Vinyl ester flame-retardant resin containing polyester structure and preparation method thereof

A vinyl ester and flame retardant resin technology, applied in the field of vinyl ester resin, can solve the problems of general compactness and fatigue resistance, lack of cross-linking points in the main chain, single cross-linking density, etc., and achieve good fatigue resistance and Flame retardant effect, saving manpower and equipment cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of the vinyl ester flame retardant resin containing polyester structure, comprises the following steps:

[0034] S1, first carry out polycondensation reaction with dibasic carboxylic acid and / or dibasic carboxylic acid anhydride with dibasic alcohol, make the unsaturated polyester prepolymer that end group on both sides all contains carboxyl group; Control the reaction temperature of described polycondensation reaction to be 130~190℃;

[0035] 【At least one halogen in the structure】

[0036] S2, then combine the unsaturated polyester prepolymer obtained in step S1 with carboxyl groups at the end groups on both sides, with halogen-containing or halogen-free epoxy resin, and unsaturated monobasic acid containing ethylenic bonds, in a catalyst, In the presence of a polymerization inhibitor, ring-opening polymerization of epoxy groups is carried out at a reaction temperature of 105-135 ° C to form vinyl ester resin; then dissolved in reactive m...

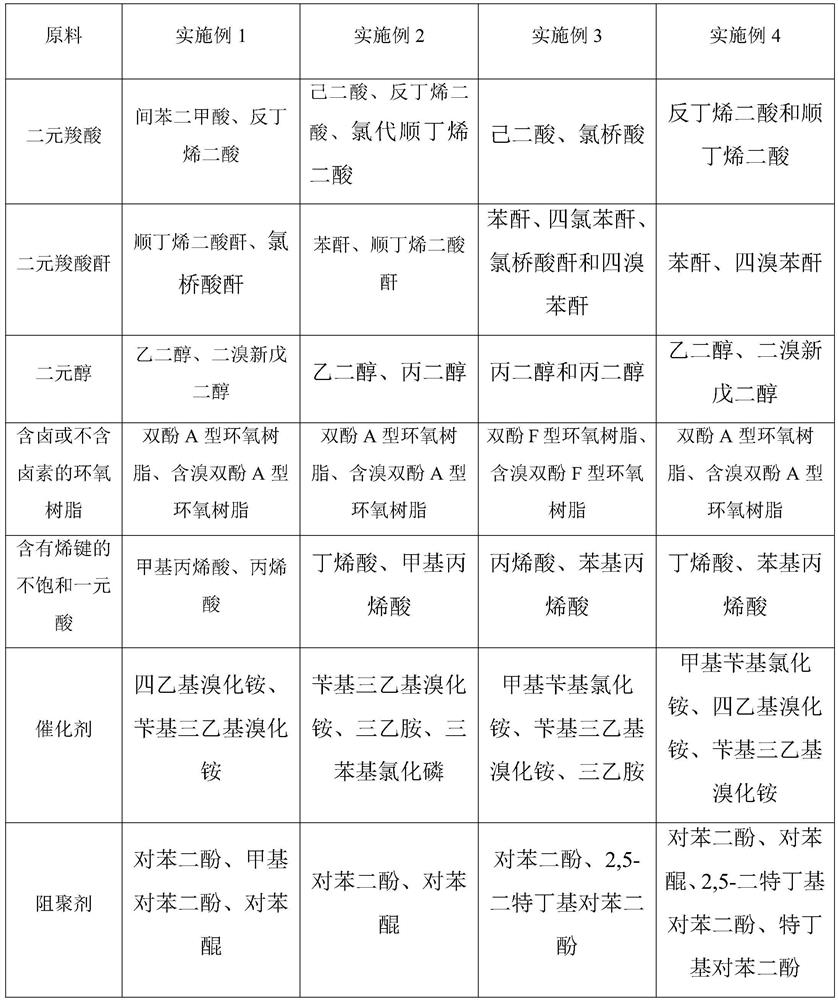

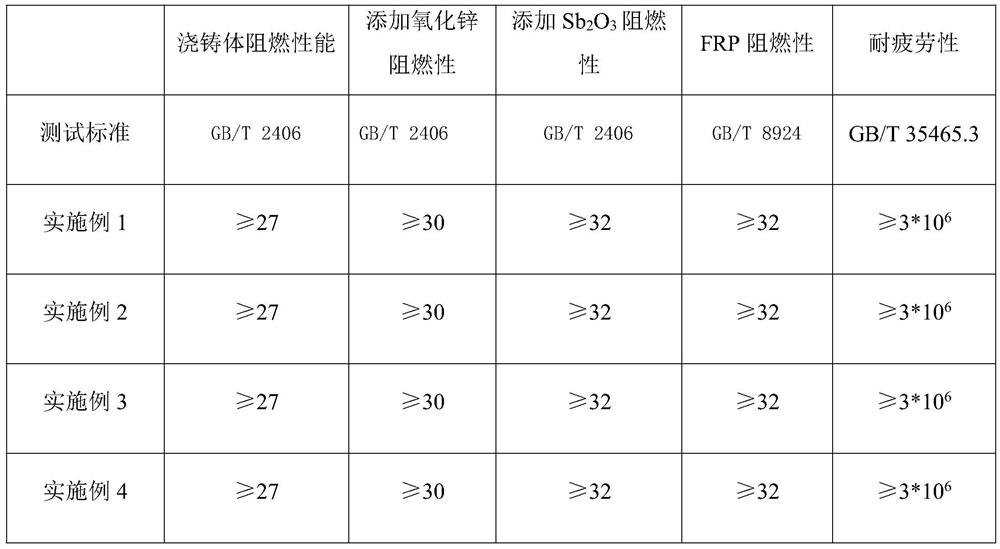

Embodiment 1

[0053] A kind of preparation method of the vinyl ester flame retardant resin containing polyester structure, comprises the following steps:

[0054] S1, first carry out polycondensation reaction with dibasic carboxylic acid and / or dibasic carboxylic acid anhydride with dibasic alcohol, make the unsaturated polyester prepolymer that end group on both sides all contains carboxyl group; Control the reaction temperature of described polycondensation reaction to be 130°C;

[0055] S2, then combine the unsaturated polyester prepolymer obtained in step S1 with carboxyl groups at the end groups on both sides, with halogen-containing or halogen-free epoxy resin, and unsaturated monobasic acid containing ethylenic bonds, in a catalyst, In the presence of a polymerization inhibitor, ring-opening polymerization of epoxy groups is carried out at a reaction temperature of 105°C to form vinyl ester resin; then dissolved in reactive monomers containing unsaturated double bonds, the temperatur...

Embodiment 2

[0061] A kind of preparation method of the vinyl ester flame retardant resin containing polyester structure, comprises the following steps:

[0062] S1, first carry out polycondensation reaction with dibasic carboxylic acid and / or dibasic carboxylic acid anhydride with dibasic alcohol, make the unsaturated polyester prepolymer that end group on both sides all contains carboxyl group; Control the reaction temperature of described polycondensation reaction to be 190°C;

[0063] S2, then combine the unsaturated polyester prepolymer obtained in step S1 with carboxyl groups at the end groups on both sides, with halogen-containing or halogen-free epoxy resin, and unsaturated monobasic acid containing ethylenic bonds, in a catalyst, In the presence of a polymerization inhibitor, ring-opening polymerization of epoxy groups is carried out at a reaction temperature of 135°C to form vinyl ester resin; then dissolved in reactive monomers containing unsaturated double bonds, the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com