Preparation method of high-melting-point Kelvin structure lattice metal based on laser additive manufacturing

A high melting point metal, laser additive technology, applied in the direction of additive processing, etc., can solve the problems of complex investment casting process, thick hole and edge diameter, etc., and achieve the effect of overcoming the defects of anisotropic mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment is to design and prepare a high melting point Kelvin structure lattice metal with a porosity of 43% and 316L stainless steel as a matrix;

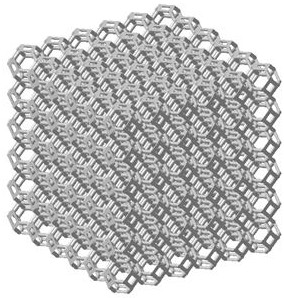

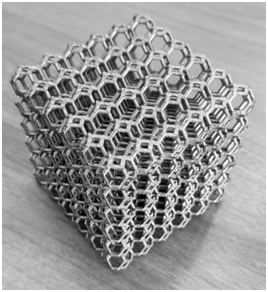

[0032] Such as figure 1 As shown, it is the design model of the Kelvin structure lattice metal unit. The Kelvin structure lattice metal unit adopts the three-dimensional design software to carry out the adaptive design of the selective laser melting process. The prism diameter is 0.3mm, the prism length is 0.33mm, and the prism length is 0.3mm. Diameter ratio is 1.1, Kelvin structure lattice metal 3D design model, such as figure 2 As shown, the outer contour size of the high melting point Kelvin structure lattice metal design model is 6.5×3.7×3.7 mm, and the porosity is 43%.

[0033] The Kelvin structure lattice metal with 316L stainless steel as the matrix is prepared by selective laser melting process, including the following steps:

[0034] Step 1. Based on the process characteristics of selective laser melti...

Embodiment 2

[0042] This embodiment is to design and prepare a high melting point Kelvin structure lattice metal with a porosity of 71% based on 316L stainless steel;

[0043] Such as figure 1 As shown, it is the design model of the Kelvin structure lattice metal unit. The Kelvin structure lattice metal unit adopts the three-dimensional design software to carry out the adaptive design of the selective laser melting process. The diameter of the prism is 0.8mm, the length of the prism is 1.2mm, and the length of the prism is Diameter ratio is 1.5, Kelvin structure lattice metal 3D design model, such as figure 2 As shown, the outer contour size of the high melting point Kelvin structure lattice metal design model is 23.8×13.6×13.6 mm, and the porosity is 71%.

[0044] The Kelvin structure lattice metal with 316L stainless steel as the matrix is prepared by selective laser melting process, including the following steps:

[0045] Step 1. Based on the process characteristics of selective la...

Embodiment 3

[0052] This embodiment is to design and prepare a high melting point Kelvin structure lattice metal based on the GH4169 superalloy with a porosity of 82%;

[0053] Such as figure 1 As shown, it is the design model of the Kelvin structure lattice metal unit. The Kelvin structure lattice metal unit adopts three-dimensional design software to carry out the adaptive design of the selective laser melting process. The diameter of the prism is 1.2mm, the length of the prism is 2.4mm, and the length of the prism is Diameter ratio is 2.0, Kelvin structure lattice metal 3D design model, such as figure 2 As shown, the outer contour size of the high melting point Kelvin structure lattice metal design model is 47.5×27.1×27.1 mm, and the porosity is 82%.

[0054] Preparation of GH4169 superalloy as matrix Kelvin structure lattice metal by selective laser melting process, including the following steps:

[0055] Step 1. Based on the process characteristics of selective laser melting, the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com