Free forging forming process and die for large bent knife plate forgings

A forming process and forming die technology, applied in the field of forging, can solve the problems affecting service performance, the shape of the machete is difficult to form, and the flow line of the parts is discontinuous, etc., so as to improve the utilization rate of materials, reduce the forging process, and improve the quality of forgings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of non-equal thickness preform is only a preform preparation method proposed by the present invention for the production of large machete plate forgings, and does not limit the present invention. The method of free forging and final forging of large-scale machete plate forgings described later in the invention and the manufacturing method of forging and forming machete plate forgings with molds all fall within the scope of protection of the present invention.

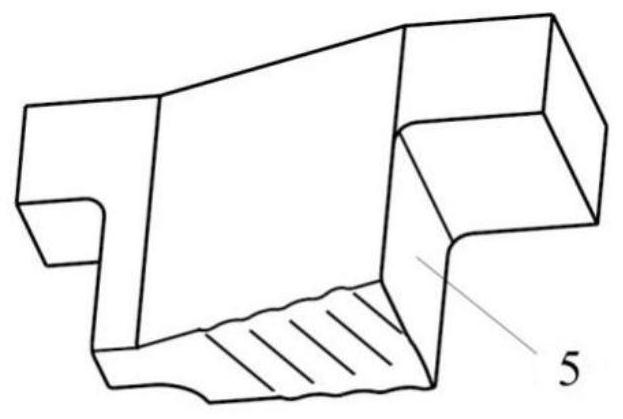

[0032] The preforms with unequal thickness on both sides are heated to the initial forging temperature, kept warm and evenly heated, and sent to the free forging final forging drawing die. Use the free forging final forging and drawing die with upper and lower anvils with diversion grooves and asymmetric baffles on both sides of the lower die for multi-step forging and drawing. After each feeding and pressing, only the upper and lower anvils The material area between them is deformed. After...

Embodiment 1

[0038] In order to illustrate the technical process of the present invention more clearly, the implementation process of the present invention will be further described in detail by taking the free forging process of the large machete plate support as an example. The forging process is divided into the following steps:

[0039] step 1:

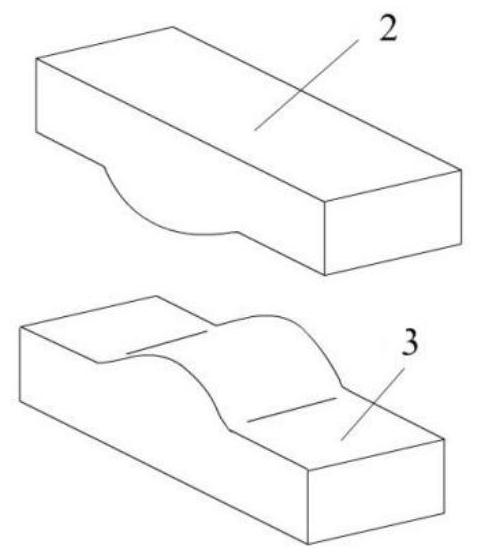

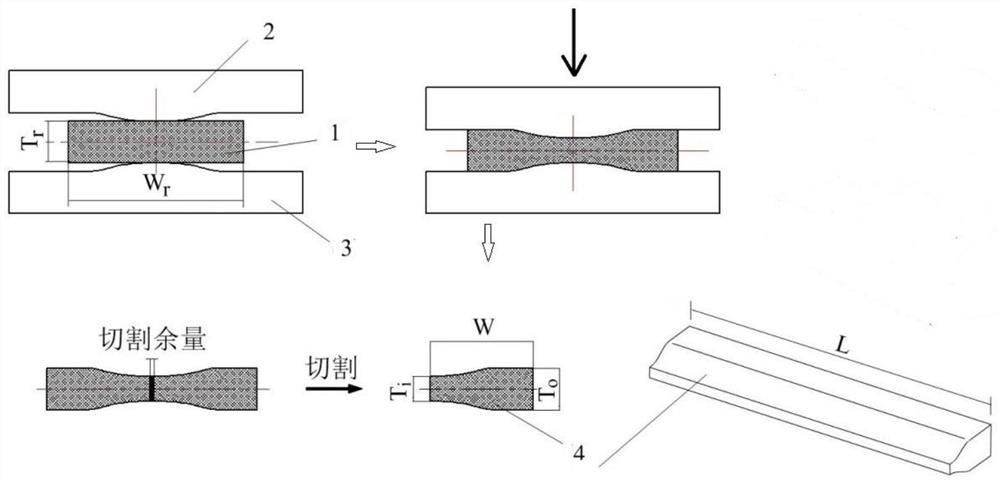

[0040] Design forming mold and preform size: such as figure 1 , 2 , 3 and 4, the forming dies are divided into free forging preform dies and free forging final forging drawing dies. Determine the size of the hot forging of the machete plate according to the shape and size of the part, the machining allowance and the thermal expansion rate of the material. According to the shape of the hot forging of the scimitar plate, determine its thickness T and width W 0 And the radius of curvature R of the centerline. Preform width W and hot forging width W 0 same. Preform Thin Side Thickness T i It is the same as the thickness T of the hot forgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com