Single-control opening and closing synchronous valve set and water treatment system thereof

A water treatment system and valve group technology, applied in the field of water treatment, can solve the problems of high price, affecting the operation of the filter tank, complex structure of the tank body, etc., achieving long service life, reducing equipment investment and maintenance management costs, and reducing equipment failures rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

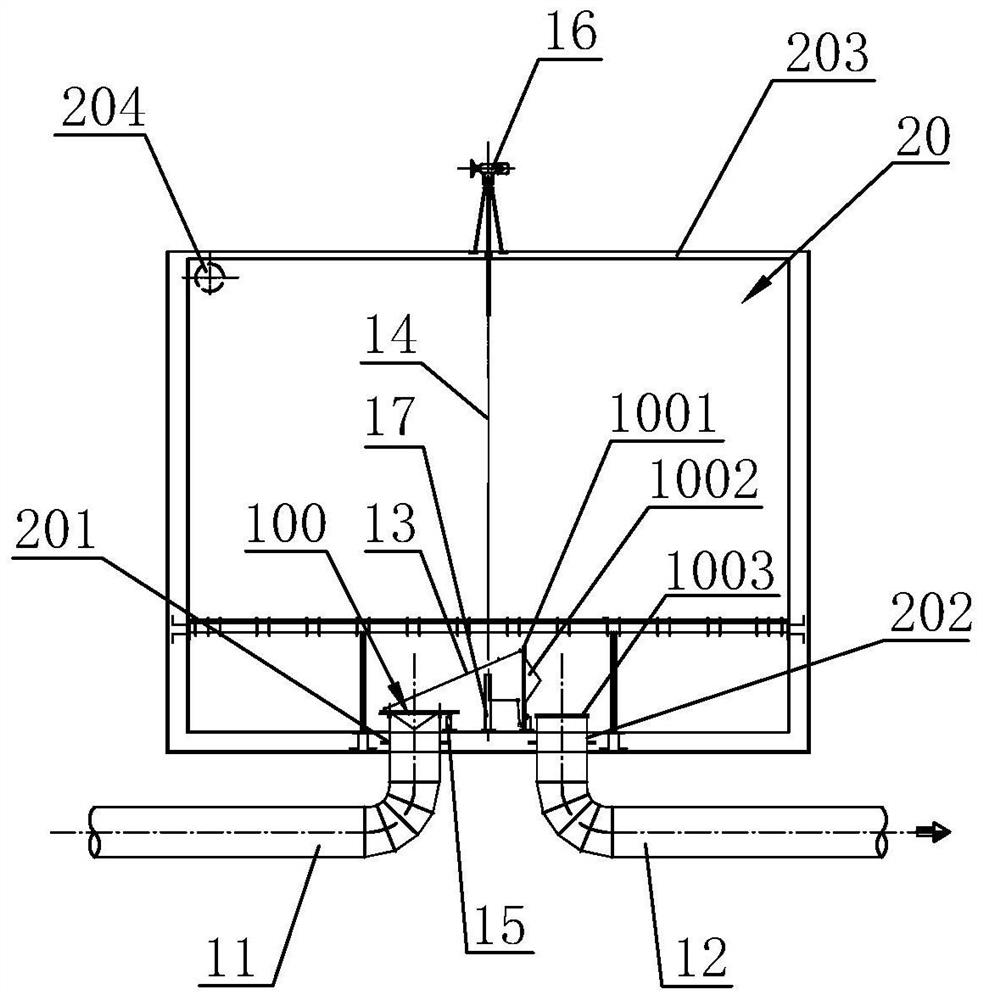

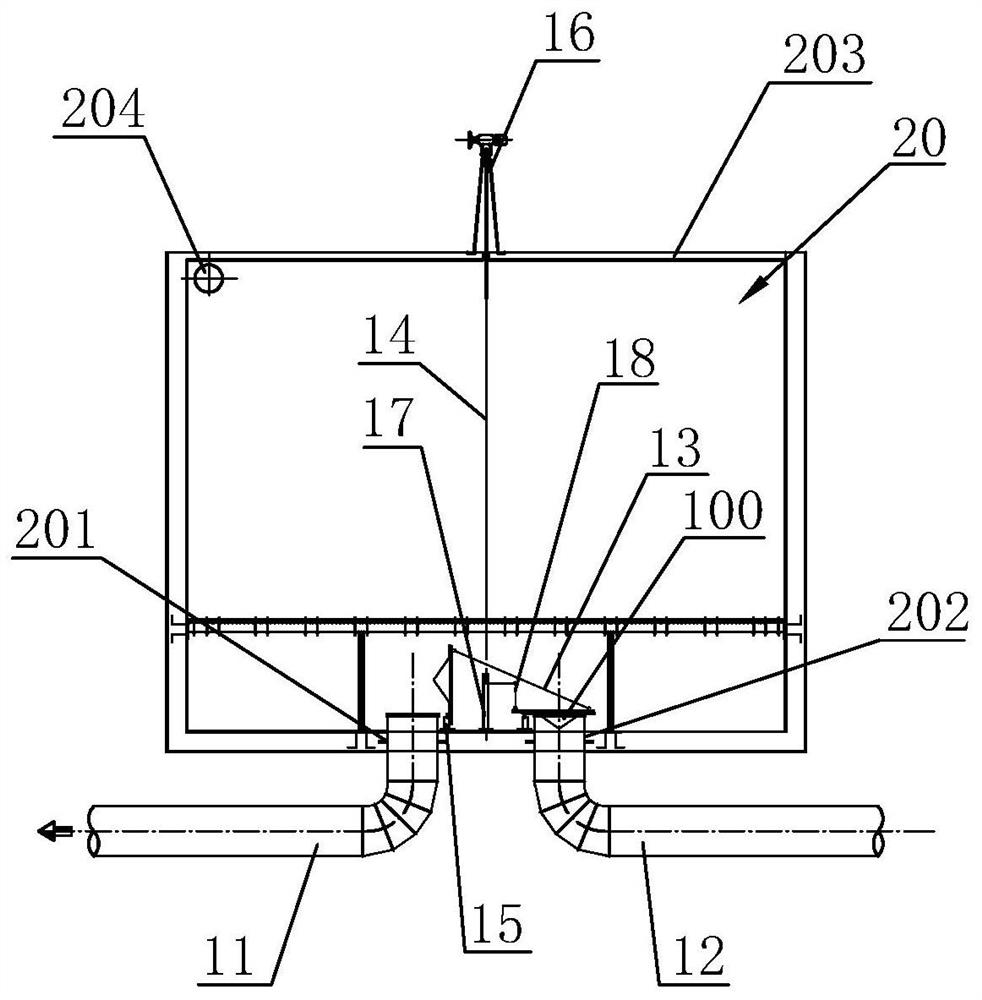

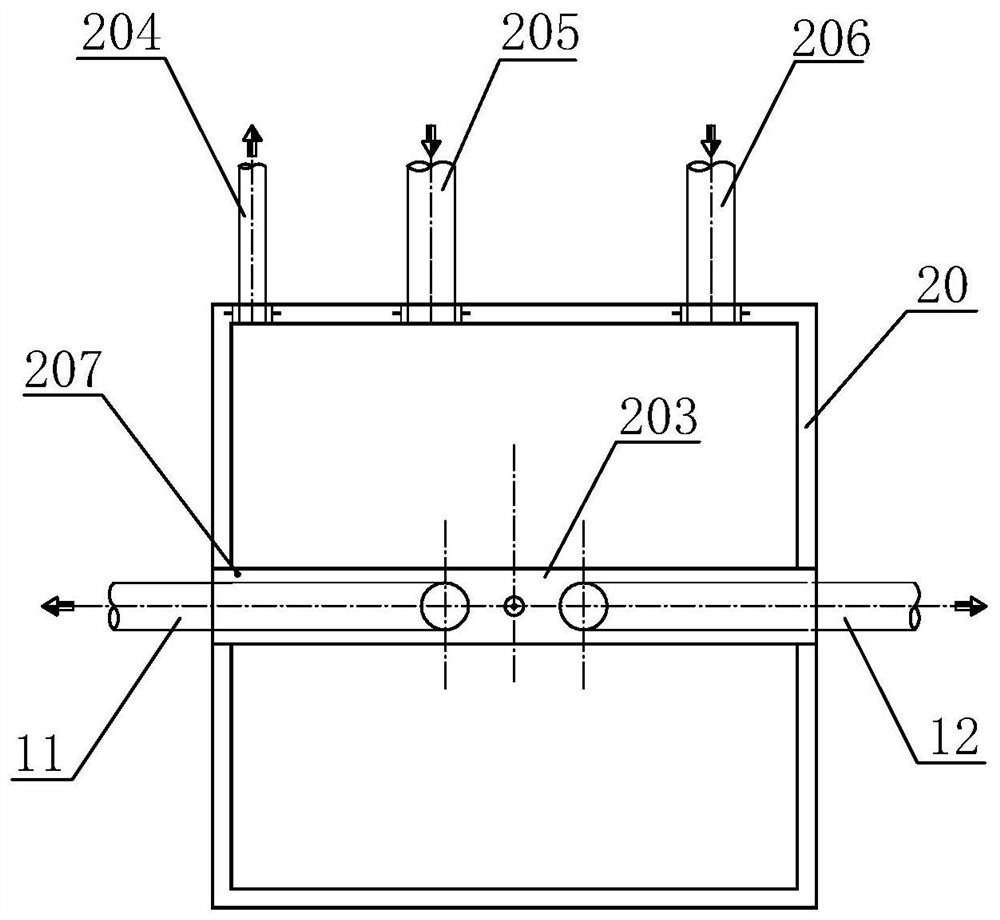

[0027] see figure 1 , image 3 or figure 2 , image 3 , the present embodiment provides a synchronous valve group of single-control one-on-one-off, including a first pipe 11 , a second pipe 12 , a valve group, a push-pull rod 13 and a control rod 14 .

[0028] The valve group includes two valves 100 with the same structure, and the two valves 100 are reversibly arranged on the opposite inner sides of the first pipeline 11 and the second pipeline 12 through hinge seats 15, so that the valves can be opposite to the first pipeline. The first pipeline and the second pipeline are opened and closed to open or close the pipelines.

[0029] Specifically, the valve 100 of this embodiment includes a valve plate 1001 and a hole recognition cone 1002. The hole recognition cone 1002 is arranged at the bottom of the valve plate 1001 and can be accommodated in the first pipe 11 or the first pipe 11. Two pipelines 12, one end of the valve plate 1001 is hinged with the hinge seat 15, as ...

Embodiment 2

[0034] In this embodiment, the valve is further designed on the basis of Embodiment 1. In order to ensure the sealing effect of the valve when it is closed, the valve 100 in this embodiment also includes an annular valve seat 1003, such as figure 1 or figure 2 As shown, the annular valve seat 1003 snaps into the edge of the mouth of the first pipe 11 or the second pipe 12 .

[0035] Preferably, the annular valve seat 1003 is a valve seat wrapped with a rubber ring, and the annular valve seat 1003 is made of Q235 material.

[0036] Preferably, the valve plate 1001 is a valve plate wrapped with a rubber pad, and the valve plate 1001 is made of S304 stainless steel.

[0037] Preferably, the hole recognition cone 1002 is integrally formed with the valve plate 1001 , and the integrally formed structure has higher structural strength.

[0038] This embodiment adopts the valve seat made of Q235 material, so that the valve plate of the valve can avoid the direct impact of the valve...

Embodiment 3

[0040]On the basis of Embodiment 1 or Embodiment 2, the top of the control rod 14 in this embodiment is connected with an electric or manual or electric-manual dual-purpose hoist 16, and an electric and manual dual-purpose hoist 16 is preferably used. The gate hoist can cooperate with the PLC controller and the filter system of the filter pool to realize automatic control of the opening / closing switching of the two valves. Compared with the traditional electric water outlet valve and drain valve, the automatic control system is greatly simplified and the Equipment failure rate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com