Production process used for forming non-woven fabric

A production process, non-woven technology, applied in the direction of filament/thread forming, filament forming treatment, textile/flexible product manufacturing, etc. The number of defects, the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

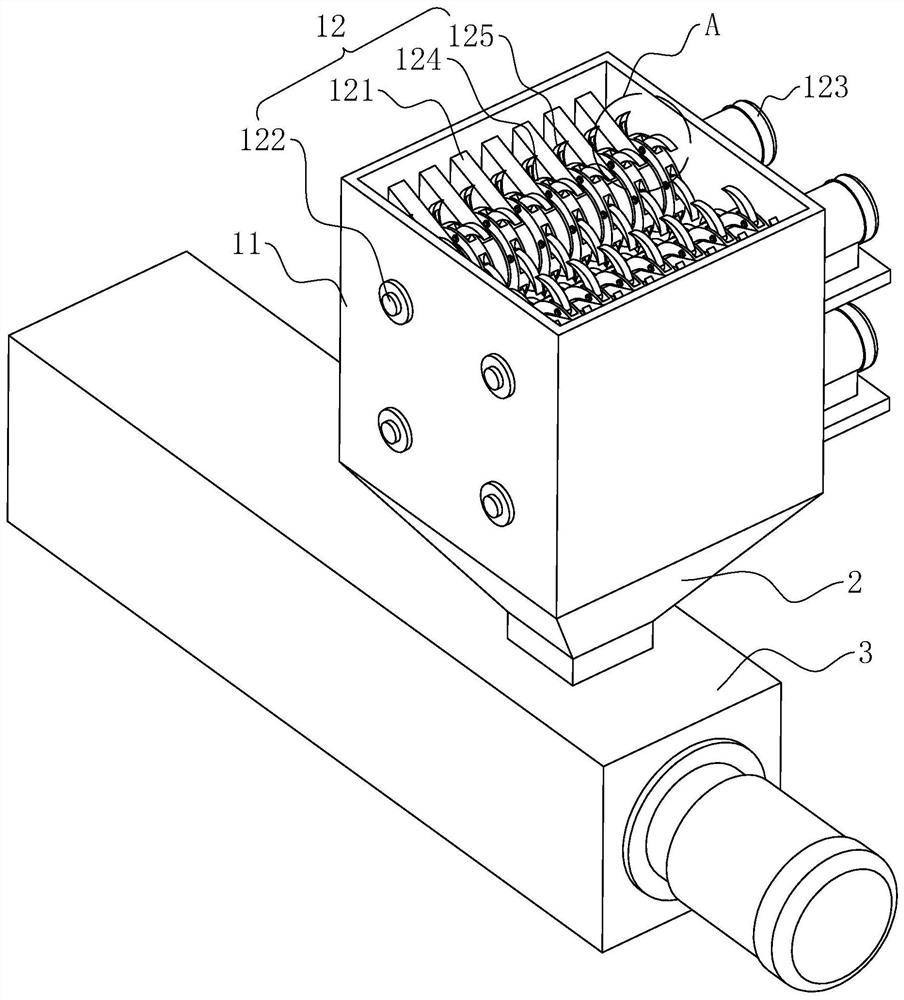

[0050] The following is attached Figure 1-5 The application is described in further detail.

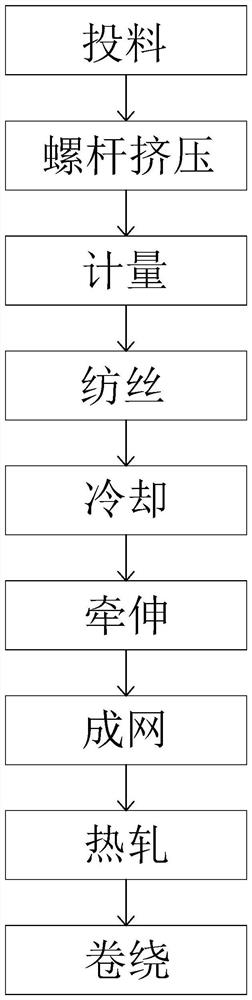

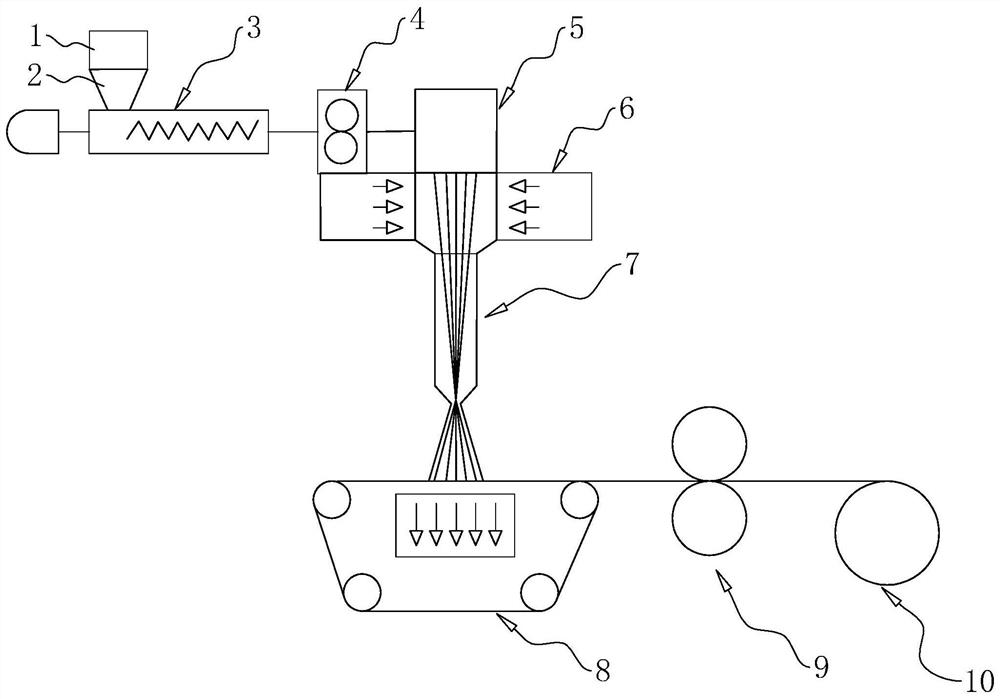

[0051] The embodiment of the present application discloses a production process for forming non-woven fabrics. refer to figure 1 and figure 2 , the production process includes the following steps:

[0052] Feeding: Send the sliced polypropylene, additives, color masterbatch, and functional fibers into the crushing and stirring device 1 to crush them into raw materials with smaller particle sizes. Brightening agents, softeners and compatibilizers are selected as additives, and blue and green colors can be selected for masterbatches according to the design requirements of non-woven fabrics. 80 parts by mass of polypropylene, 30 parts by mass of polypropylene fiber, 30 parts by mass of polyester fiber, 30 parts by mass of carbon fiber, 30 parts by mass of nylon chemical fiber, and 30 parts by mass of viscose chemical fiber can be used to reinforce the formed non-woven The streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com