Semiconductor packaging equipment

A technology for packaging equipment and semiconductors, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc. It can solve the problems of lack of semiconductor mounting positioning height, single method of adjusting wafer clamps, and high equipment cost, and achieve convenient positioning height, improve Safety and improved functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

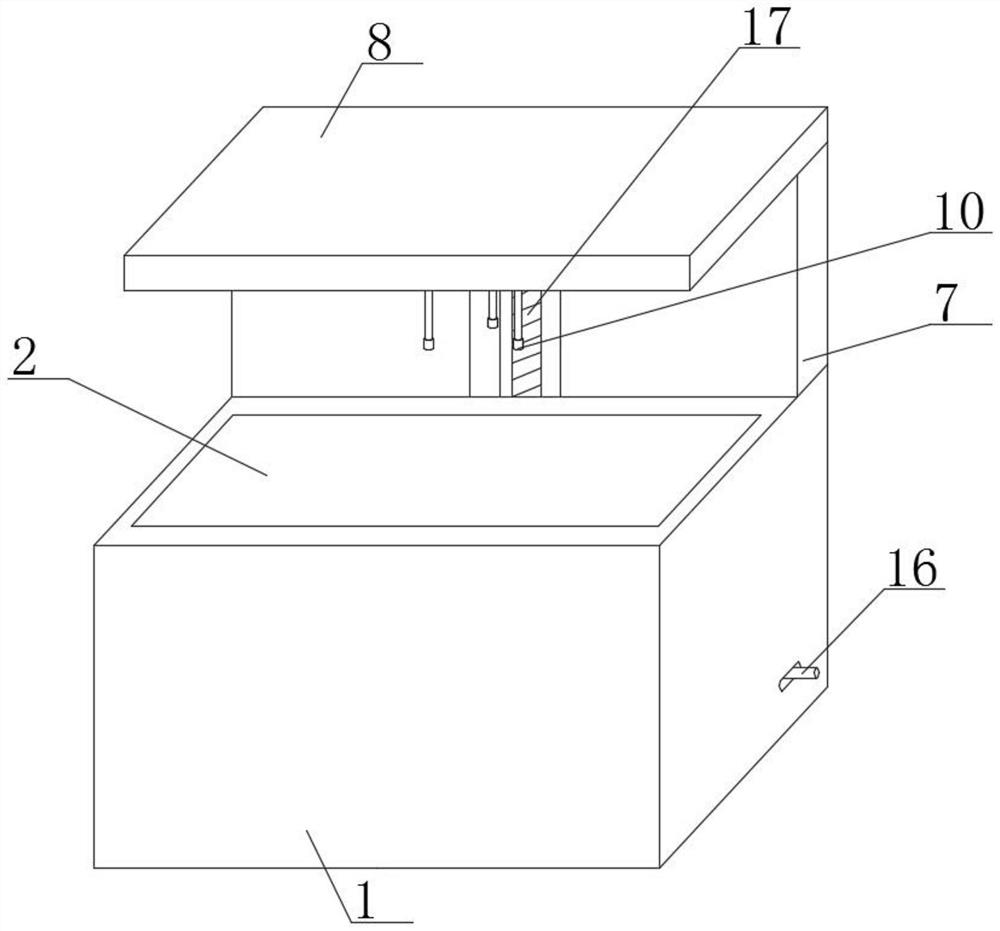

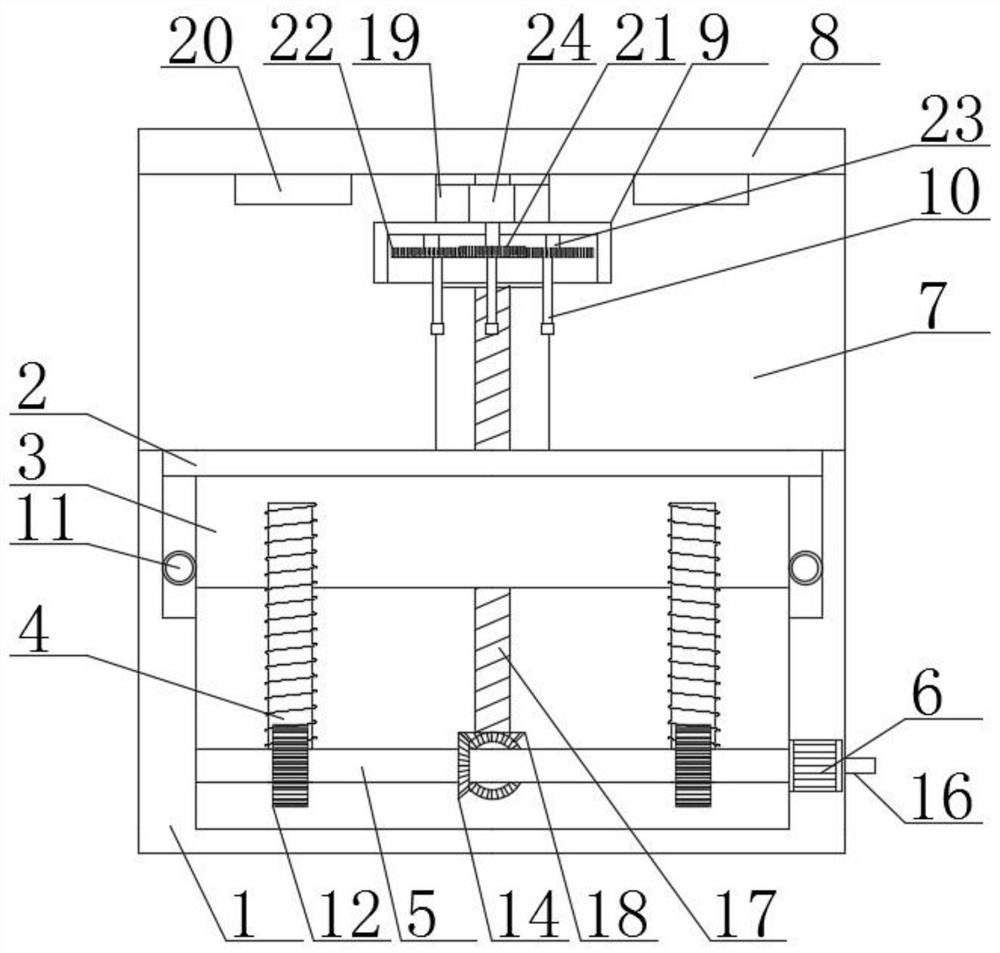

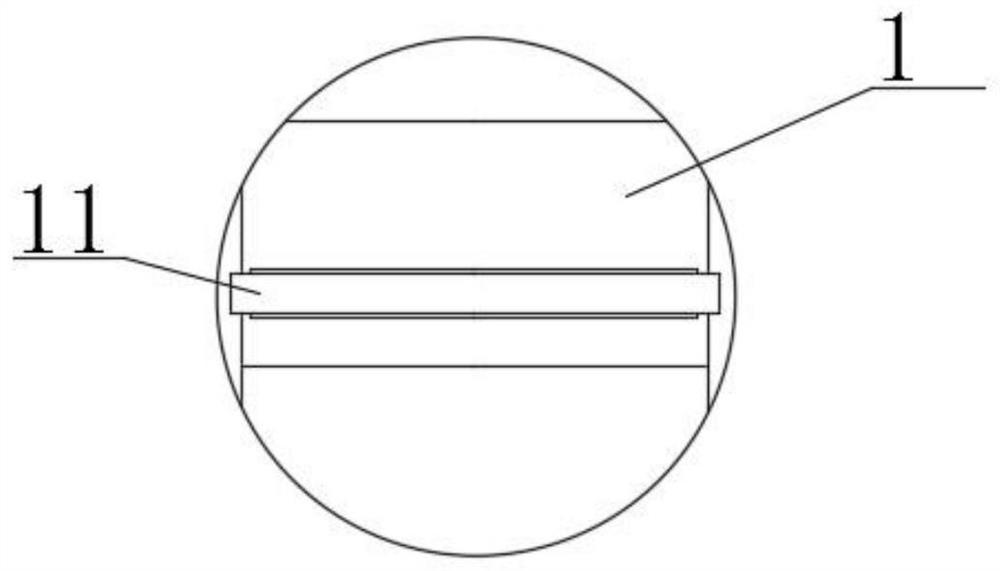

[0027] Such as Figure 1-4 As shown, a semiconductor packaging device includes a base 1, the top outer surface of the base 1 is provided with a placement plate 2, the bottom of the placement plate 2 and the inside of the base 1 are provided with a substrate 3, and the two sides of the bottom of the substrate 3 are located on the base 1 is provided with an adjustment rod 4, the outer side of the adjustment rod 4 and between the two sides inside the base 1 is provided with a rotating rod 5, the right side of the rotating rod 5 and the right side of the base 1 is provided with a motor 6, the motor 6 Y160M1-2 type asynchronous motor can be used, the power is 11kW, the outer surface of the base 1 is provided with a support plate 7, the top outer surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com