Oil-removing and slag-skimming device for sewage treatment

A sewage treatment and sewage pool technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, multi-stage water treatment, etc. The effect of simple environment and overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

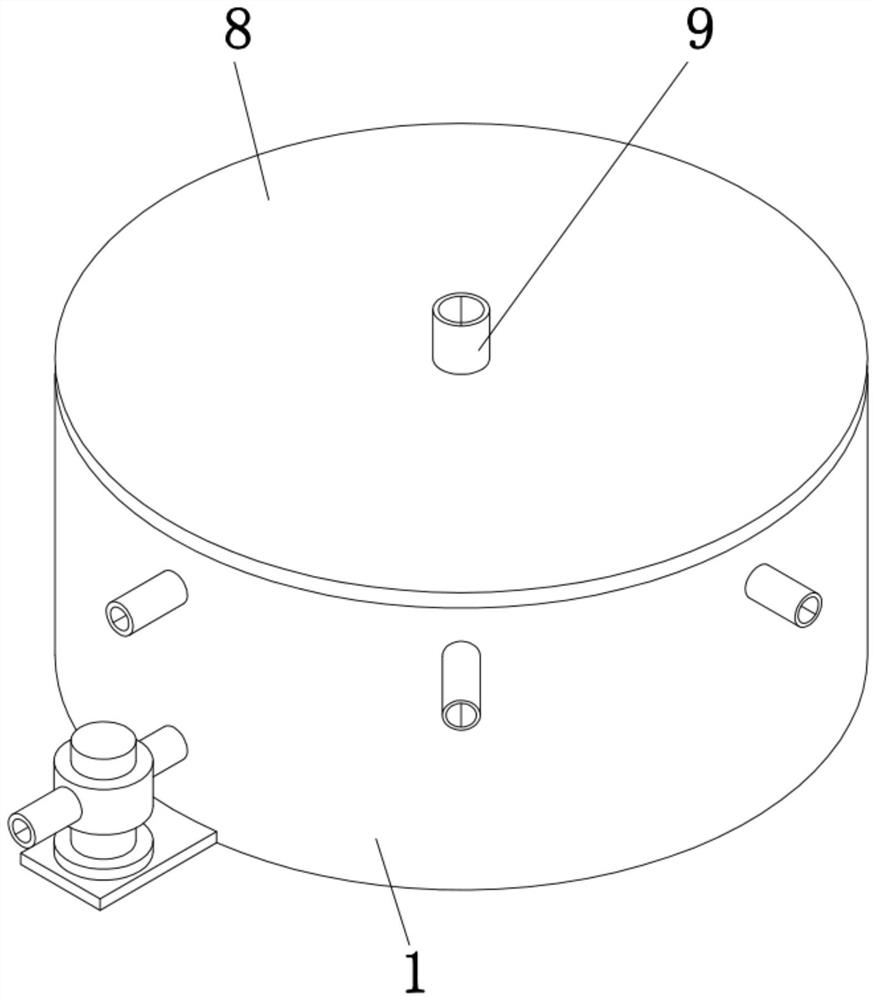

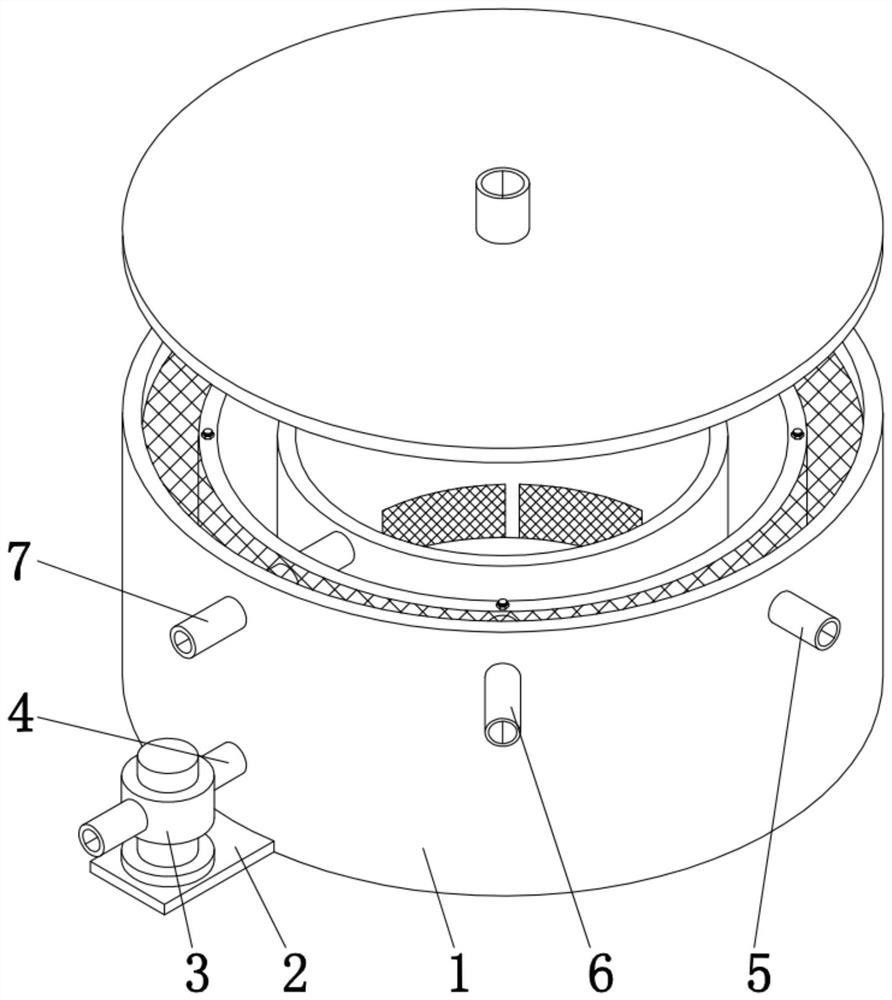

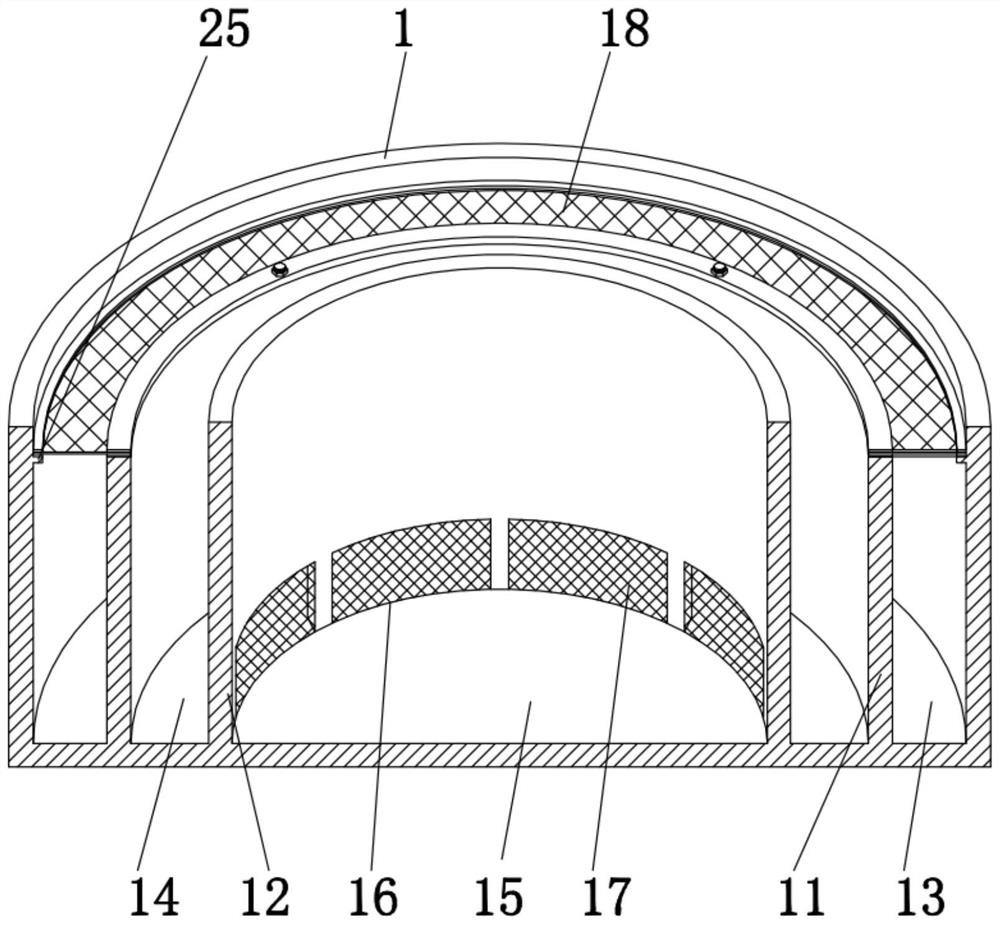

[0038]A device for removing oil and scum for sewage treatment, comprising a sewage pool 1, the bottom inner wall of the sewage pool 1 is welded with a first partition 11 and a second partition 12 distributed in a horizontal structure, and the height of the first partition 11 is low In the second partition 12, waste oil is prevented from flowing into the inside of the drainage chamber 15, and the first partition 11 is located between the side inner wall of the sewage pool 1 and the side outer wall of the second partition 12, the side inner wall of the sewage pool 1, the sewage pool 1 Between the bottom inner wall of the bottom inner wall and the side outer wall of the first partition 11, there is a settling chamber 13, which is used to settle the residue. An oil filter chamber 14 is surrounded between the outer walls for draining waste oil, and a drainage chamber 15 is surrounded between the bottom inner wall of the sewage tank 1 and the side inner walls of the second partition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com