Anti-corrosion and anti-loosening treatment method for metal part fastening connection joint surface coating

A technology of fastening connection and processing method, which is applied to the device, coating, anti-corrosion coating and other directions of applying liquid to the surface, which can solve the problems of loosening and loosening of metal parts, so as to improve the tightness, hardness, and prevent loosening. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Anti-corrosion and anti-loosening treatment method for the shaft-pin joint surface coating of commercial vehicle thrust rod assembly

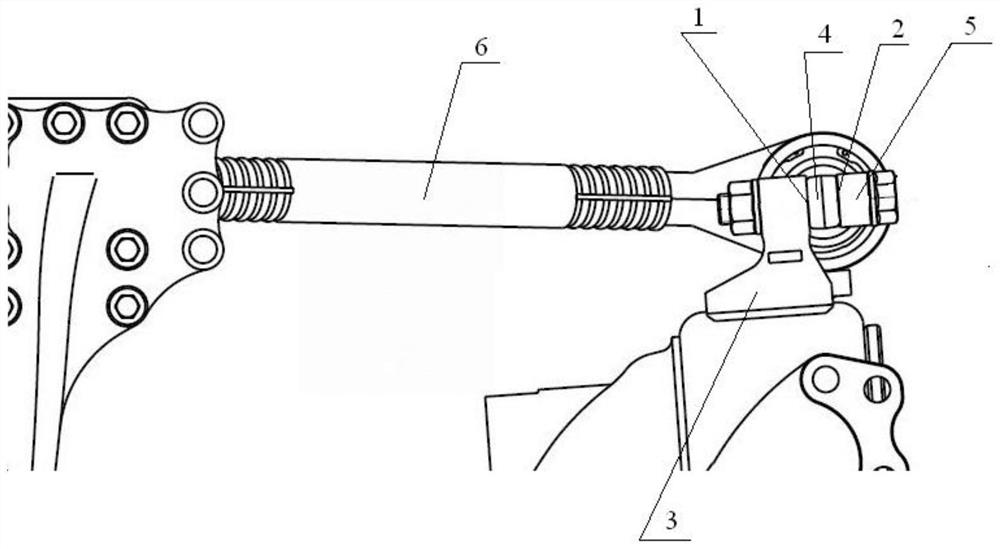

[0026] combine figure 1 As shown, the thrust rod assembly is an important balance and force-bearing part. The thrust rod assembly includes a thrust rod 6 and a shaft pin 4, which are tightly connected with the drive axle thrust rod bracket 3 through bolts 5. After the bolt 5 is tightened, the shaft pin 4 The assembly first joint surface 1 of the shaft pin 4 is jointed with the drive axle thrust rod bracket 3, and the second joint joint surface 2 of the shaft pin 4 is jointed with the bolt 5. In order to improve the corrosion resistance of the shaft pin 4, it is generally necessary to connect Surface 1 and the second assembly surface 2 are coated with an anti-corrosion coating, but the coating is likely to cause the problem of bolt 5 loosening during driving. The purpose of the present invention is to prevent the phenomenon of b...

Embodiment 2

[0031] Embodiment 2 The anti-corrosion and anti-loosening treatment method of the axle wheel hub joint surface coating

[0032] The assembly joint surface between the axle hub and the wheel is a typical fastener connection joint surface, the reliability of the fastening connection is extremely important, and the bolt fastening connection between the axle hub and the wheel is prone to loosening, resulting in bolt breakage. Accidents such as wheel falling off. The method for processing the joint surface of the axle hub comprises the steps of:

[0033] (1) Pre-painting treatment: degrease, degrease and phosphate the axle hub joint surface with a roughness less than 8 microns. The degreasing process ensures that the parts and fastening joint surfaces are free of oil, and the phosphating film formed by the phosphating process can be compared with The coating achieves a good matching, in which the phosphating film thickness is 2 μm to 4 μm, and the film weight is 1g / m 2 ~3g / m 2 ....

Embodiment 3

[0037] Example 3 Anti-corrosion and anti-loosening treatment method of joint surface coating of commercial vehicle suspension bracket assembly

[0038] (1) Pre-painting treatment: degrease, degrease and phosphate the joint surface of the suspension bracket assembly with a roughness less than 10 microns. The film can be well matched with the protective coating, and the thickness of the phosphating film is 2 μm to 4 μm, and the film weight is 1g / m 2 ~3g / m 2 .

[0039] (2) Coating: Cathodic electrophoretic coating is adopted. The components of the coating include 65% epoxy resin and epoxy acrylic resin and 35% pigments and fillers. The pigments and fillers contain 0.4% molybdenum disulfide and 0.7% flake graphite The curing temperature of the coating is 180°C for 30 minutes. After curing, the thickness of the coating is 28 microns, the thickness uniformity is ±3 μm, the salt spray resistance of the coating is 480 hours, and the hardness of the coating is H. The coefficient of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap