High-toughness yellowing-resistant and easy-to-demold toughened nylon 6 composite material and preparation method thereof

A composite material and a technology of anti-yellowing, applied in the anti-yellowing, easy demoulding and toughening nylon 6 composite material and its preparation, high toughness field, to achieve the effects of high toughness, easy large-scale industrial production and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

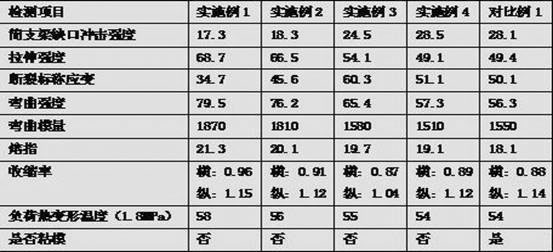

Examples

Embodiment Construction

[0015] A nylon 6 composite material with high toughness, yellowing resistance and easy release is composed of the following mass percentages:

[0016] Nylon 6 70-90%;

[0017] Toughener 5~10%

[0018] Polyethylene 4~8%

[0019] Lubricant 0.4~0.8%

[0020] Antioxidant 0.4~0.8%

[0021] Heat stabilizer 0.2~0.4%

[0022] 1. Preferably, the nylon 6 is a medium-high viscosity nylon 6 with a viscosity of 2.6 to 3.1, and it is more preferably a nylon 6 raw material of Baling Petrochemical, with a relative viscosity of 2.8. 2. Preferably, the toughening agent is horse Maleic anhydride grafted POE, the grafting rate is greater than 0.8%, and the further preferred toughening agent is the maleic anhydride grafted POE produced by Shenyang Ketong Company, and the grafting rate is 0.9%. 3. Preferably, the polyethylene is Linear low density polyethylene, more preferably the polyethylene product produced by Sichuan Petrochemical, melt flow rate 2g / 10min, elongation at break > 500%, 4, pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com