Post-treatment method for continuously synthesizing methyl 4-chloroacetoacetate

A technology of methyl acetate and chloroacetyl, applied in the post-processing field of continuous synthesis of methyl 4-chloroacetoacetate, can solve the problems such as inability to meet use requirements, general processing effect, poor washing effect, etc., and achieves good washing effect, Good effect and easy to achieve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

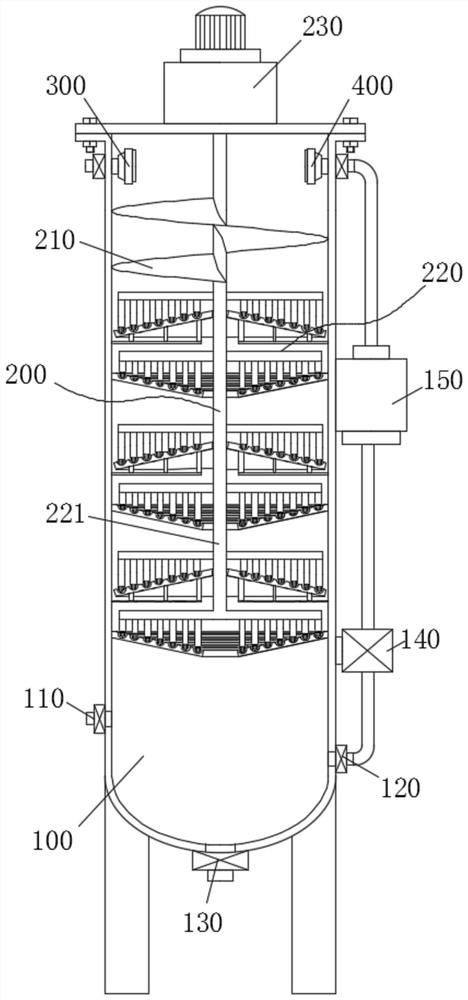

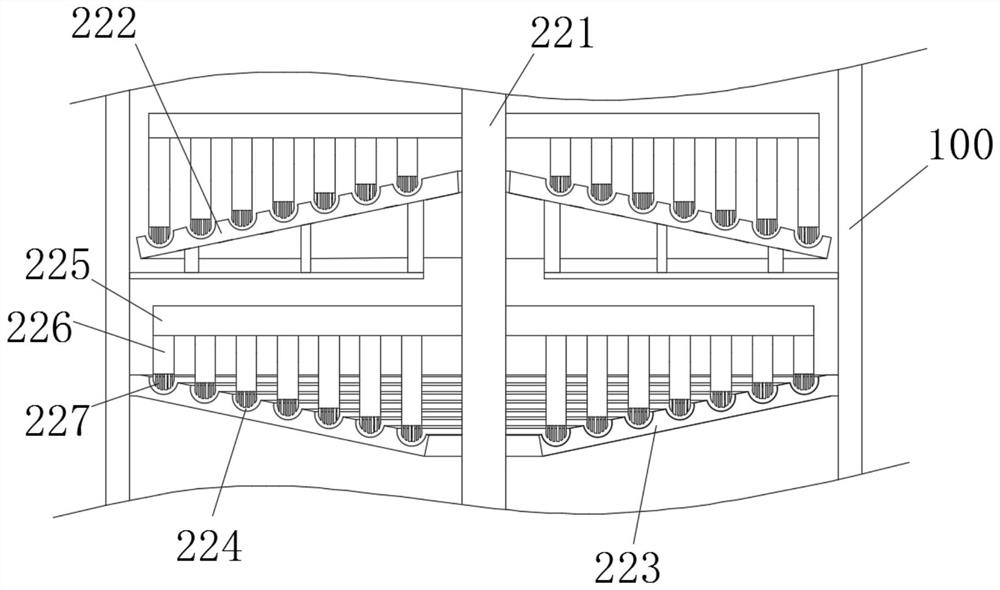

[0026] Reference attached Figure 1-3 , the present invention will be described in further detail below in conjunction with accompanying drawing:

[0027] A post-processing method for continuously synthesizing methyl 4-chloroacetoacetate, comprising the steps:

[0028] Step 1: using diketene, chlorine, dichloromethane and methanol as raw materials, through chlorination and esterification to obtain a dichloromethane solution containing methyl 4-chloroacetoacetate;

[0029] Step 2: adding a dichloromethane solution containing methyl 4-chloroacetoacetate into a water washing device to separate the aqueous solution from the organic solution;

[0030] Step 3: The organic solution is rectified to obtain the finished product of methyl 4-chloroacetoacetate.

[0031] The water washing device comprises a closed tower still 100, and the tower still 100 is arranged along the plumb direction, and the A shower nozzle 300 and the B shower nozzle that feeds into the dichloromethane solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com