System and method for preparing high-calorific-value synthesis gas through calcium-based chemical-looping gasification of carbon-containing fuel

A high calorific value, synthesis gas technology, applied in the fuel, gas fuel, petroleum industry, etc., can solve the problems of calcium-based adsorbent wear loss, high system investment cost, and high difficulty in controlling the fluidized state of the double bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and examples are only used to explain the present invention, and are not intended to limit the scope of the present invention.

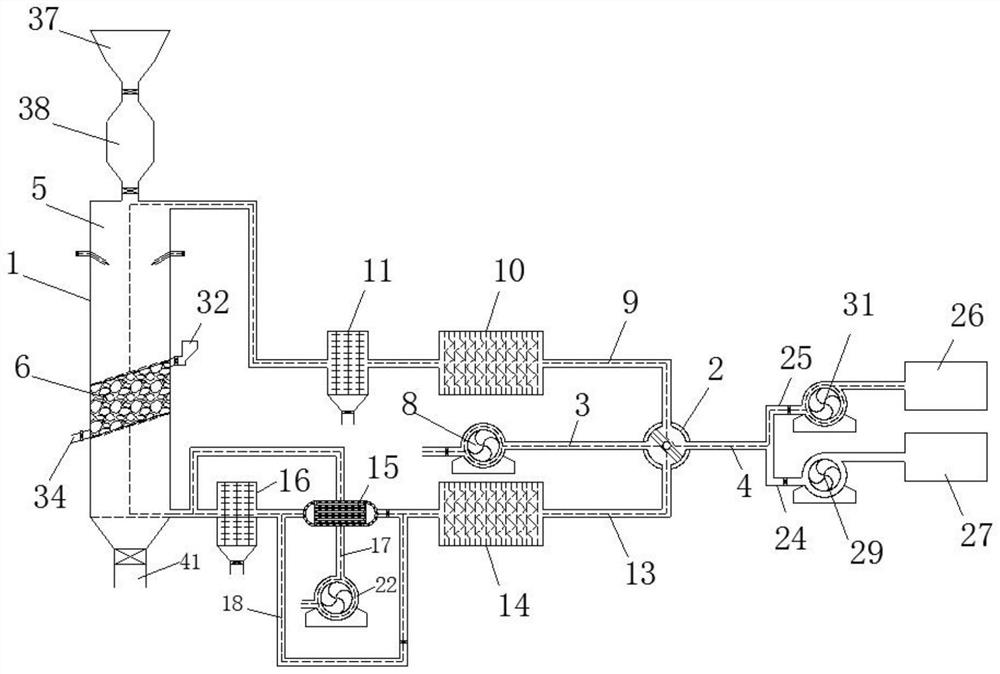

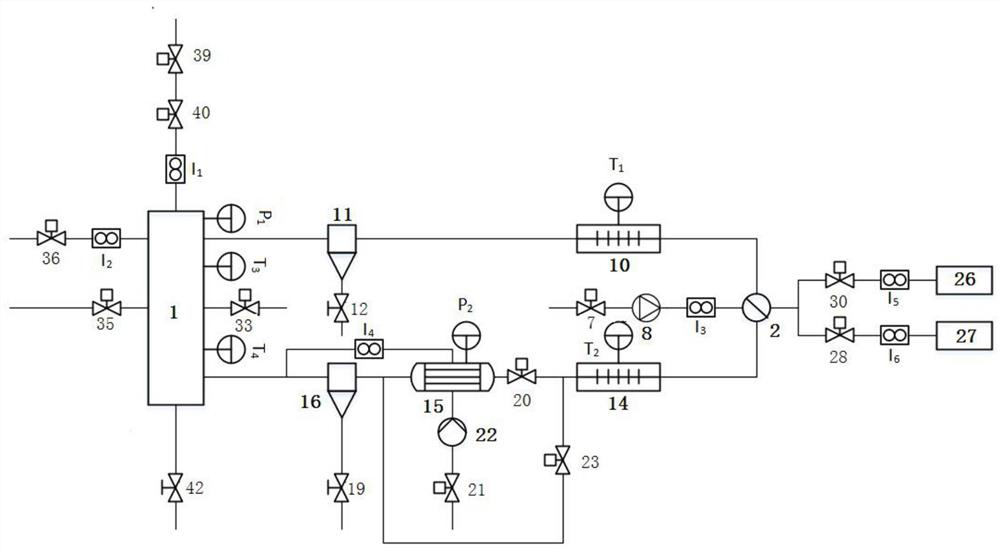

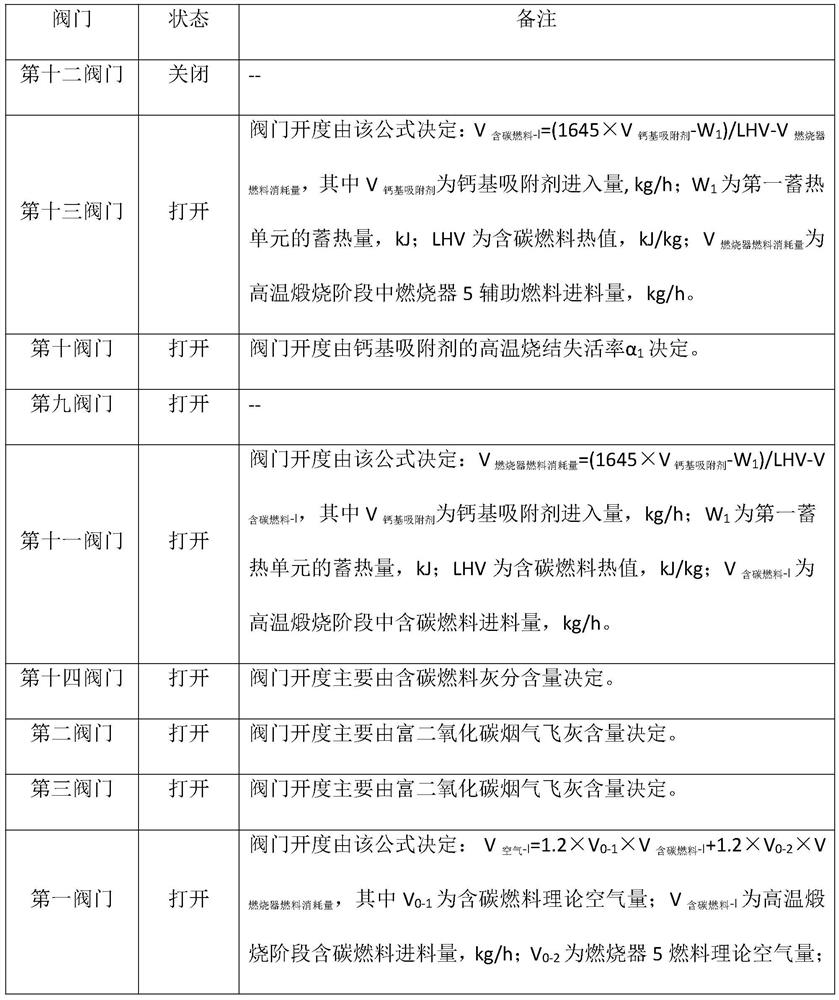

[0047] Such as figure 1 and 2 As shown, a system for preparing high calorific value synthesis gas by calcium-based chemical looping gasification of carbon-containing fuels includes a reactor 1, a combustion device, a gasification device, a reversing valve 2, an inlet pipe 3 and an output pipe 4. The outer wall of the reactor 1 is provided with a first interface and a second interface up and down, a burner 5 is arranged on its inner top, and a calcium-based adsorbent bed 6 is arranged in the middle. One end of the combustion device is connected to the first joint of the reversing valve 2, and the other end is connected to one of the first port or the second port, and provides hot air or hot oxygen to the burner 5 , and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com