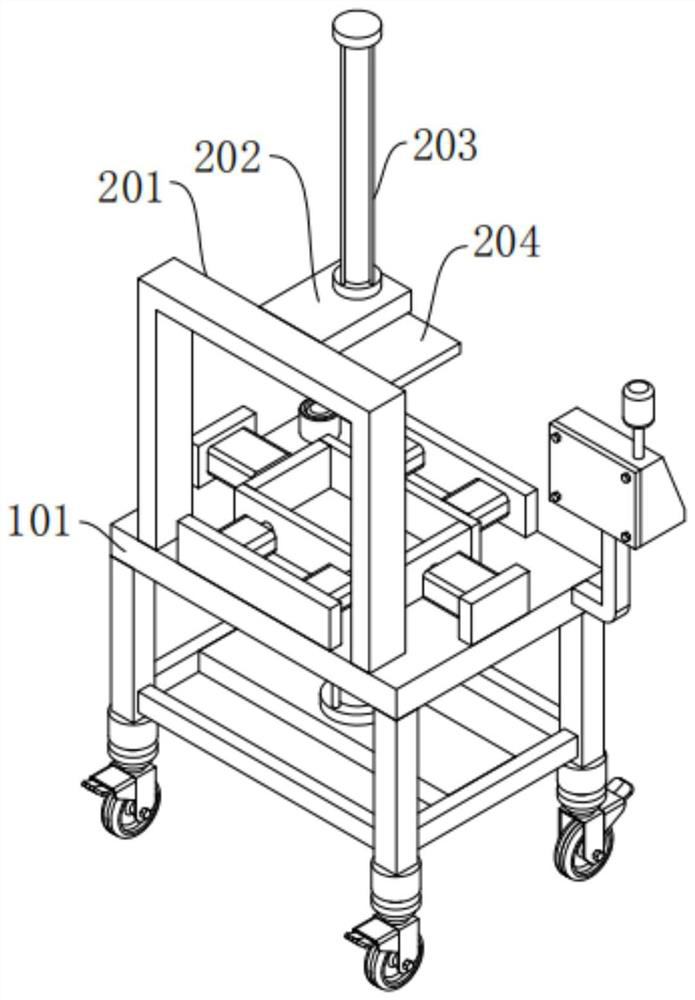

[0043] A packaging box flattening device, such as figure 1 As shown, it includes a frame 1, a group of top surface flattening mechanisms 2, two groups of end surface flattening mechanisms 3, two groups of side surface flattening mechanisms 4 and a group of bottom surface flattening mechanisms 5, the top surface flattening mechanisms 2, The two groups of end face flattening mechanisms 3 and the two groups of side flattening mechanisms 4 are installed on the top of the frame 1, the two groups of end face flattening mechanisms 3 are arranged symmetrically, and the two groups of side flattening mechanisms 4 are arranged symmetrically, the bottom surface flattening mechanism 5 is installed inside the frame 1, the top surface flattening mechanism 2, two groups of end surface flattening mechanisms 3, two groups of side surface flattening mechanisms 4 and The bottom surface flattening mechanisms 5 are arranged in cooperation with each other. In the above technical solution, the frame...

Embodiment 2

[0055] The difference from Example 1 is that the surface of the support plate 101 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0056] Take the following raw materials and weigh them by weight: 13-19 parts of epoxy resin, 5-8 parts of calcium carbonate powder, 10-12 parts of aluminum oxide powder, 12-16 parts of phenolic resin, 8-10 parts of quartz powder, mica 8-10 parts of powder, 3-5 parts of paraffin, 2-4 parts of alcohol ester dodecane, 2-4 parts of triethanolamine, 1-3 parts of emulsified silicone oil and 30-40 parts of water;

[0057] S1. Add the weighed paraffin, alcohol ester dodeca, triethanolamine, emulsified silicone oil and water into the mixer and stir for 20-30min at a stirring speed of 600-800r / min to prepare a mixed solution;

[0058] S2, adding epoxy resin, calcium carbonate powder, aluminum oxide powder, phenolic resin, quartz powder and mica powder into the pulverizer and pulverizing until the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com