Unsealing device and method for ceramic cavity glass cover plate structure device

A glass cover plate and device technology, which is applied in semiconductor/solid-state device manufacturing, measuring devices, instruments, etc., can solve the problems of corrosion damage to semiconductor chips, damage to the internal structure of devices, and difficult control, so as to ensure the quality of unsealing and precise control , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

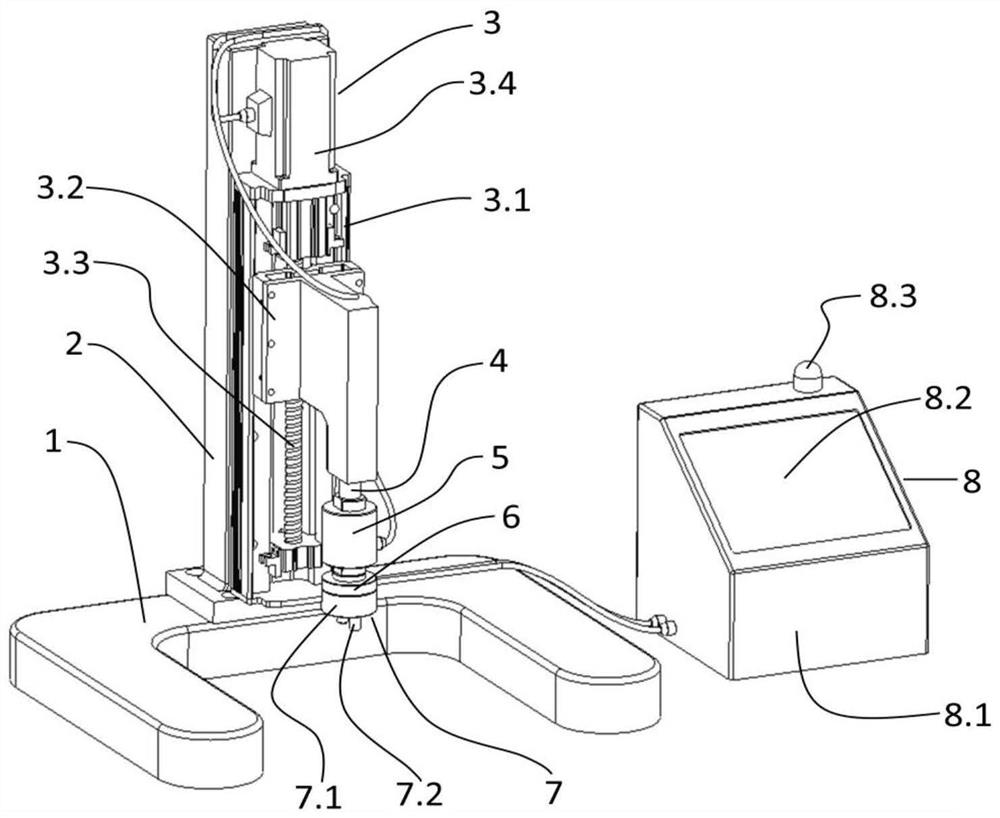

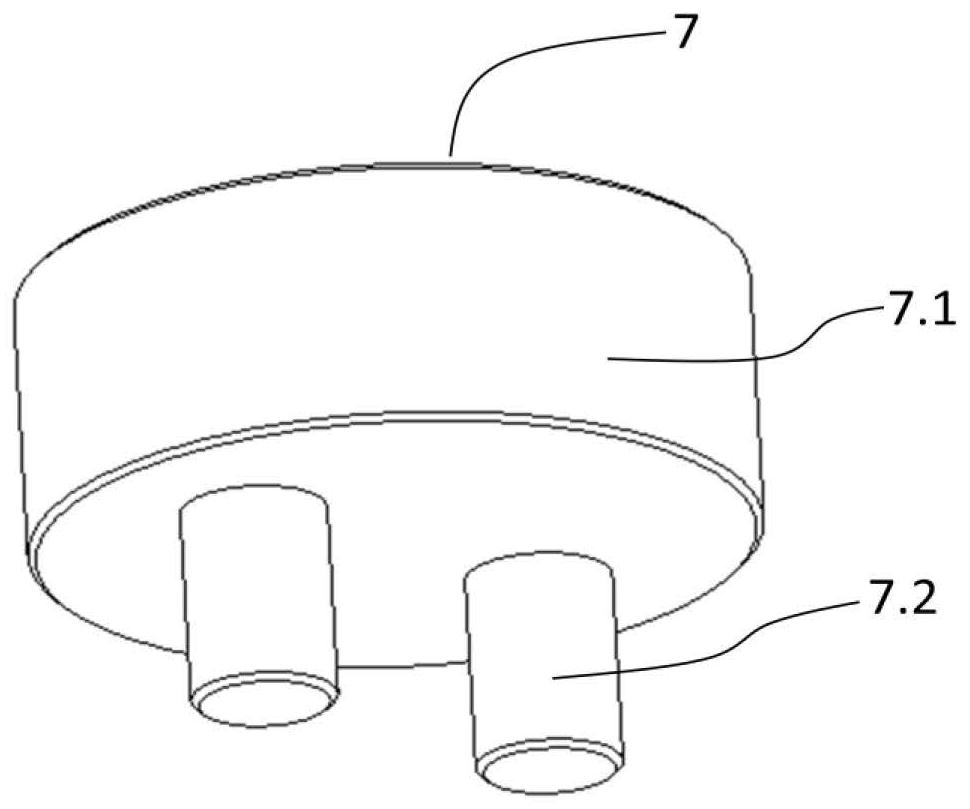

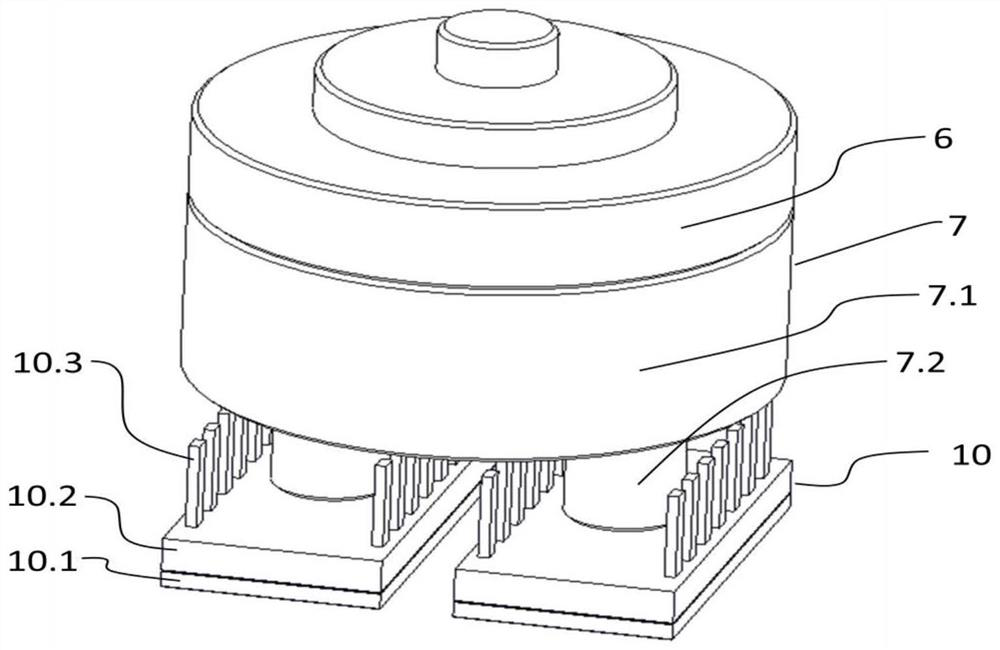

[0031] As shown in the figure, an unsealing device for ceramic cavity glass cover plate structural devices includes a base 1 and a bracket 2 vertically fixed on the base 1, and also includes a linear module 3, a connecting rod 4, a tension sensor 5, Magnet block 6, adapter assembly 7, console 8 and solvent box 9, linear module 3 includes guide rail 3.1, slide block 3.2, screw rod 3.3 and motor 3.4, guide rail 3.1 is fixed on bracket 2, slide block 3.2 is driven by motor 3.4 Driven by the screw rod 3.3 to move or stop along the guide rail 3.1, the slider 3.2 is connected to the upper end of the tension sensor 5 through the connecting rod 4, the lower end surface of the tension sensor 5 is the signal sensing end, and the adapter assembly 7 includes a base plate 7.1 and an adap...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap