Lateral propeller with anti-winding function

An anti-winding and thruster technology, which is applied in ship propulsion, propulsion components, ship construction, etc., can solve the problems of increasing thruster resistance, affecting the use of lateral thrusters, and easily entangled in aquatic plants, etc., to achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

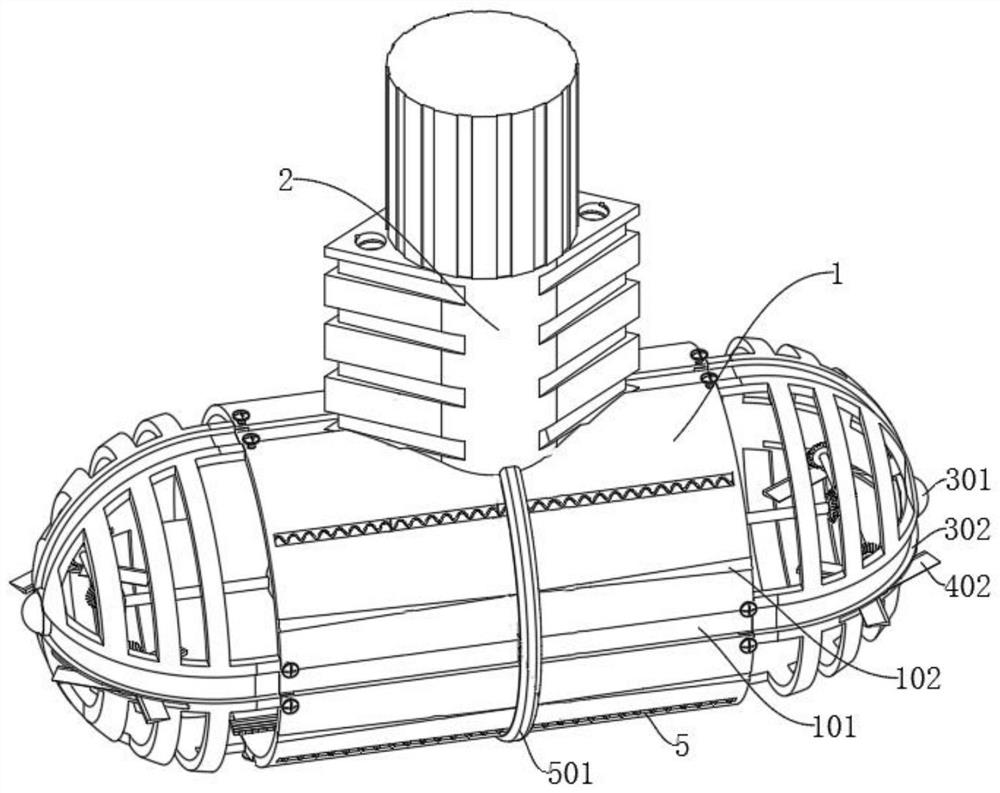

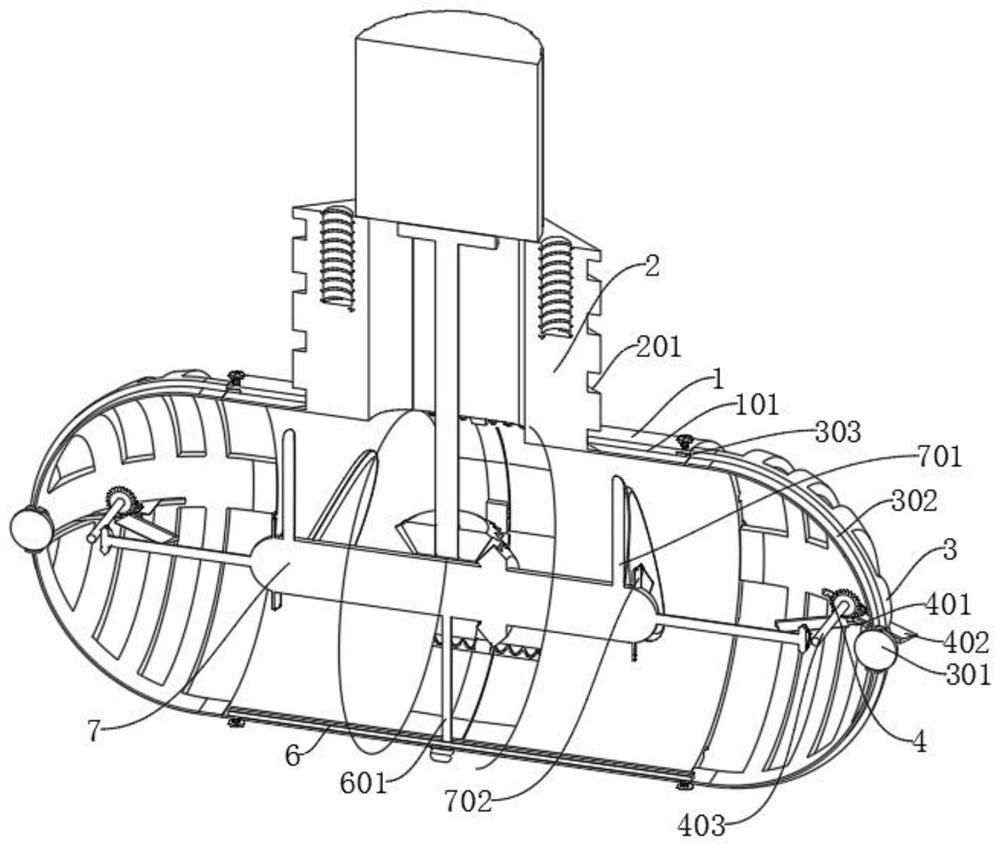

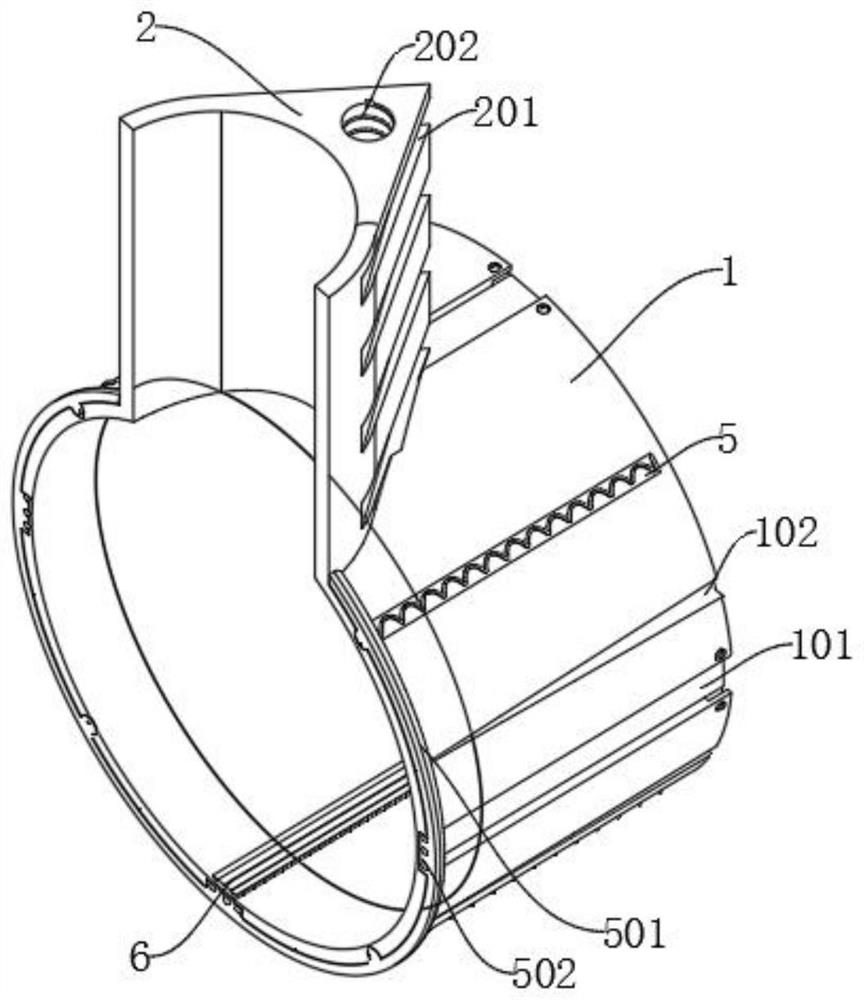

[0030] as attached figure 1 to attach Figure 5 Shown:

[0031]The present invention provides a lateral thruster with anti-winding function, which includes a main body 1, a top plate 2, a filter element 3, a turning groove 4, a chute 5, a scraper 6 and a cross bar 7; the main body 1 is a cylindrical structure, And the side end of the main body 1 is provided with a card slot; the top of the top plate 2 is equipped with a motor, and the top plate 2 is arranged on the top of the main body 1; the side of the filter element 3 is provided with a filter hole, and the clamp plate 303 inside the filter element 3 is threaded The rod is installed inside the card slot at the side end of the main body 1; the turn slot 4 is an arc structure, and the turn slot 4 is arranged on the side of the filter element 3, and the turn bar 403 outside the turn slot 4 passes through the bevel gear and the umbrella at the side end of the cross bar 7 The gears are meshed; the chute 5 is an arc structure, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap