Multi-path parallel ultra-high-speed low-voltage high-current pulse type constant current source

A pulse constant current, ultra-high-speed technology, applied in the power supply field, can solve the problem that the output current only reaches the level of 100 amperes, achieve the effect of fast adjustment speed, ensure consistency, and enhance driving ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

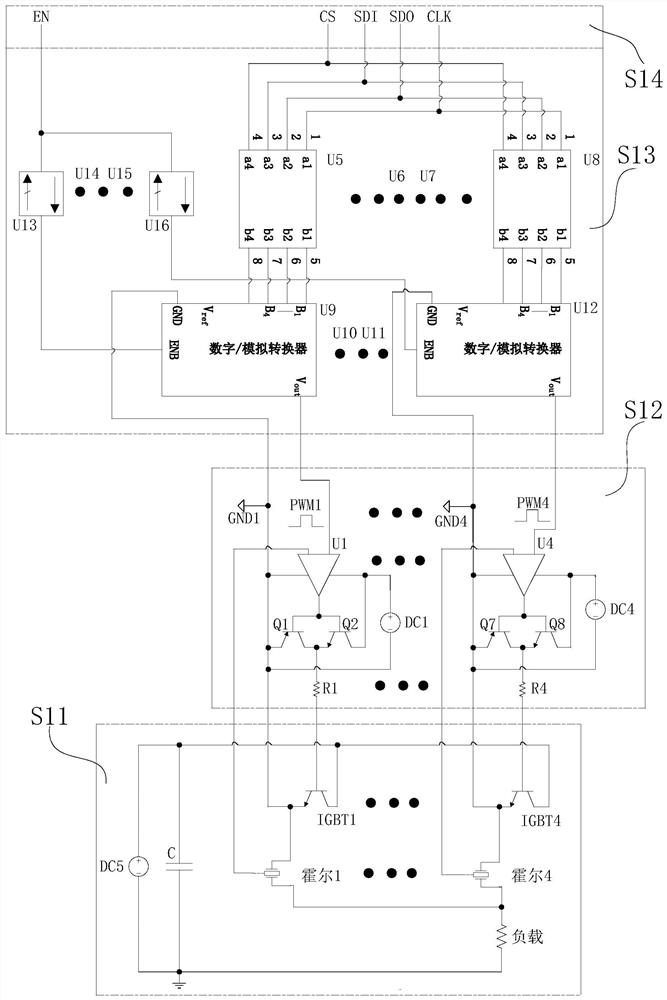

[0034] like figure 1 As shown, a multi-channel parallel ultra-high-speed low-voltage high-current pulsed constant current source includes a main circuit (S11), a pulsed constant current source control circuit (S12), and a pulse signal generating source (S13) circuit; the pulse The signal generation source (S13) circuit is connected to the pulse constant current source control circuit (S12), and is used to send a PWM signal source with adjustable amplitude, pulse width and frequency to the pulse constant current source control circuit (S12) as a given signal ; The multiple outputs of the pulse constant current source control circuit (S12) are respectively connected to a plurality of IGBTs of the main circuit (S11), and the emitter output currents of a plurality of IGBTs of the main circuit (S11) are input to the pulse constant current as a feedback signal In the source control circuit (S12), the given signal is compared with the feedback signal, and the proportional-integral re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com