Rapid detection method for shape and position size of part

A detection method and technology for parts, which are applied in measurement devices, instruments, manufacturing computing systems, etc., can solve problems such as being unsuitable for embedded use in mobile terminals, unable to achieve rapid detection of parts and components, and poor ability to recognize complex backgrounds. Deploy, improve detection reliability, overcome the effect of subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

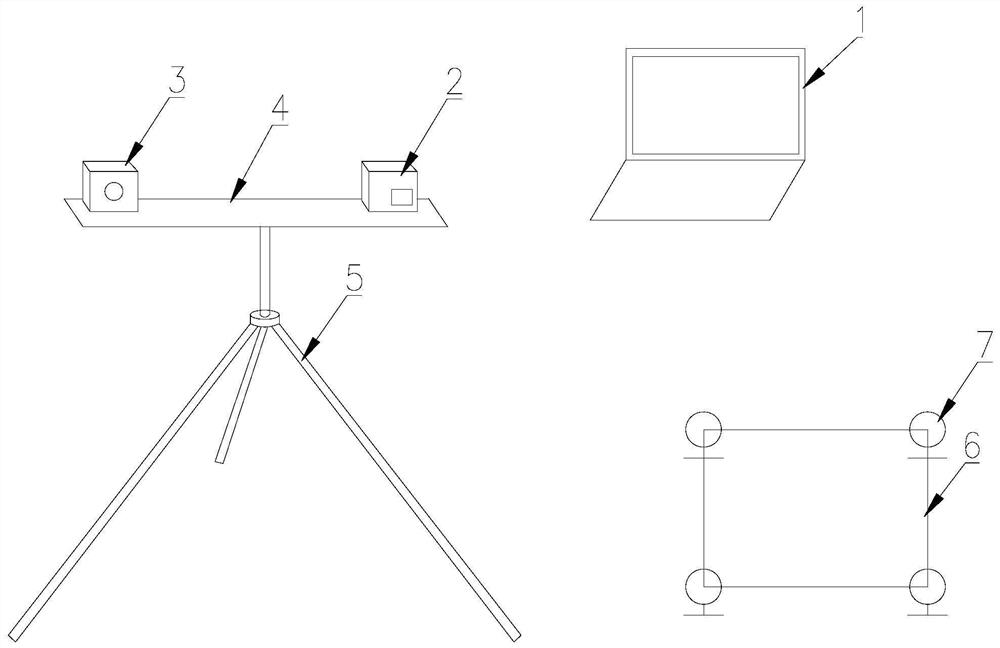

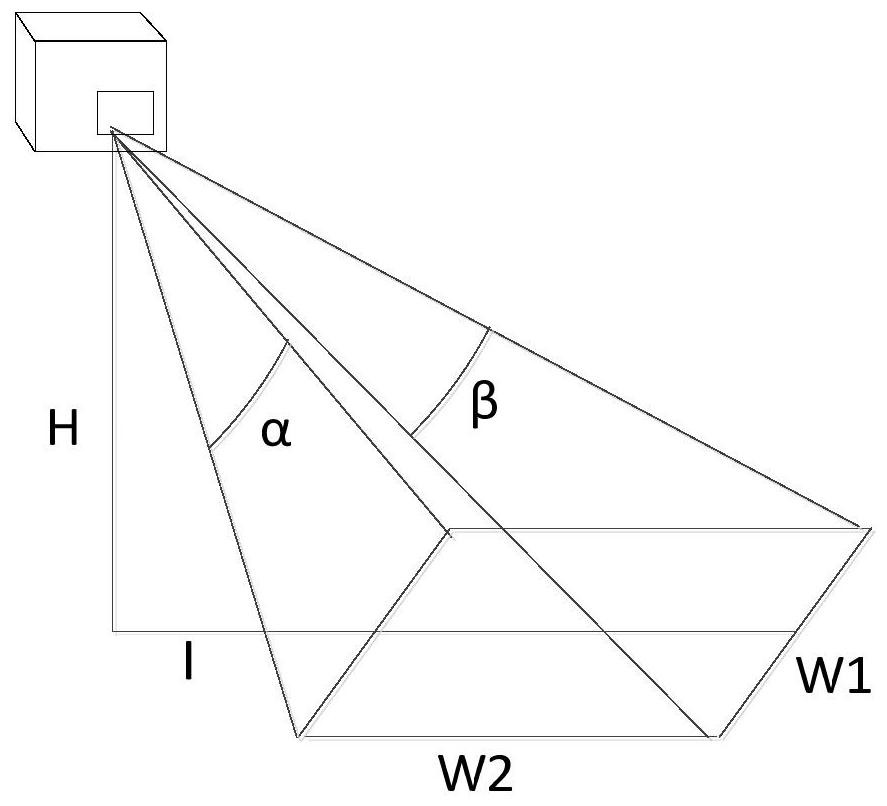

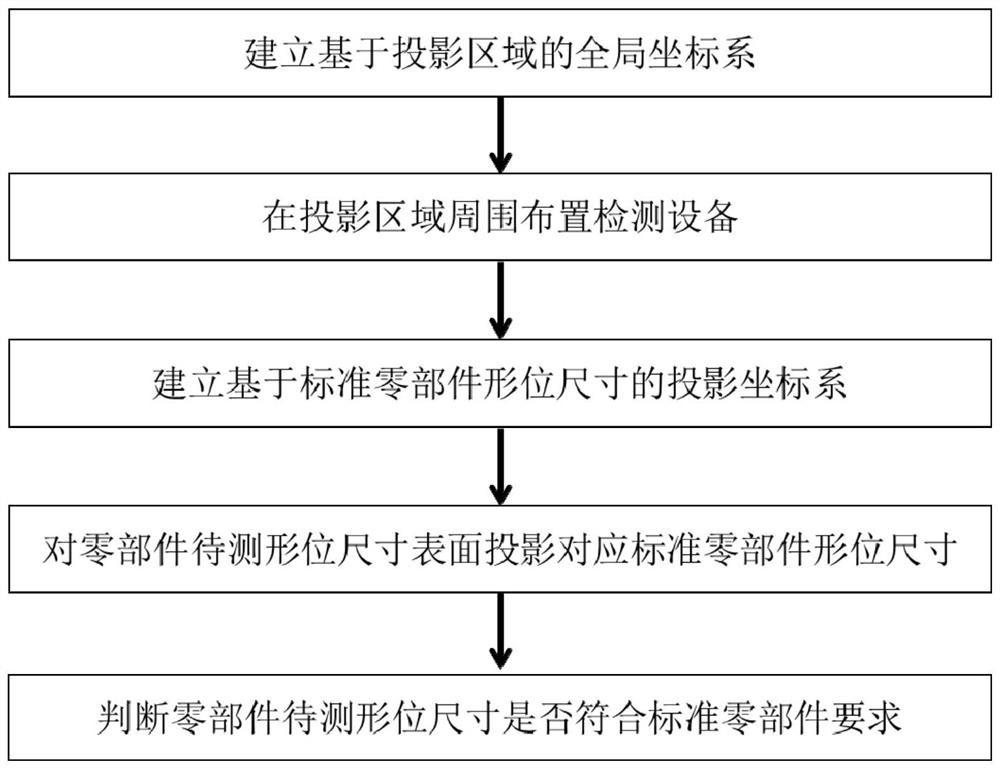

[0059] Such as figure 1 As shown, the present invention provides a rapid detection method for the shape, position and size of parts, and controls the three-dimensional laser projector 2 to project the shape, position and size characteristics of the standard parts obtained from the two-dimensional drawings onto the surface of the parts to be tested, and the visible light camera 3 collects The image is transmitted to the control and processing terminal 1, and it is determined whether the component to be tested meets the requirements of the standard component based on the alignment of the component’s geometric size with the standard component. Using the geometric dimensions of standard parts obtained from the two-dimensional drawings, control the three-dimensional laser projector 2 to display the laser contours of the standard components to the surface of the geometric dimensions of the components to be measured, and quickly pass through whether the geometric dimensions of the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com