Filtering component of tobacco product and tobacco product

A technology for filter components and tobacco products, which is applied in tobacco, smoke oil filter elements, applications, etc., can solve the problem of high flue gas inlet temperature, achieve the effects of reducing flue gas temperature, enhancing material exchange and energy exchange, and reducing inlet temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

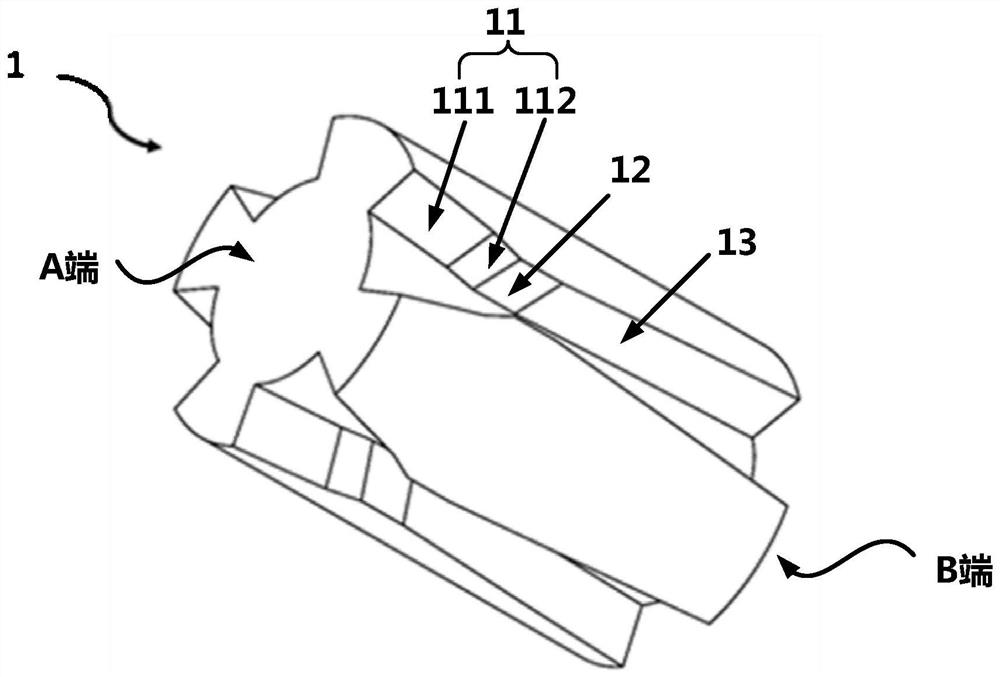

[0029] Please refer to figure 1 , shows a schematic structural view of the filter segment 1 in the filter component of a tobacco product provided by Embodiment 1 of the present invention. It should be noted that in the drawings of this embodiment, unnecessary components are simplified, such as filter components wrapping layer in . However, it is understandable that in figure 1 The outer surface of the shown filter section 1 is covered with a cylindrical wrapping layer, so that at least part of the outer surface of the filter section 1 is closely attached to the inner cavity of the cylindrical wrapping layer, and the Venturi-type filter provided by the application can be formed. Filter components for tobacco products.

[0030] like figure 1 As shown, the outer peripheral surface of the cylindrical filter section 1 is provided with an axially through groove, wherein the groove width of the groove first shrinks and then expands gradually along the preset airflow direction; the...

Embodiment 2

[0046] The present invention also provides a tobacco product, which comprises the above-mentioned filter component and any one or more smoke generating devices.

[0047] In this embodiment, the above-mentioned smoke generating device may be a traditional combustion-type cigarette product, or a new type of heat-not-burn tobacco product or an e-cigarette oil heating device, which is not specifically limited in this application.

[0048] In the tobacco product provided in this application, through the Venturi channel provided on the filter part, after the smoke is injected into the filter part, the Venturi channel guides the smoke forcibly, so that the heat energy of the smoke is further converted The mechanical energy required for gas flow achieves the purpose of active cooling, thereby reducing the temperature of the flue gas flowing out of the air outlet, and improving the taste of consumers. At the same time, because the above-mentioned Venturi channels in this embodiment are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

| Radial depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com