Production method of soluble paper

A production method and technology of concentration, applied in the field of papermaking, can solve the problem of high cost, and achieve the effects of reducing waste, improving hand feeling, and improving water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

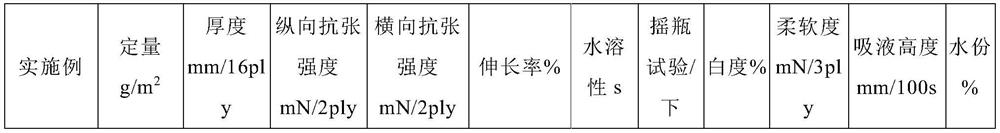

Examples

Embodiment 1

[0028] A production method of soluble toilet paper, the method comprises the following process steps:

[0029] (1) Transition production of toilet paper without humidifying agent for 8 hours;

[0030] (2) Put 6 packs of North American softwood pulp (220 kg dry weight per pack) and 6 packs of Brazilian hardwood pulp (250 kg dry weight per pack) into long and short fiber pulpers respectively, add water to a concentration of about 5.3 wt % and then crushed separately, the crushing time is about 12 minutes, and then pumped into the long and short fiber pulp pool respectively;

[0031] (3) North American coniferous wood pulp is added to the pulp tank before the long fiber pulp to adjust the concentration to about 4.6wt% and passes through the refiner. By controlling the energy consumption of refining to 85kwh / t, the fiber is cut and divided into filaments and then enters the long fiber pulp back pulp pool;

[0032] (4) Brazilian hardwood pulp is added with water from the pulp tan...

Embodiment 2

[0038] A production method of soluble toilet paper, the method comprises the following process steps:

[0039] (1) Transition production of toilet paper varieties without humidifying agent for 10 hours;

[0040] (2) Put 6 packs of North American softwood pulp (220 kg dry weight per pack) and 6 packs of Brazilian hardwood pulp (250 kg dry weight per pack) into long and short fiber pulpers respectively, add water to a concentration of about 6.0 wt % and then crushed separately, the crushing time is about 10 minutes, and then pumped into the long and short fiber pulp pool respectively;

[0041] (3) North American coniferous wood pulp is added water from the pulp tank before the long fiber tap to adjust the concentration to about 4.9wt% and passes through the refiner. By controlling the energy consumption of refining to 90kwh / t, the fiber is cut and divided into filaments and then enters the long fiber tap back pulp pool;

[0042] (4) Brazilian hardwood pulp is added water from ...

Embodiment 3

[0048] A production method of soluble toilet paper, the method comprises the following process steps:

[0049] (1) Transition production of non-embossed toilet paper without humidifying agent for 9 hours;

[0050] (2) Put 6 packs of North American softwood pulp (220 kg dry weight per pack) and 6 packs of Brazilian hardwood pulp (250 kg dry weight per pack) into long and short fiber pulpers respectively, and add water to a concentration of about 6.5 wt. % and then crushed separately, the crushing time is about 10 minutes, and then pumped into the long and short fiber pulp pool respectively;

[0051] (3) North American coniferous wood pulp is added to the pulp tank before the long fiber pulp to adjust the concentration to about 4.1wt% and passes through the refiner. By controlling the energy consumption of refining to 90kwh / t, the fiber is cut and divided into filaments and then enters the long fiber pulp back pulp pool;

[0052] (4) Brazilian hardwood pulp is added with water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com