Garbage combustion flue gas waste heat collection and discharging pipeline

A flue gas waste heat and waste combustion technology, which is applied in the direction of combustion method, combustion type, and combustion technology mitigation, can solve the problems of reduced efficiency of waste heat utilization, and achieve the effect of improving adsorption effect and collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

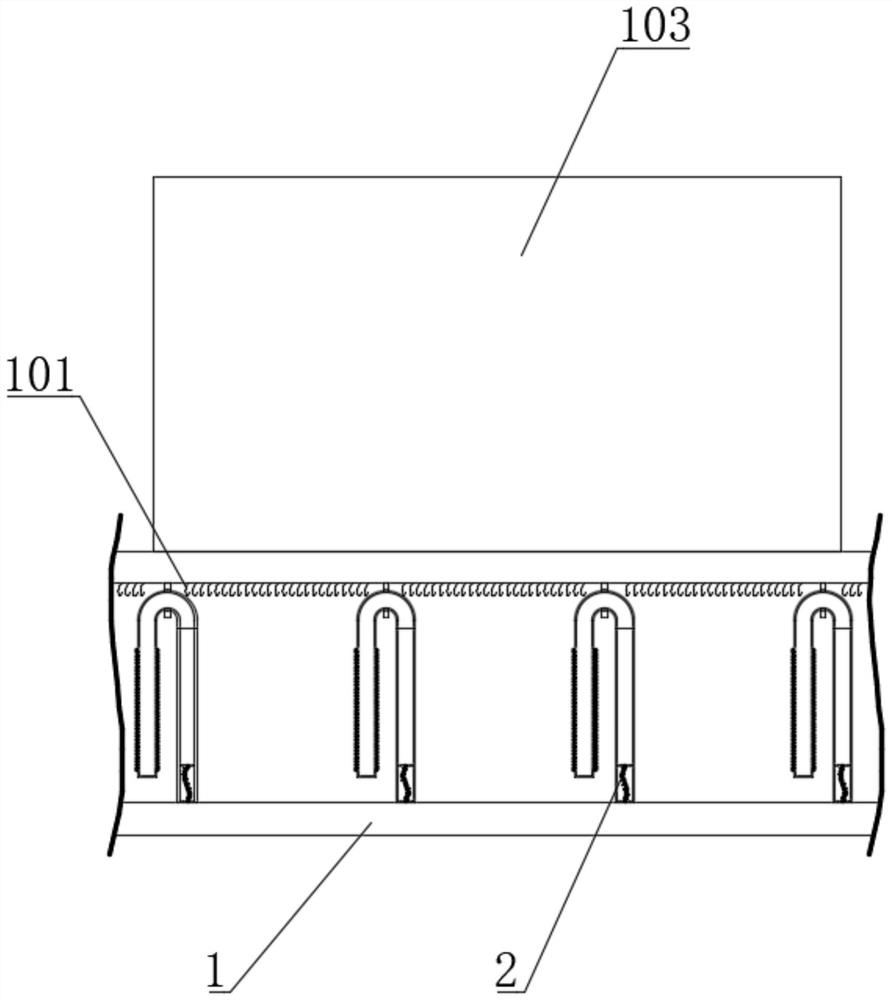

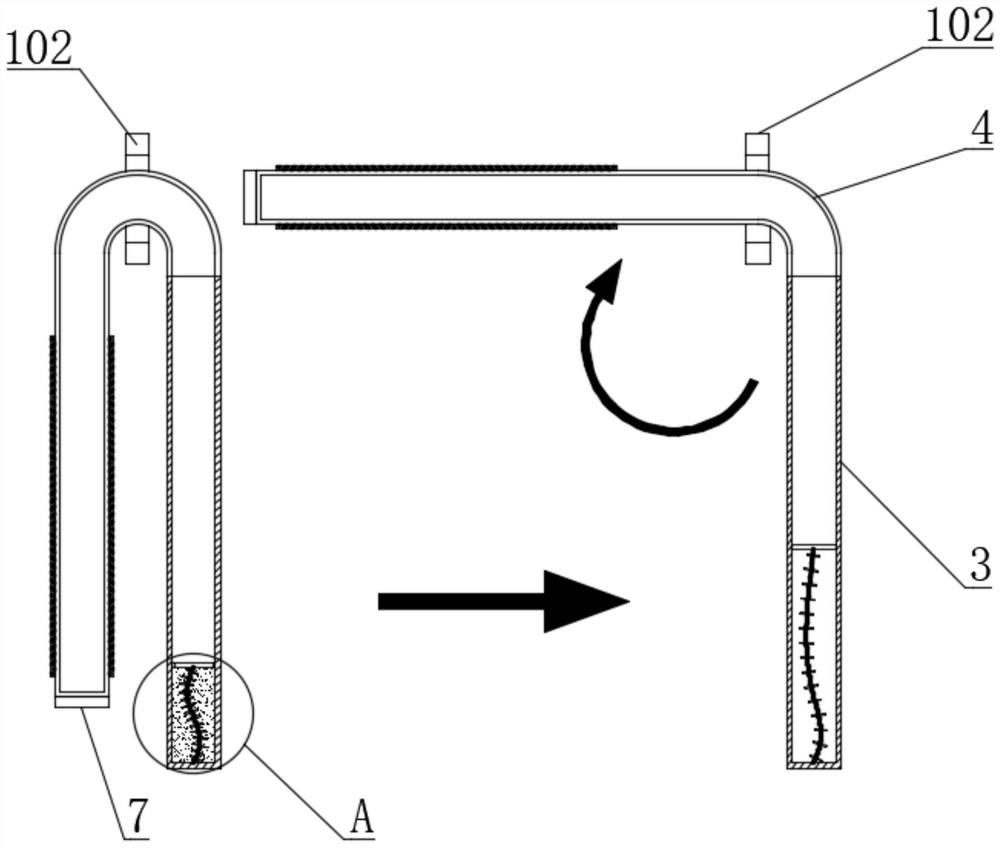

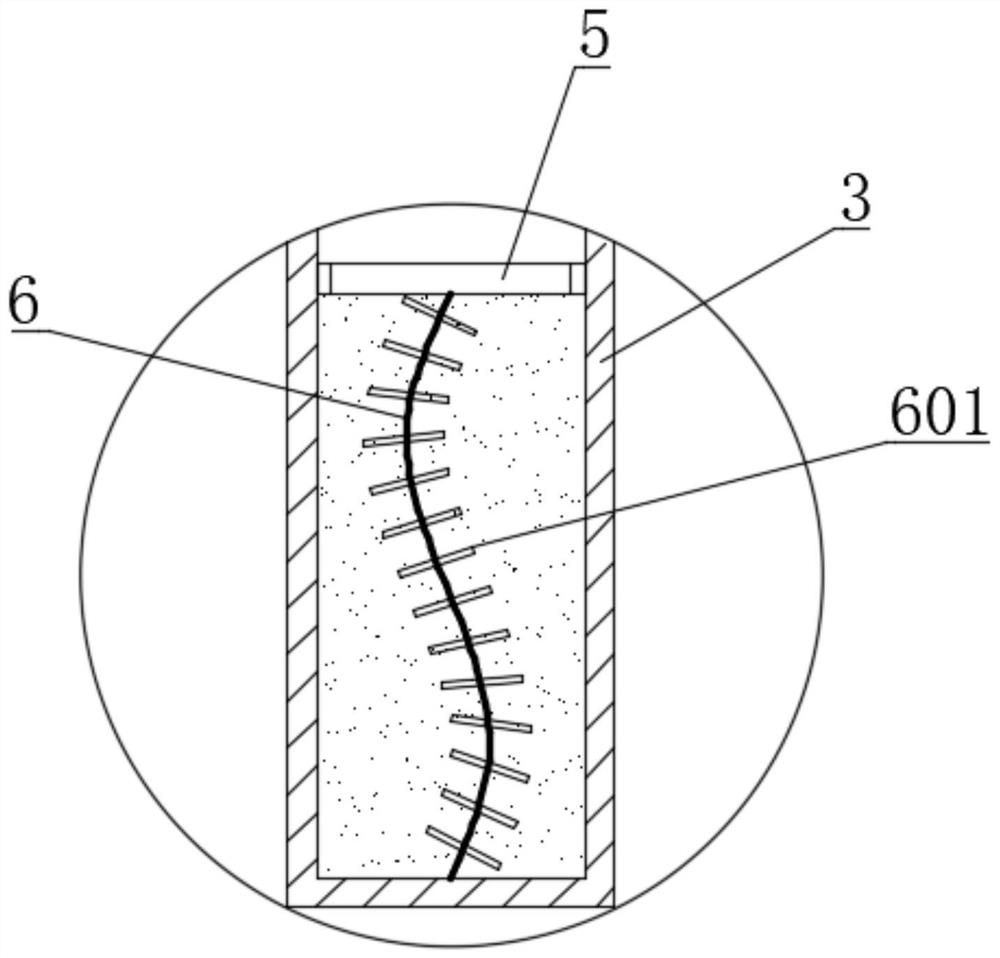

[0044] see Figure 1-5 , a flue gas waste heat collection and discharge pipe for waste combustion, comprising a flue gas transmission pipe 1, the inner wall of the flue gas transmission pipe 1 is fixedly connected with a plurality of evenly distributed heat collection swing pipes 2, and the heat collection swing pipe 2 includes a flue gas transmission pipe 1. The fixed half-pipe 3 is fixedly connected to the inner wall. The upper end of the fixed half-pipe 3 is fixedly connected to the rubber half-pipe 4. The fixed half-pipe 3 and the rubber half-pipe 4 communicate with each other. The plate 5 is fixedly connected with the inner bottom of the fixed half pipe 3 with an elastic connecting rope 6, the bottom end of the rubber half pipe 4 is fixedly connected with a magnetic circular plate 7, and the inner bottom of the piston circular plate 5 is fixedly connected with a magnet block that is mutually repulsive to the magnetic circular plate 7 The upper and lower ends of the rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com