Low-temperature tapping method for slabs of common carbon structural steel

A kind of carbon structural steel, slab technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

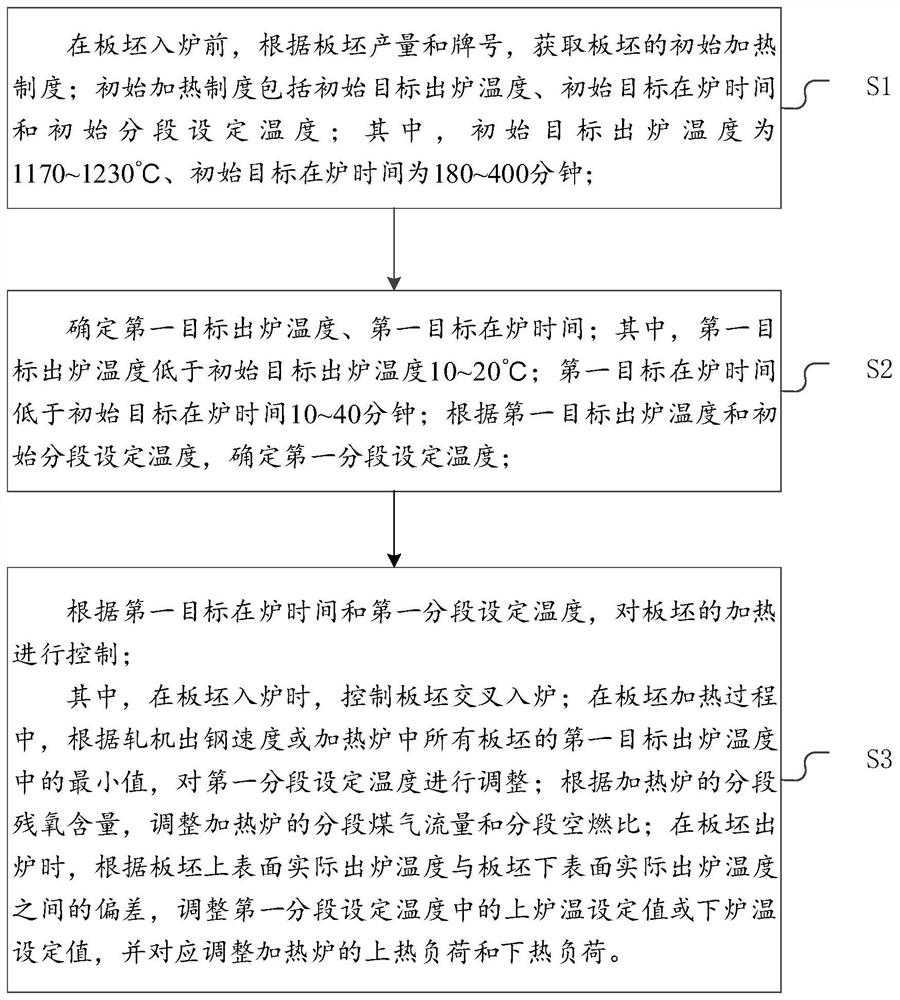

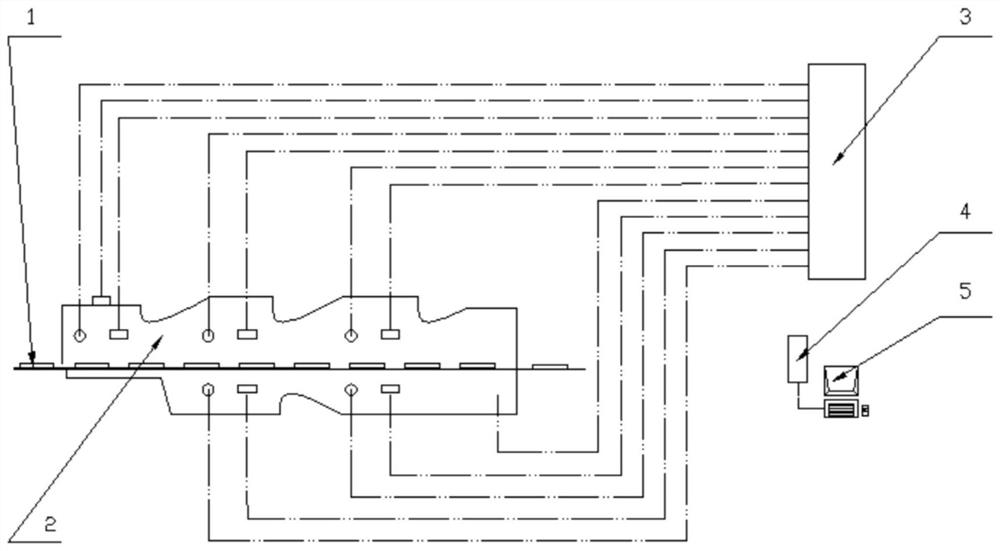

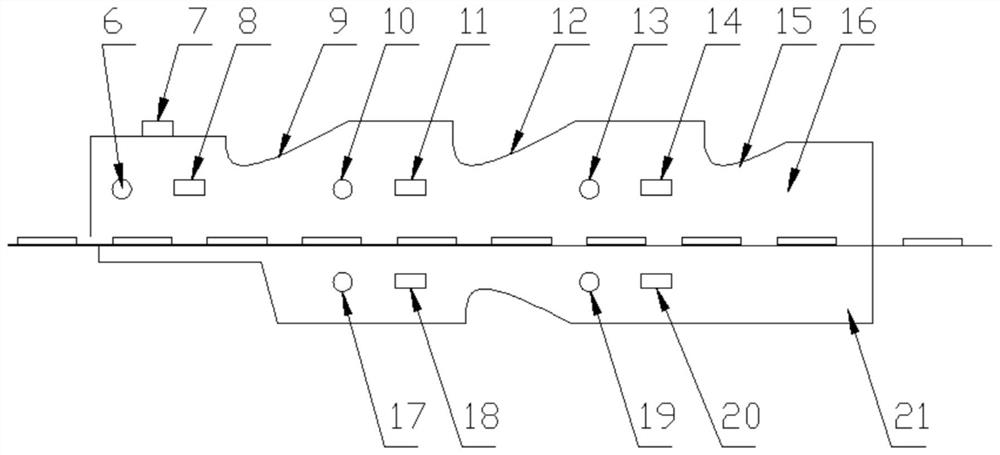

Method used

Image

Examples

Example Embodiment

[0101] Example 1:

[0102] Common carbon steel grade Q345D, the chemical composition of the slab is: C is 0.015%, Si is 0.26%, Mn is 1.43%; the slab size is 2600mm (length) × 1800mm (width) × 300mm (thickness).

[0103] Low temperature tapping is adopted, the target tapping temperature is controlled to be reduced by 10°C on the basis of the initial tapping temperature (1200±30°C), and the target in-furnace time is reduced by 25min on the basis of the initial in-furnace time (300±120min). The corresponding heating system As shown in table 2:

[0104] Table 2: Control of heating parameters for low temperature tapping of slab in Example 1

[0105]

Example Embodiment

[0106] Example 2

[0107] Common carbon steel grade Q345D, the slab belongs to the same furnace steel as Example 1, and its chemical composition is the same: C is 0.015%, Si is 0.26%, and Mn is 1.43%.

[0108] The slab adopts low temperature tapping, and the target tapping temperature is controlled to be reduced by 20°C on the basis of the initial tapping temperature (1200±30°C), and the target in-furnace time is reduced by 40min on the basis of the initial in-furnace time (300±120min). The corresponding The heating system is shown in Table 3:

[0109] Table 3: Heating parameter control for low temperature tapping of slab in Example 2

[0110]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com