Preparation method of manganous-manganic oxide magnetic wave-absorbing filler

A technology of manganese tetroxide and magnetic wave absorption, which is applied in the fields of manganese oxide/hydroxide, nano-magnetism, and bulk chemical production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

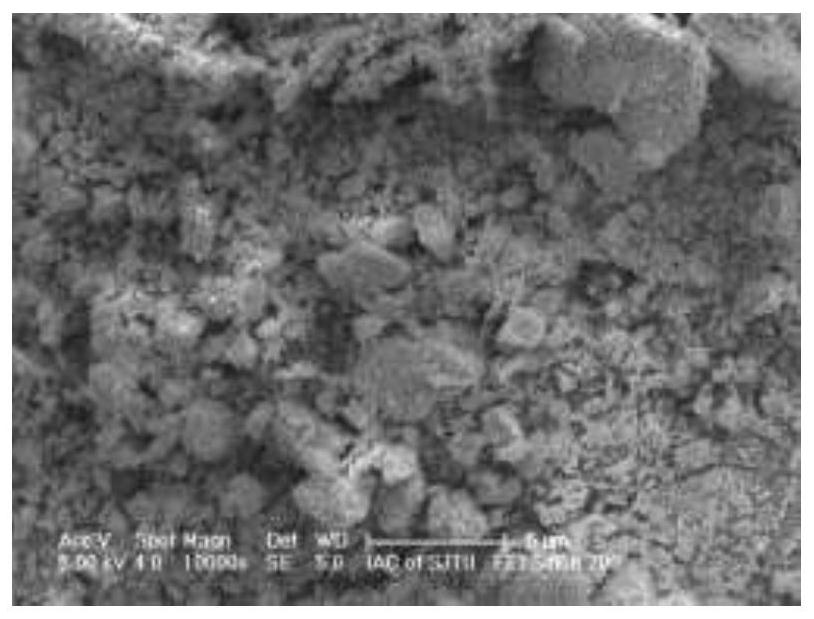

[0036] Take 20mg of pre-prepared H 0.13 MnO 2 0.7H 2 The O nanosheet material was added to a stainless steel reactor, injected with 10ml of DMF solvent, and dispersed ultrasonically for 10 minutes at low power; then the sealed reaction vessel was heated to 673.15K (400°C) in a professionally designed tube furnace, Leave on for 15 minutes. The pressure of the reactor is adjusted by pre-designing the volume of the reaction vessel, the amount of reactants and the temperature. The reaction was finally terminated by rapidly exiting the hot reactor chamber and immersing it in an ice-cold water bath. The supercritical fluid treated product was collected by washing with fresh solvent repeatedly.

Embodiment 2

[0038] Take 19mg of pre-prepared H 0.13 MnO 2 0.7H 2The O nanosheet material was added to a stainless steel reactor, injected with 9ml of DMF solvent, and dispersed ultrasonically for 12 minutes at low power; then the sealed reaction vessel was heated to 673.15K (395°C) in a professionally designed tube furnace, Leave on for 10 minutes. The pressure of the reactor is adjusted by pre-designing the volume of the reaction vessel, the amount of reactants and the temperature. The reaction was finally terminated by rapidly exiting the hot reactor chamber and immersing it in an ice-cold water bath. The supercritical fluid treated product was collected by washing with fresh solvent repeatedly.

Embodiment 3

[0040] Take 18 mg of pre-prepared H 0.13 MnO 2 0.7H 2 The O nanosheet material was added to a stainless steel reactor, injected with 9ml of DMF solvent, and dispersed ultrasonically for 10 minutes at low power; then the sealed reaction vessel was heated to 672.15K (392°C) in a professionally designed tube furnace, Leave on for 8 minutes. The pressure of the reactor is adjusted by pre-designing the volume of the reaction vessel, the amount of reactants and the temperature. The reaction was finally terminated by rapidly exiting the hot reactor chamber and immersing it in an ice-cold water bath. The supercritical fluid treated product was collected by washing with fresh solvent repeatedly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com