Double-faced mask, cream thereof and preparation method of cream

A cream and facial mask technology, which is applied in the field of skin care products, can solve the problems of difficult adhesion and low absorption of mask materials, and achieve good synergistic effect, good effect and good absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0073] A mask cream comprising the following components:

[0074] Luba Gum, Red Rose Essential Oil, Polyoxyethylene Sorbitan Monostearate, Carbomer, Sodium Acrylate / Sodium Acryloyldimethyltaurate Copolymer, Polysorbate-80, Solvent;

[0075] The solvent is deionized water.

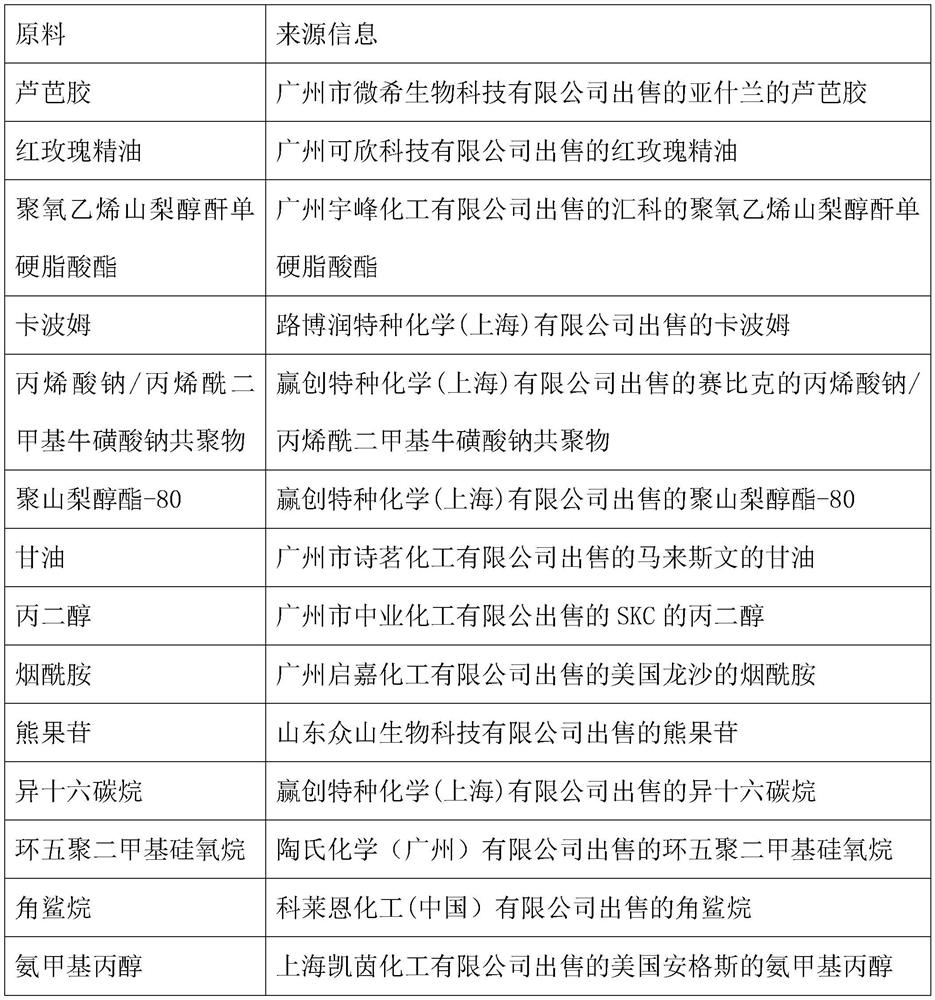

[0076] In embodiment 1-3, the input amount (unit Kg) of each component sees table 2 for details

[0077] Table 2

[0078] Example 1 Example 2 Example 3 Luba Gum 0.9 1.2 1.3 Red Rose Essential Oil 0.01 0.04 0.05 Polyoxyethylene sorbitan monostearate 0.04 0.06 0.08 carbomer 0.3 0.4 0.5 Sodium Acrylate / Sodium Acryloyldimethyltaurate Copolymer 0.6 0.8 0.9 Polysorbate-80 0.2 0.3 0.35 Deionized water 97.99 97.16 96.65

[0079] The preparation method of embodiment 1-3 mask cream comprises the following steps:

[0080] Step 1), raw material pretreatment;

[0081] Step 1-1), adding polyoxyethylene sorbitan monostearate into the stirring t...

Embodiment 4

[0087] A facial mask cream, compared with embodiment 2, the difference only lies in:

[0088] In the preparation method of mask cream:

[0089] In step 1-1), water is heated to 83°C. In step 2), heat to 83°C while stirring, and homogenize for 1 minute.

[0090] In step 2), homogenize for 3 minutes, homogenize for 1 minute, and keep warm at 83°C for 28 minutes. In step 3), the temperature of the third treated object was lowered to 43°C.

Embodiment 5

[0092] A facial mask cream, compared with embodiment 2, the difference only lies in:

[0093] In the preparation method of mask cream:

[0094] In step 1-1), water is heated to 88°C.

[0095] In step 1-2), heat to 88°C while stirring, and homogenize for 1 minute.

[0096] In step 2), homogenize for 8 minutes, homogenize for 4 minutes, and keep warm at 88°C for 32 minutes. In step 3), the temperature of the third treated object was lowered to 47°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com