Process for producing filter bag by utilizing melt-blowing method, and filter device

A filter device and filter bag technology, applied in the directions of dispersed particle filtration, separation methods, chemical instruments and methods, etc., can solve the problem of difficult forming of pleated filter bags, increase the air contact area, improve the filtration efficiency and filter effect. significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present invention provides a kind of technology that utilizes meltblown method to produce filter bag, comprises the following steps:

[0042] (1) Feeding: put PP (polypropylene) material and electret masterbatch into feeding device according to a certain ratio;

[0043] (II) Heated extrusion: the raw materials are transported to the extruding device through the feeding device, and the mixed raw materials are extruded and heated through the extruding device, so that the raw materials are melted into a flowable melt, and electric heating is used for heating;

[0044] (III) Filtration: The flowable melt produced by extrusion passes through the filter device to filter impurities and coarse particles;

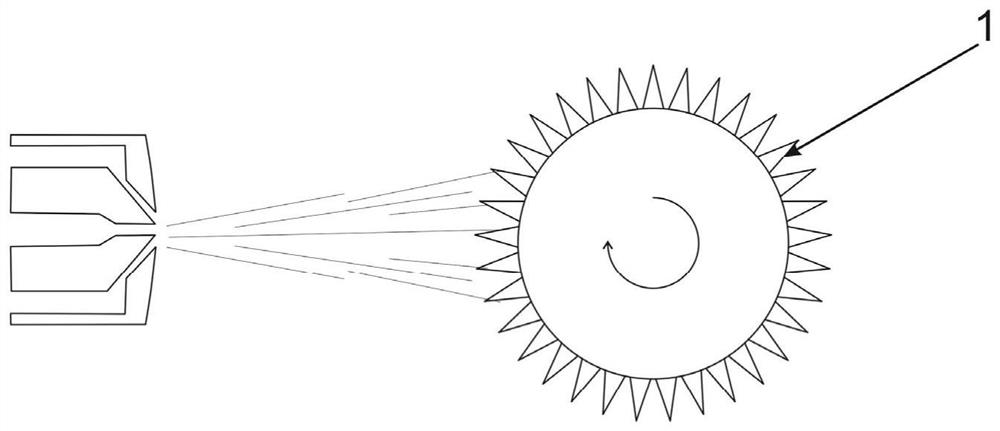

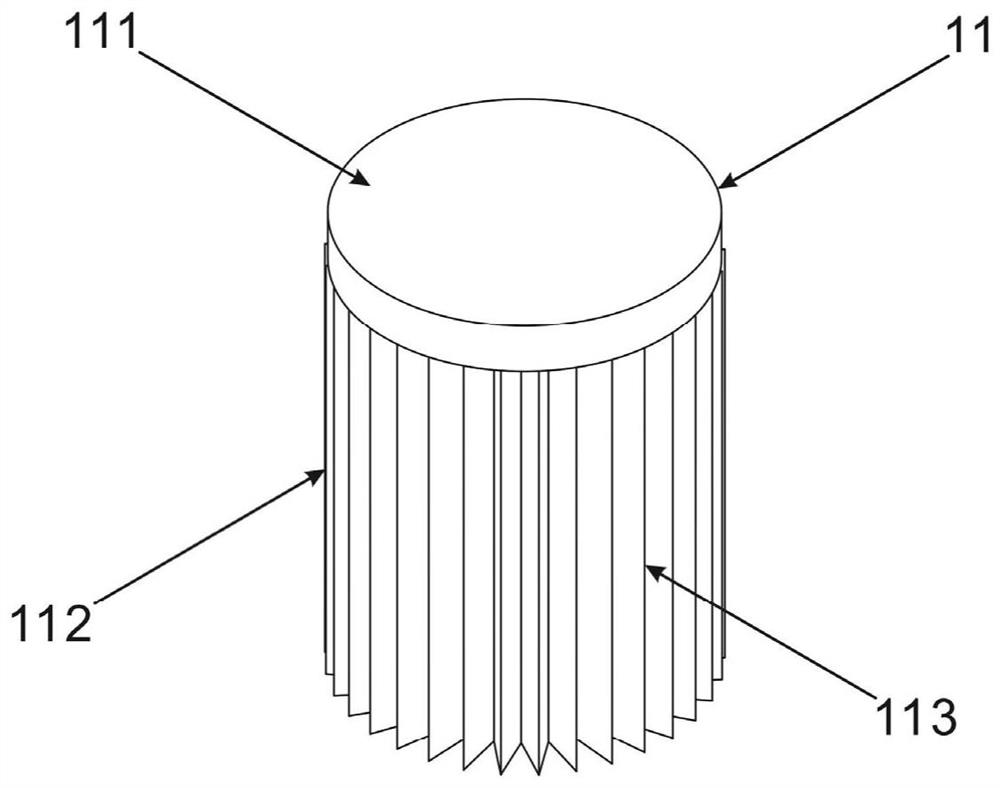

[0045] (IV) Spinning molding: the flowable melt after filtering is ejected through the spinning device and falls to the forming die 1, and the spinning device includes an electric hot air device and a spinneret, etc., such as figure 1 As shown, the high-temperature tract...

Embodiment 2

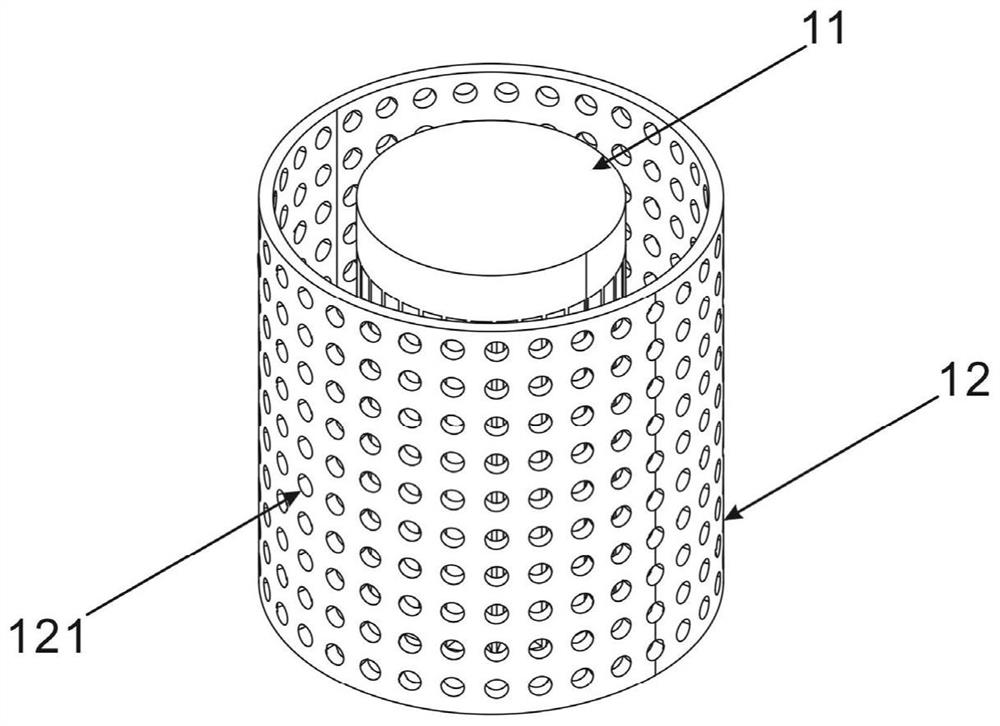

[0059] The difference between embodiment 2 and embodiment 1 is that, as image 3 As shown, the forming mold 1 also includes a high temperature mold 12, the high temperature mold 12 is set on the outside of the normal temperature mold 11, the high temperature mold 12 is set as a barrel structure with one end open, the normal temperature mold 11 is arranged in the high temperature mold 12 and is connected with the high temperature mold 12 A barrel-shaped clamping cavity is formed between the inner walls, and the bottom wall and the side wall of the high-temperature mold 12 are densely covered with spinneret holes 121, and the spinneret holes 121 communicate with the clamping cavity;

[0060] In the process of step (IV) spinning, the flowable melt is sprayed onto the normal temperature mold 11 through the spinning hole 121 , and cooled on the normal temperature mold 11 to form a filter bag with an open top.

[0061] During this process, the temperature of the high-temperature mol...

Embodiment 3

[0065] The difference between embodiment 3 and embodiment 1 is that the axial dimension of the normal temperature mold 11 is longer, and in the process of step (IV) spinning, the top wall and the bottom wall of the normal temperature mold 11 are not sprayed, and the spinning molding After completion, the resulting filter bag is open at both ends and has a cylindrical shape.

[0066] After the step demoulding (VI) is completed, the cylindrical filter bag is cut.

[0067] After the cutting is completed, the opening position of one end of the cut filter bag is sealed to obtain a melt-blown filter bag 2 with one end open.

[0068] This implementation mode does not need the sealing step, although compared with Example 1 and Example 2, the cutting and capping steps have been added, but in the process of actual production, it is not necessary to spray the sealant as in Example 1 and Example 2. The silk device starts and stops intermittently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com