Method for detecting copper in electronic waste

A technology of electronic waste and detection method, which is applied in the fields of chemistry and metallurgy, can solve the problems of repeatability and poor accuracy of analysis results, and achieve the effect of objective and true analysis results, high efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

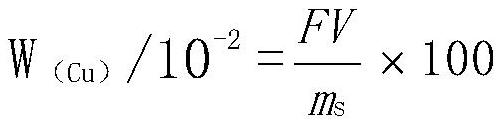

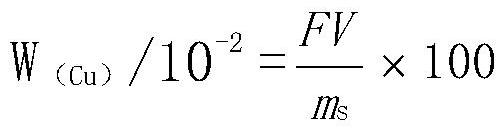

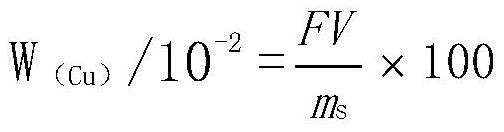

Image

Examples

Embodiment

[0028] Technical method of the present invention, the steps are as follows:

[0029] 1) Weighing: Put a piece of filter paper on the electronic balance, weigh 0.20~0.30g (accurate to 0.0001g) of the sample on the filter paper, fold and compact the filter paper and put it into a 50mL porcelain crucible with 5 layers of filter paper . The sample is wrapped with filter paper to prevent the sample from splashing loss and sticking to the bottom of the crucible during carbonization and ashing.

[0030] 2) Carbonization: Put the porcelain crucible containing the sample into the muffle furnace at room temperature, close the furnace door, set the temperature to 500°C, turn on the muffle furnace to burn, and heat up to 500°C within 30-40min, and the carbonization will be destroyed at low temperature Organic matter (polycarbonate resin, polyethylene, etc.), convert the organic matter in the sample into carbonaceous, when the temperature reaches 500 ° C, keep it warm for 15 minutes. Slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com