Recycling treatment method of waste plastic particles

A technology of waste plastics and treatment methods, which is applied in the field of plastics and can solve the problems of poor physical and chemical properties, poor uniformity and interface compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] see Figure 1-15 As shown, this embodiment is a method for reusing waste plastic particles, comprising the following steps:

[0057] Step 1: Disposal of waste plastic particles:

[0058] S1. Heating and drying treatment: Put the waste plastic particles into the drying box for heating and drying treatment. During this period, the temperature for keeping dry is 90-95°C and the duration is 50-60min. After the drying is completed, dry plastic particles are obtained;

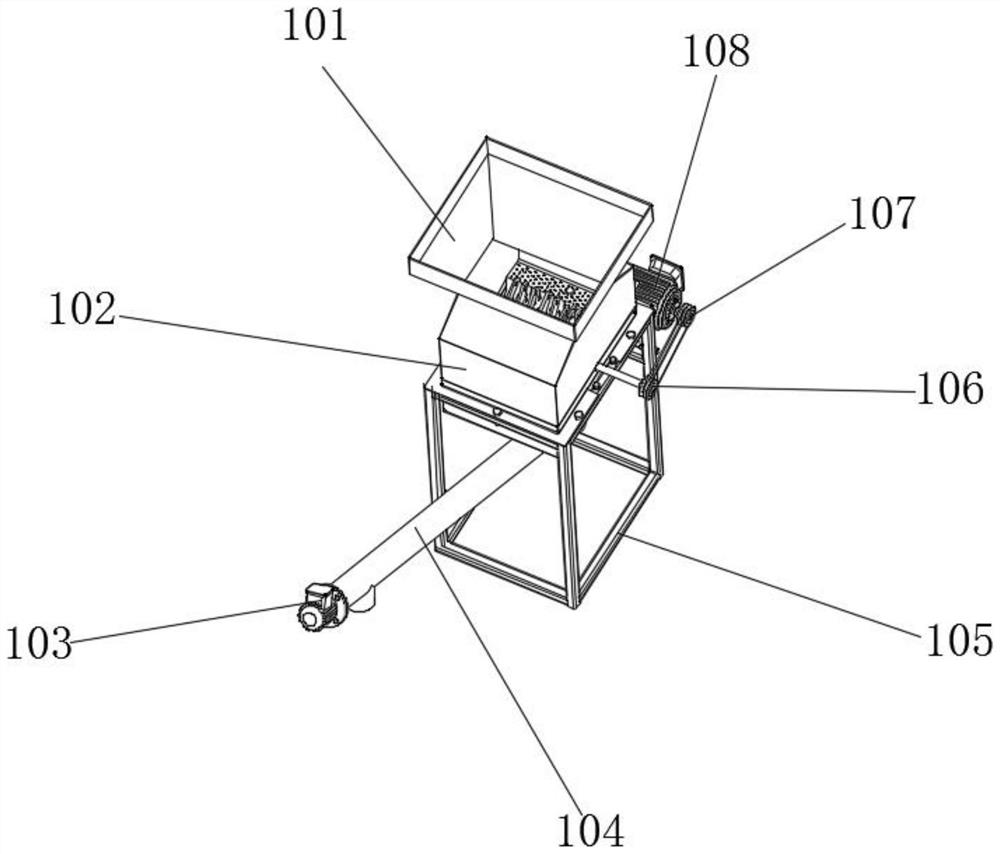

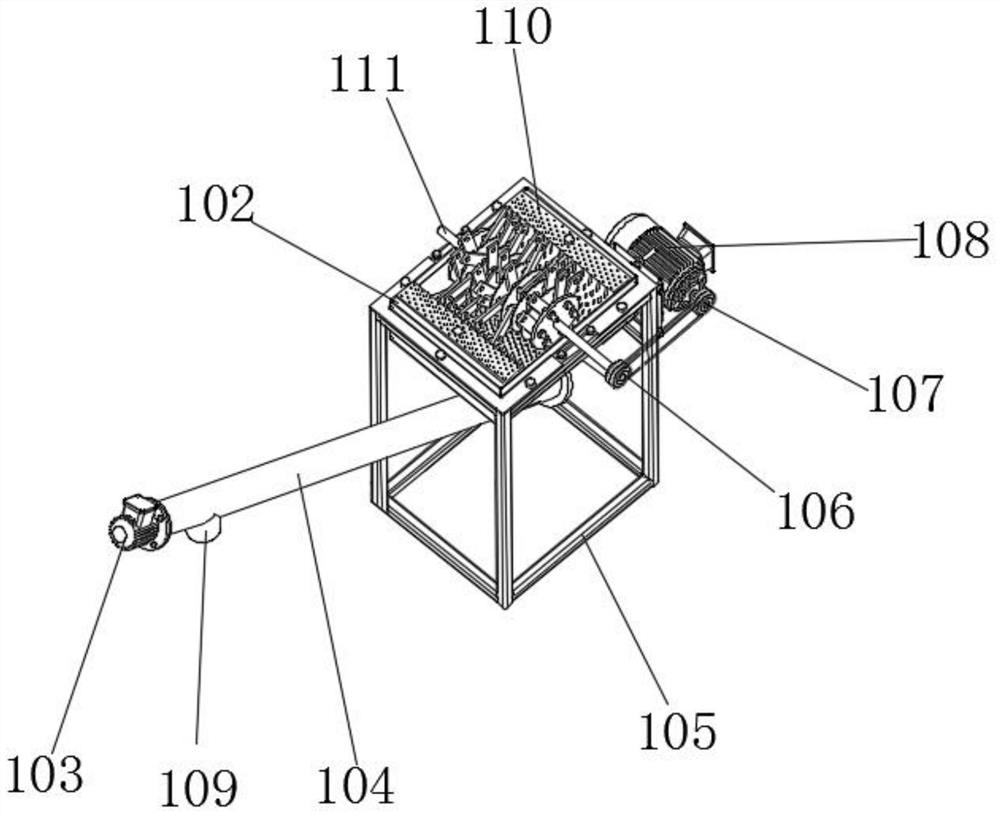

[0059] S2. Crushing into powder: put the dry plastic particles into the hopper 101 of the pulverizing conveying mechanism 100 of the recycling processing equipment, start the driving motor 108, and the driving motor 108 drives the linkage shaft through the driving pulley 107 and the driven pulley 106 111 rotation, the positioning disc 112 and the positioning shaft 113 drive several crushing blades 114 to rotate, and the rotating several crushing blades 114 crush the dry plastic particles into powder, and the ...

Embodiment 2

