Production method of high-efficiency electrical steel

A production method and technology for electrical steel, applied in the field of electrical steel production, can solve the problems of insignificant magnetic induction effect of performance improvement, and achieve the effects of reducing iron loss, improving magnetic induction performance, and improving stamping efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

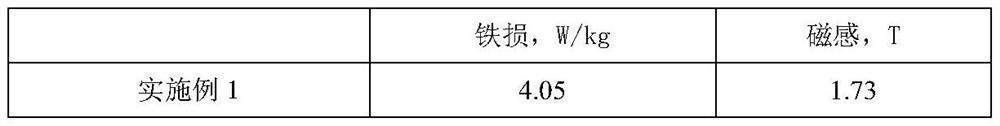

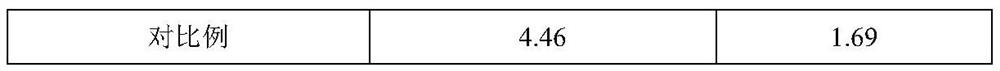

Embodiment 1

[0017] The chemical composition of high-efficiency electrical steel is: C: 0.002%, Si: 0.80%, Mn: 0.22%, P: 0.011%, S: 0.003%, Als: 0.22%, N: 0.0013%, the rest are iron and inevitable impurity elements.

[0018] The production method of high-efficiency electrical steel includes the following steps:

[0019] 1) Smelting and continuous casting: adopt converter smelting, RH vacuum refining treatment, control the composition of molten steel according to the above requirements, and cast into 230mm thick slab;

[0020] 2) The hot-rolled slab is rolled at a temperature of 1130°C, rough-rolled to a thickness of 38mm, and then rolled in a finishing mill. The finishing rolling temperature is 980℃, the final rolling temperature is 880℃, and the coiling temperature is 720℃;

[0021] 3) Cold-rolled to 0.16mm after pickling;

[0022] 4) Continuous annealing at 870°C × 1min (continuous annealing at 870°C, 1 minute in the furnace) after cold rolling.

[0023] Among them, after the continu...

Embodiment 2

[0029] The chemical composition of high-efficiency electrical steel is: C: 0.002%, Si: 0.60%, Mn: 0.25%, P: 0.013%, S: 0.004%, Als: 0.25%, N: 0.0014%, the rest are iron and inevitable impurity elements.

[0030] The production method of high-efficiency electrical steel includes the following steps:

[0031] 1) Smelting and continuous casting: adopt converter smelting, RH vacuum refining treatment, control the composition of molten steel according to the above requirements, and cast into 230mm thick slab;

[0032] 2) The hot-rolled slab is rolled at a temperature of 1130°C, rough-rolled to a thickness of 38mm, and then rolled in a finishing mill. The finishing rolling temperature is 990℃, the final rolling temperature is 870℃, and the coiling temperature is 730℃;

[0033] 3) Cold-rolled to 0.21mm after pickling;

[0034] 4) Continuous annealing at 850℃×1min after cold rolling.

[0035] Among them, after the continuous annealing of the cold-rolled steel strip, the surface of...

Embodiment 3

[0040] The chemical composition of high-efficiency electrical steel is: C: 0.002%, Si: 0.80%, Mn: 0.22%, P: 0.011%, S: 0.003%, Als: 0.22%, N: 0.0013%, the rest are iron and inevitable impurity elements.

[0041] The production method of high-efficiency electrical steel includes the following steps:

[0042] 1) Smelting and continuous casting: adopt converter smelting, RH vacuum refining treatment, control the composition of molten steel according to the above requirements, and cast into 230mm thick slab;

[0043] 2) The hot-rolled slab is rolled at a temperature of 1130°C, rough-rolled to a thickness of 38mm, and then rolled in a finishing mill. The finishing rolling temperature is 980℃, the final rolling temperature is 880℃, and the coiling temperature is 720℃;

[0044] 3) Cold-rolled to 0.11mm after pickling;

[0045] 4) Continuous annealing at 850℃×1min after cold rolling.

[0046] Among them, after the continuous annealing of the cold-rolled steel strip, the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com