Large-batch testing device for mechanical property degradation detection of aircraft pipeline gasket

A test device, a mass-volume technology, applied in the direction of measuring devices, using stable tension/compression testing material strength, scientific instruments, etc., can solve performance degradation, unlined vibration isolation performance and extrusion deformation testing, difficult lining Pad dynamic mechanical performance testing and other issues to achieve the effect of saving test time, good reliability and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

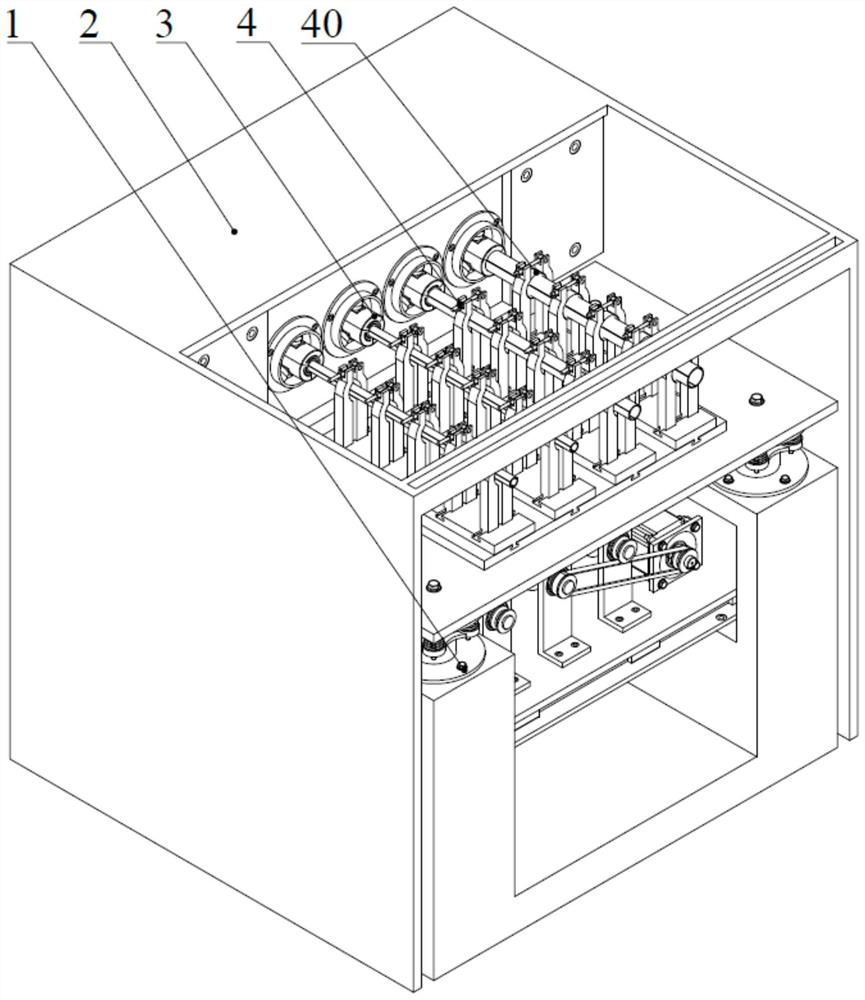

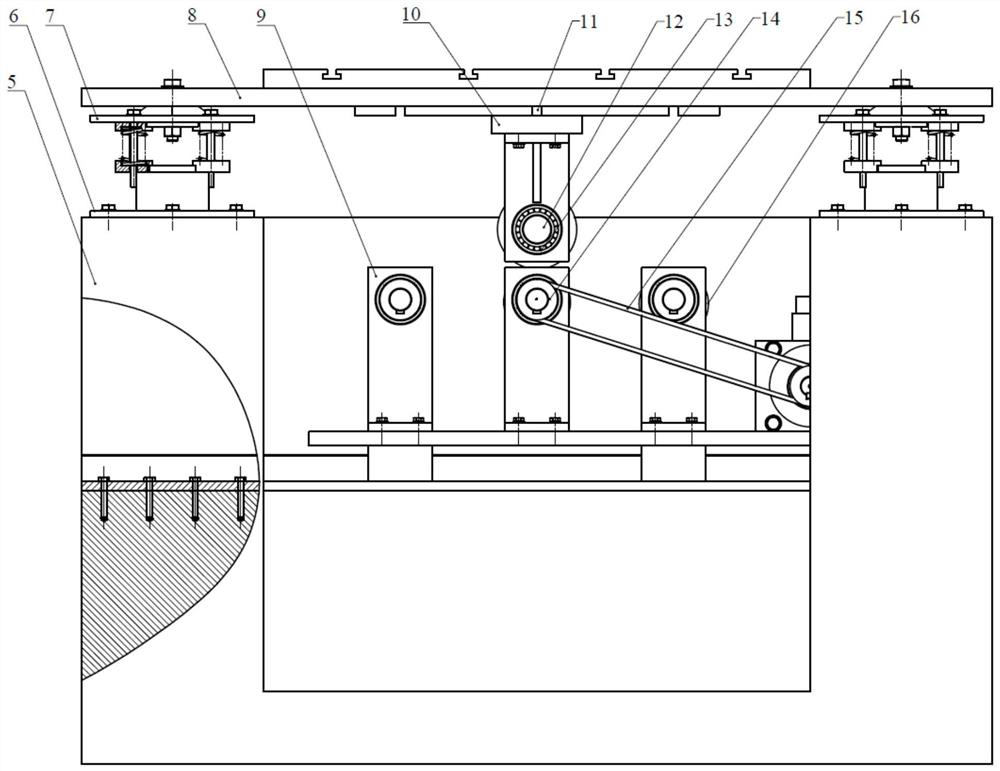

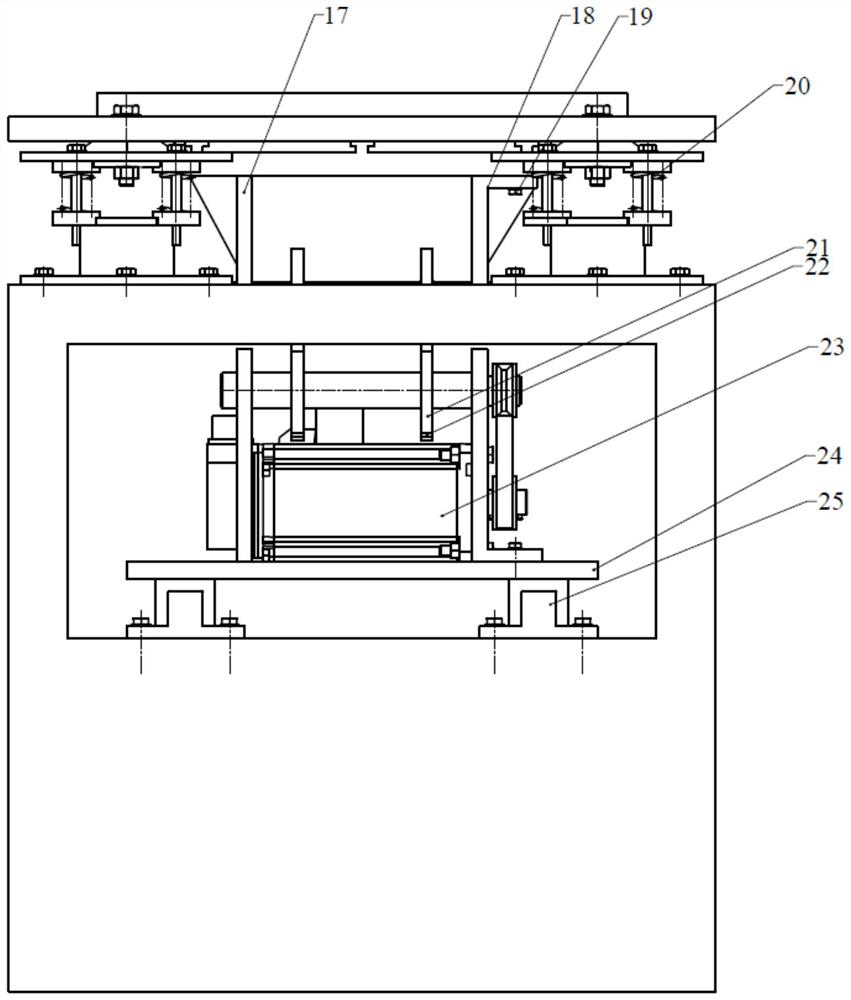

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the accompanying drawings. figure 1 It is a schematic diagram of the three-dimensional structure of the testing device of the present invention, figure 2 It is a structural schematic diagram of the eccentric excitation platform of the test device of the present invention, image 3 It is the left view of the eccentric excitation platform of the test device of the present invention, Figure 4 It is a structural schematic diagram of a large batch of fixtures for the testing device of the present invention, Figure 5 It is a schematic diagram of the installation of a large batch of fixtures for the test device of the present invention, Image 6 It is a schematic diagram of the three-dimensional structure of the test device of the present invention, which divides the tube path into three equal parts and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com