An adaptive automatic leveling auxiliary leg control method and system

A technology of automatic leveling and control method, applied in the direction of using feedback control, etc., can solve problems such as auxiliary support legs not working, support legs damage leveling accuracy, etc., to improve debugging efficiency, improve system reliability and stability , the effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

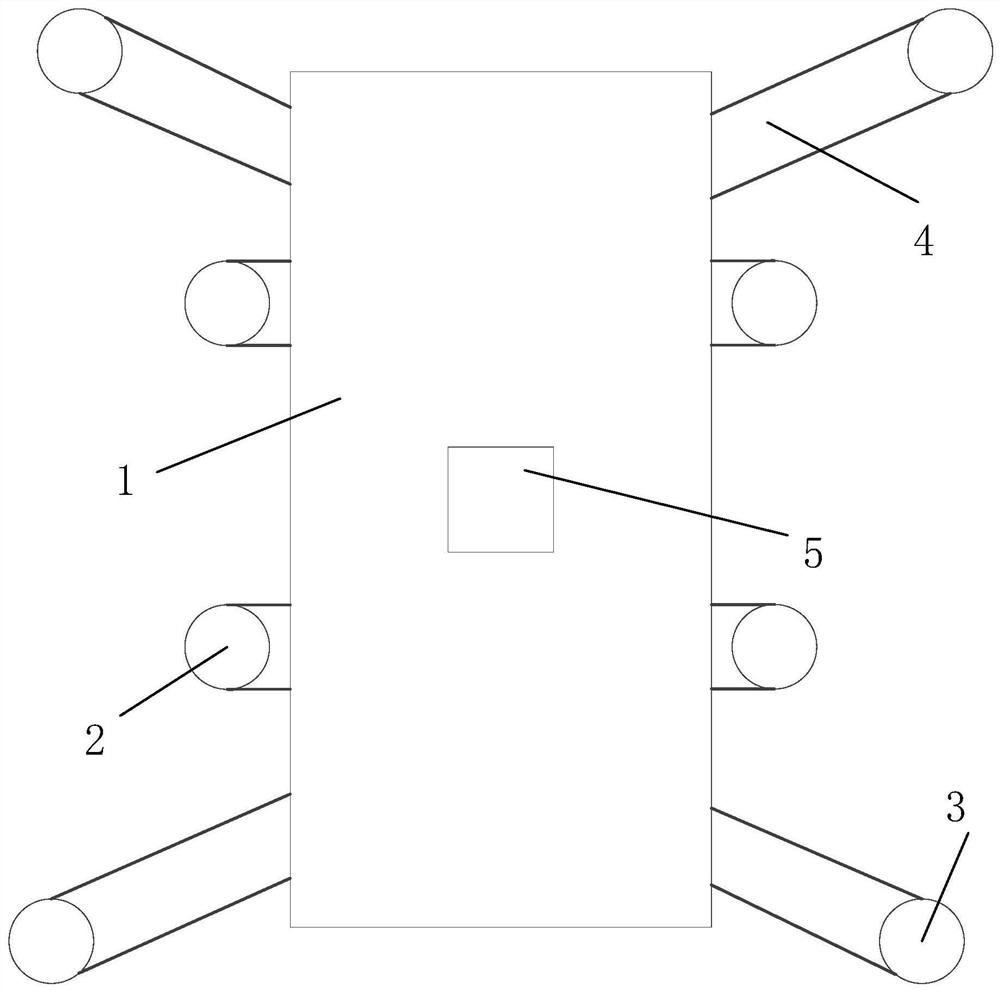

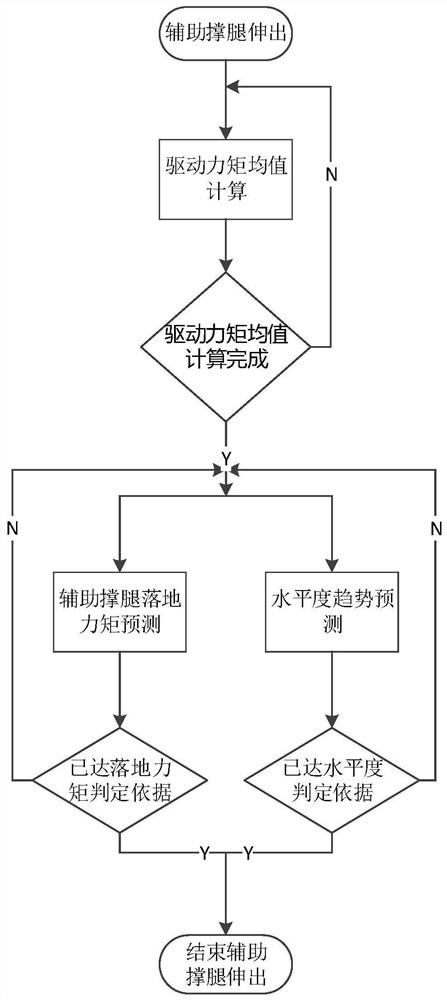

[0044] This embodiment provides a technical solution: an adaptive automatic leveling auxiliary leg control method, including the following steps:

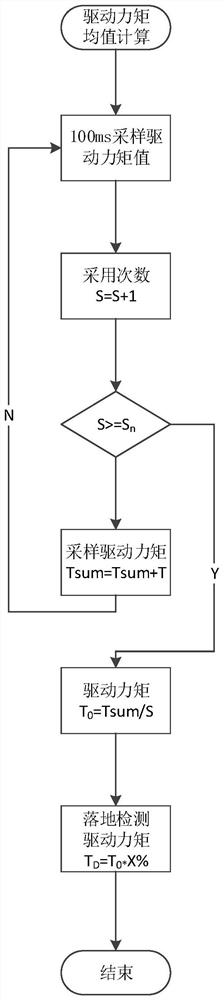

[0045] S1: Calculation of average driving torque

[0046] The auxiliary support leg starts to extend, and the driving torque of the auxiliary support leg is detected in real time, and the average torque value under the current environment and working conditions is calculated, and the current landing torque detection threshold of the auxiliary support leg is determined;

[0047] S2: Prediction of landing moment of auxiliary leg and prediction of horizontality value trend

[0048] During the process of extending the auxiliary support leg to the landing, the current driving torque value of the auxiliary support leg is detected, and the landing torque detection threshold determined in step S1 is used to judge whether the landing torque stop action condition is reached; at the same time, the level value of the carrier platform is collec...

Embodiment 2

[0073] Such as figure 2 As shown, this embodiment provides a technical solution: an adaptive automatic leveling auxiliary leg control method. This method uses software algorithms, comprehensive calculation of the average value of driving torque, prediction of auxiliary leg landing torque, levelness trend prediction and other methods , to realize the automatic landing control of the auxiliary leg. The calculation of the mean value of the comprehensive driving torque solves the problem of the threshold threshold of the driving torque of the auxiliary leg under various environmental conditions; the prediction of the landing moment of the auxiliary leg can accurately judge whether the auxiliary leg is firmly supporting the ground; the levelness trend prediction It is ensured that the original leveling accuracy will not be damaged after the auxiliary leg falls to the ground; the above steps are combined, combined with the software to realize the automatic landing control of the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com