[0073] The difference between this example and Example 1 is that the wood-plastic material in step 2 includes the following components in parts by weight: 100 parts of waste plastic powder, 80 parts of wood fiber powder, 90 parts of clay, and 8 parts of plasticizer , 6 parts of stabilizer, 1.5 parts of PE wax, 1.5 parts of stearic acid, 10 parts of foam regulator, 1.5 parts of foaming agent, and 0.25 parts of dispersant.

[0074] The performance of the wood-plastic material in Example 2 is tested, and the test results are: maximum load 6123N, bending strength 39.8MPa, bending modulus 5192MPa, density 1.4g / cm 3 , Water absorption 0.10%.

Embodiment 3

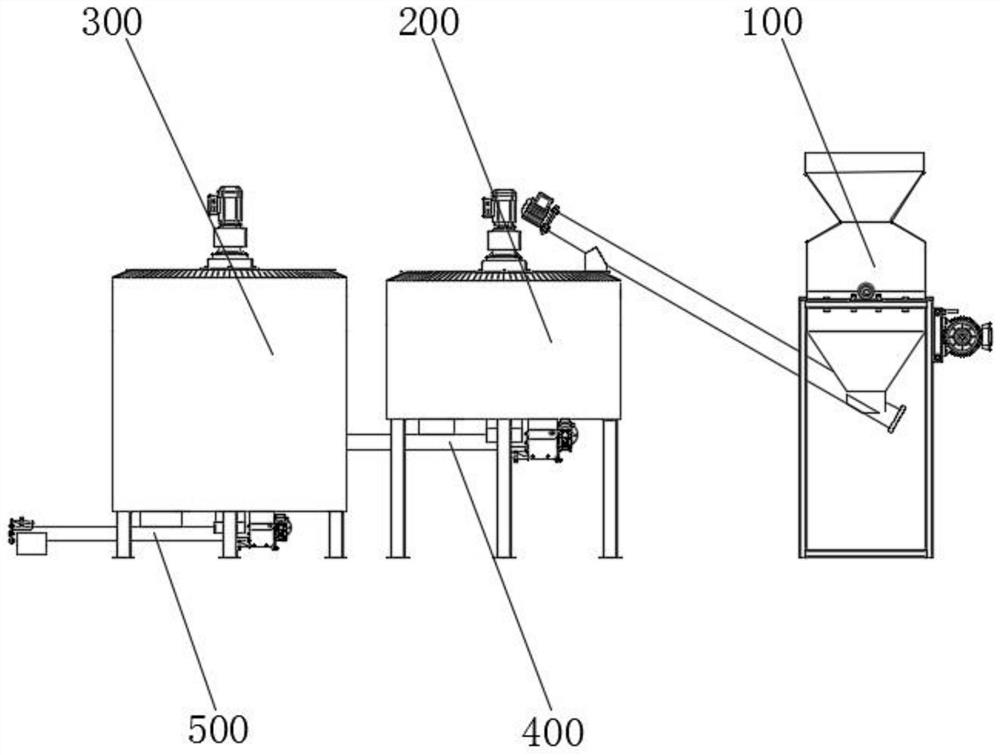

[0076] see Figure 1-15 As shown, the recycling processing equipment in this embodiment includes a crushing and conveying mechanism 100, a first mixing mechanism 200, a second mixing mechanism 300, a first feeding mechanism 400, and a second feeding mechanism 500. The crushing and conveying mechanism One end of 100 is connected to the top side of the first mixing mechanism 200, the bottom of the first mixing mechanism 200 is equipped with a first delivery mechanism 400, and one end of the first delivery mechanism 400 is connected to one side of the second mixing mechanism 300. side, the bottom of the second mixing mechanism 300 is equipped with a second delivery mechanism 500;

[0077] Wherein, the crushing conveying mechanism 100 includes a hopper 101, a crushing bin 102, a conveying motor 103, a conveying pipe 104, a support frame 105, a driven pulley 106, a driving pulley 107, a driving motor 108, a powder conveying pipe 109, and an arc sieve. Plate 110, linkage shaft 111,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com