Heat dissipation device of heating and ventilation compressor frequency converter

A heat dissipation device and compressor technology, applied in the direction of cooling/ventilation/heating transformation, modification of power electronics, chemical instruments and methods, etc., can solve the problem of reducing the heat dissipation effect of heat sinks, increasing the workload of operators, and inconvenient heat sinks Dismantling and replacing problems to achieve the effect of improving heat dissipation, preventing dust from falling randomly, and improving fixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

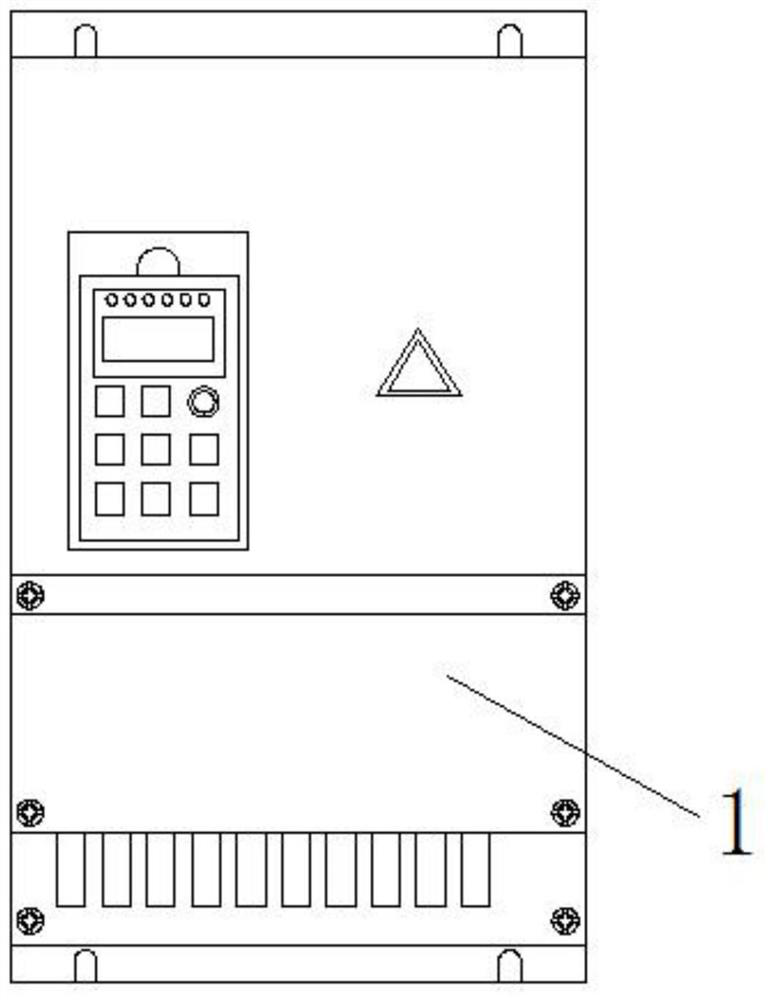

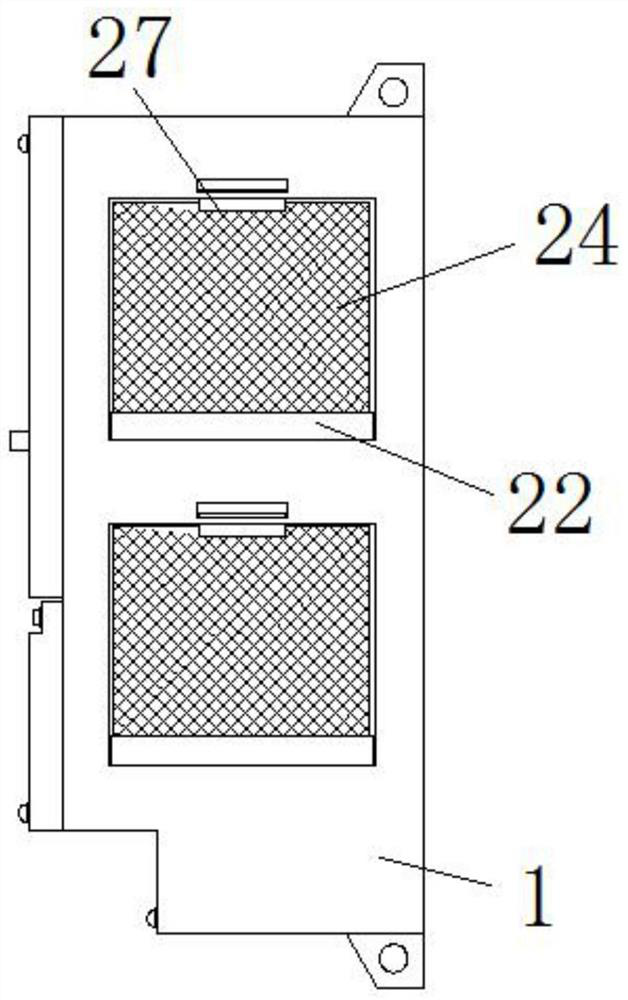

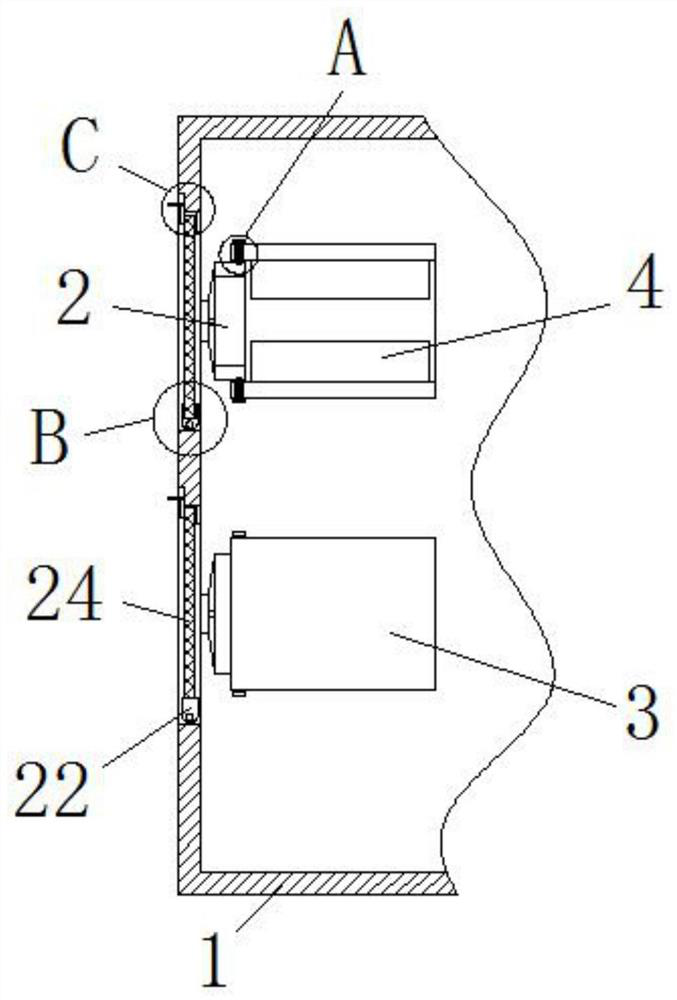

[0030] see Figure 1-6 As shown, the present invention provides a technical solution: a cooling device for a frequency converter of a HVAC compressor, including a housing 1, a cooling fan 2 is fixed on the surface of the inner cavity of the housing 1, and a sleeve is connected to the other end of the cooling fan 2 3. The surface of the inner ring of the sleeve 3 is fixed with a heat sink 4, and one side of the heat sink 4 is provided with a storage tank 5, and the inside of the sleeve 3 is provided with a ring groove 6, and the inside of the ring groove 6 is provided with a ring block 7. The bottom end of the ring block 7 is fixed on the side of the heat sink 4, and the cleaning brush 8 is fixed. The surface of the ring block 7 is fixed on the outside of the sleeve 3. The fixed block 12 is fixed, and the top surface of the ring groove 6 is provided with an arc groove 9. The inner wall surface of the arc groove 9 is engaged with the outer surface of the fixed block 12 to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com