Method for reinforced washing and purification of catering lampblack in virtue of loofah sponge and application thereof

A technology of loofah and catering, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, and can solve the problems of few researches on the application of loofah

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

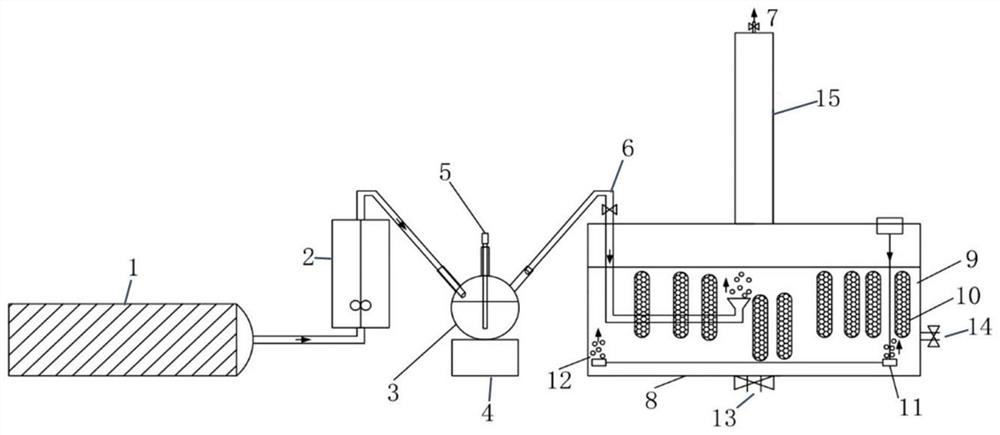

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will now be further described.

[0016] (1) Wash the loofah with a diameter of 6 cm and a length of 26-30 cm, purchased in Jinan, Shandong Province, with deionized water for 2-3 times, then put it in an oven, adjust the temperature at 105 ℃ and keep it for 8 hours for drying treatment, after cooling Store in a desiccator for later use.

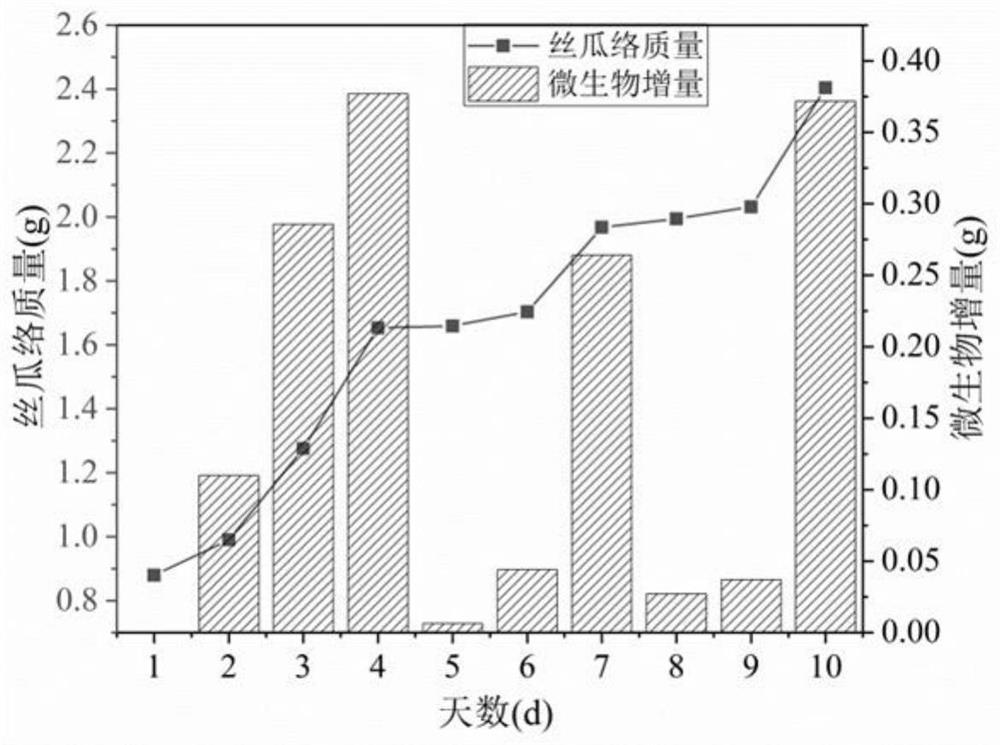

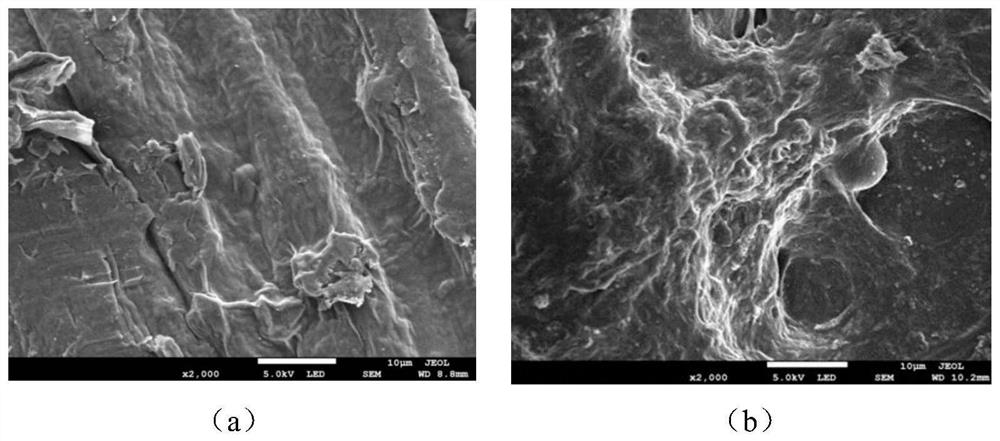

[0017] (2) Take out 9 loofahs processed according to the method (1) from the drying box, and fix them in the domesticated and mature activated sludge washing liquid in the washing tank with iron wire, the filling degree is 70%. At the same time, take out 1-2 pieces of loofah that have been processed according to method (1), cut and weigh 10 pieces of loofah pieces (diameter 6cm, height 3cm) with the same specifications and sizes and weighing 0.8800g, and place them in the active area. Completely submerged in the sludge. The natural loofah has a rough surface and a natural network structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com