Double-station rotary material table

A dual-station, material table technology, applied in the direction of manufacturing tools, furnaces, furnace types, etc., can solve the problems of no translation, inapplicability, and inability to solve the material table, so as to reduce the equipment footprint and increase the function and structure of the material table. Design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

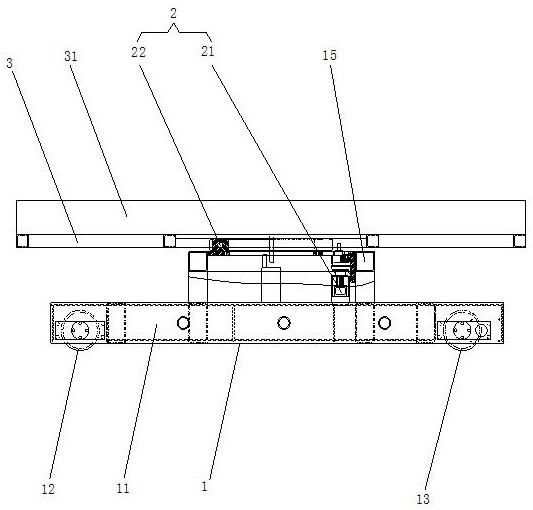

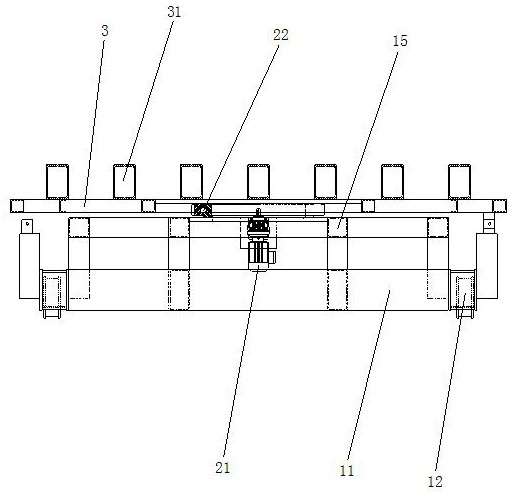

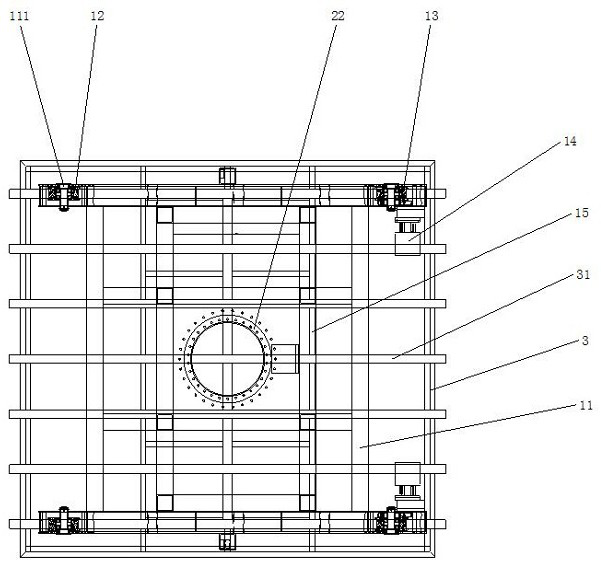

[0017] Attached below figure 1 ~ attached image 3 And specific embodiment, the present invention is described further.

[0018] Such as Figures 1 to 3 As shown, the double-station rotary table of the present invention includes a translational drive system 1 , a rotary drive system 2 and a load-bearing frame 3 .

[0019] The translation drive system 1 includes an underframe 11 , a translation driven roller 12 , a translation driving roller 13 and a translation drive motor 14 . The underframe 11 is a rectangular frame structure and the middle part of the top surface is matched and fixed with a steel frame 15; the bottoms on both sides of the underframe 11 are longitudinally matched with a pair of roller shafts 111; The pair of roller shafts 111 are equipped with translation driven rollers 12 through bearing matching, and the pair of roller shafts 111 located at the bottom of the other lateral side of the chassis 11 are equipped with translation driving rollers 13 through be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com