A method and system for testing dental restoration cad and manufacturing process fit deviations

A dental restoration and manufacturing process technology, applied in the field of dental restoration production, can solve problems such as the inability to test dental restoration CAD and manufacturing process suitability deviations, and achieve the effect of ensuring production quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

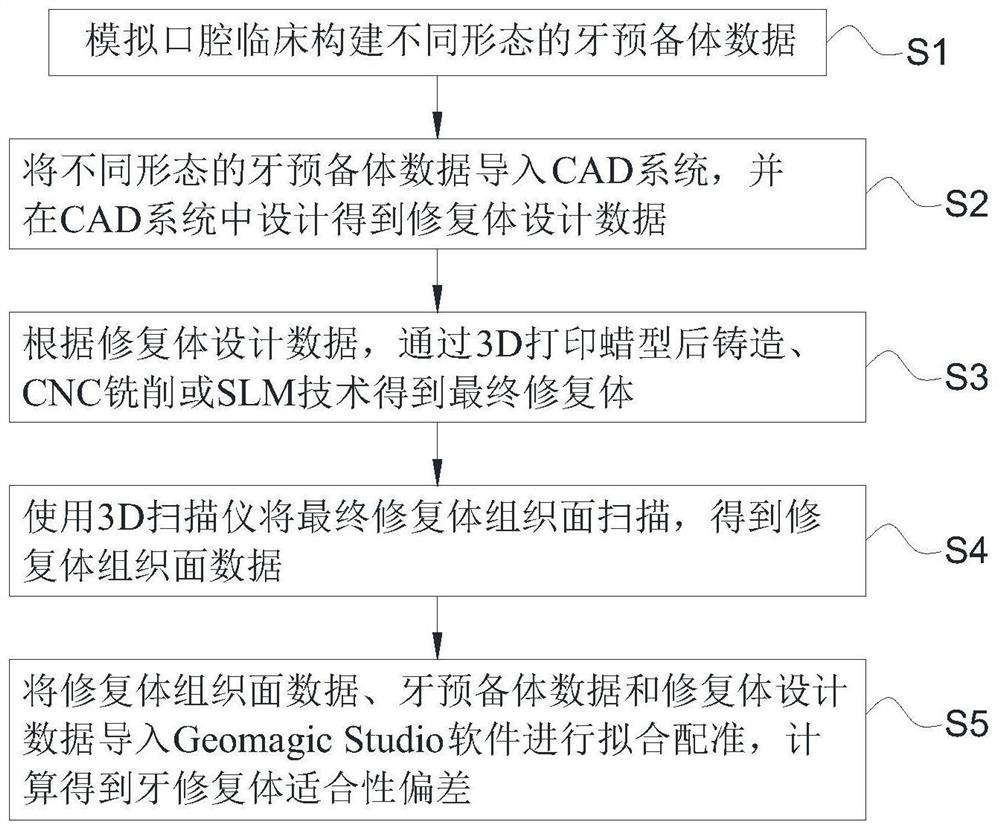

[0048] like Figure 4 As shown, the present embodiment proposes a method for testing the deviation of dental restoration CAD and manufacturing process suitability, including the following steps:

[0049] S1. Simulate oral cavity clinical construction of different forms of tooth preparation data;

[0050] S2. Import the tooth preparation data of different shapes into the CAD system, and design the restoration design data in the CAD system;

[0051]S3. According to the restoration design data, the final restoration is obtained by 3D printing wax-type casting, CNC milling or SLM technology;

[0052] S4. Use a 3D scanner to scan the tissue surface of the final restoration to obtain tissue surface data of the restoration;

[0053] S5. Import the restoration tissue surface data, tooth preparation data and restoration design data into Geomagic Studio software for fitting and registration, and calculate the suitability deviation of the tooth restoration. The restoration tissue surf...

Embodiment 2

[0083] On the basis of Example 1, this embodiment provides a system for testing the deviation of dental prosthesis CAD and suitability of the manufacturing process, and the system matches the method of Example 1.

[0084] This embodiment proposes a system for testing the deviation of dental prosthesis CAD and the suitability of the manufacturing process, including: a 3D scanner and a computer. The data model of the preparation and the tissue surface data of the final restoration are calculated to obtain the fit deviation.

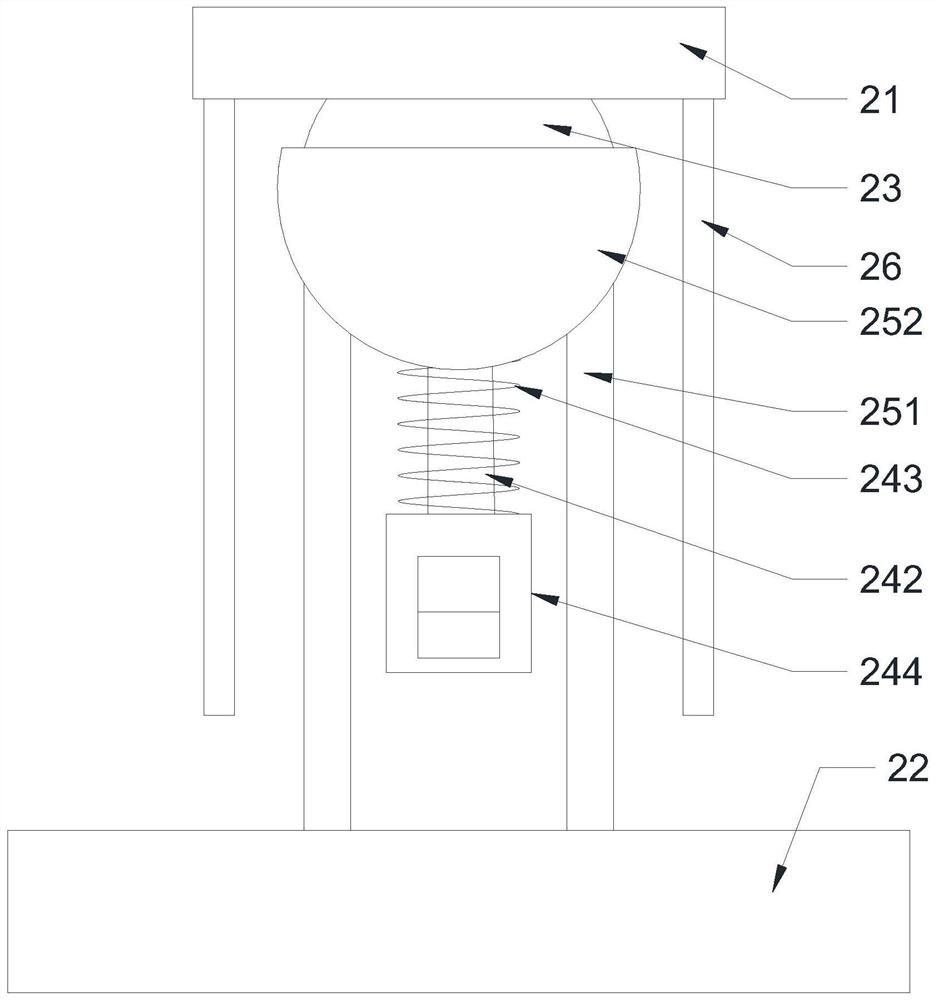

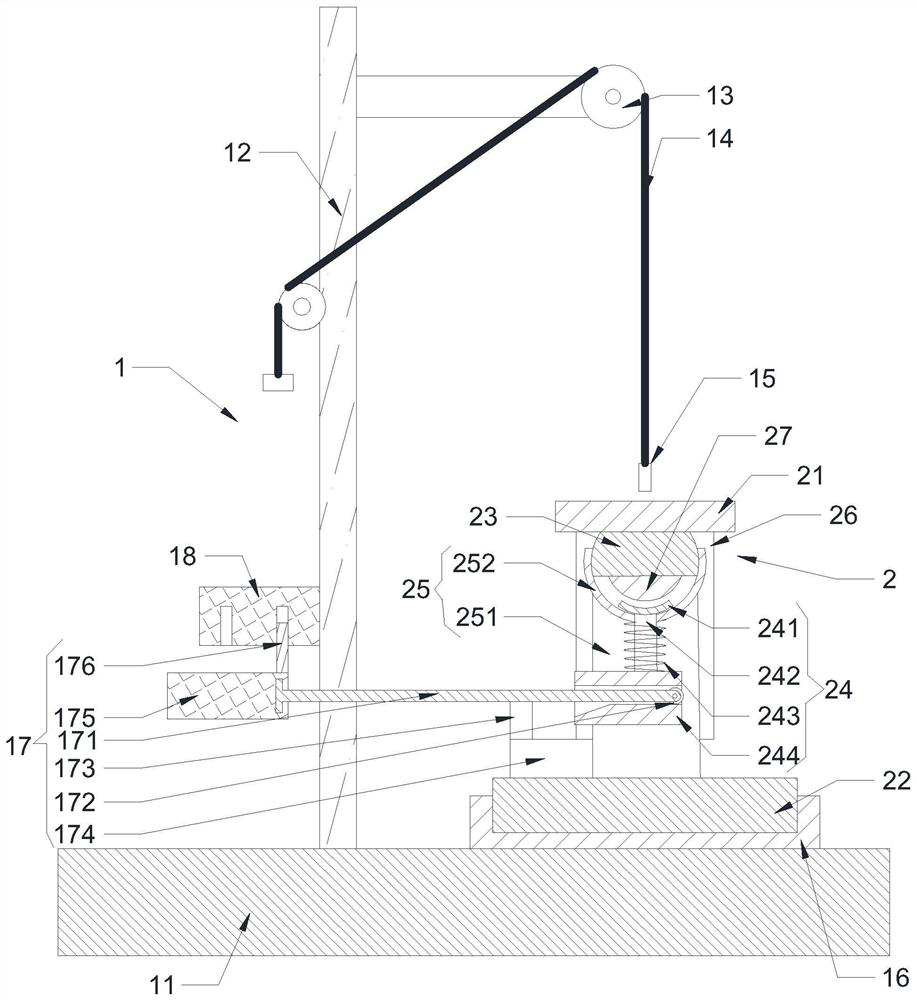

[0085] In order to design a 3D scanner with a simple structure and easy to use, the 3D scanner includes: a scanning base 2 and a scanner (not shown in the figure); the scanning base 2 is used to connect the final restoration with glue; the scanner includes: a scanning box, The scanning execution part and the driving part, the scanning execution part and the driving part are installed in the scanning box, the driving part is connected with the scanning base ...

Embodiment 3

[0098] Compared with Embodiment 1, this embodiment only has a change in step S3, that is, the way of obtaining the final restoration is different.

[0099] Step S3 comprises the following steps:

[0100] S31'. Import the prosthesis design data into the CAM system, and the CAM system uses CNC milling technology to cut the hard metal disk according to the prosthesis design data to obtain the finished prosthesis (this shape can be matched with the preparation, directly Used as a dental crown, no sintering is required);

[0101] S32', the finished restoration is in the sandblasting machine, with 50μmAl 2 o 3 The tissue surface was sandblasted for 30 seconds under the air pressure of 0.5Mpa to obtain the final restoration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com