Embedded track dynamic vibration absorber

A technology of dynamic vibration absorber and embedded track, which is applied in tracks, roads, buildings, etc., can solve the problems of not considering the influence of vibration suppression of the main system, the design vibration absorption frequency does not match the actual working frequency, and the natural frequency is not considered enough. The vibration reduction performance is efficient and stable, with good elasticity and better vibration reduction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

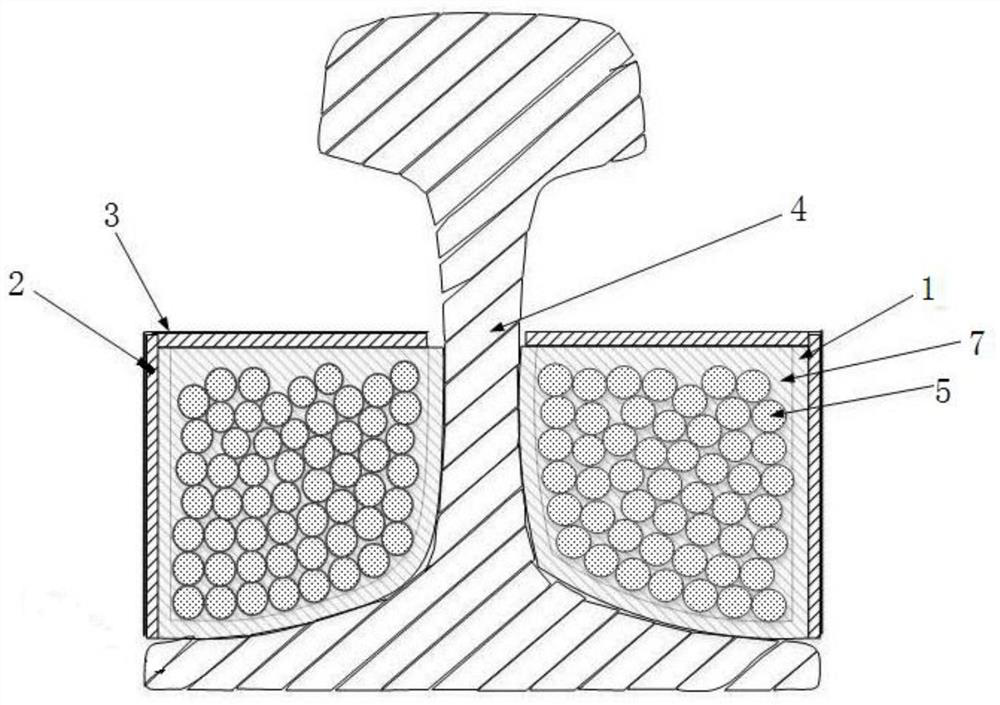

[0040] The invention provides an embedded rail dynamic vibration absorber, such as figure 1 As shown, it includes an elastic unit 1 , a damping unit 2 and a mass unit (steel ball 5 ) arranged on both sides of the rail waist of the rail 4 .

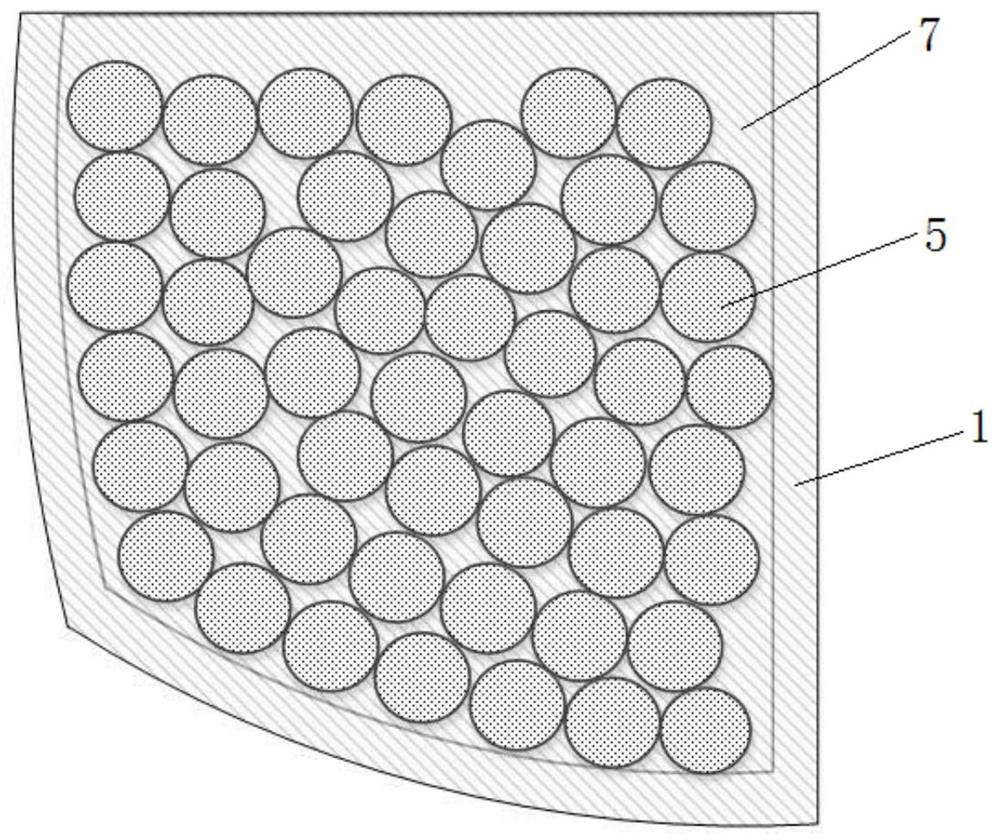

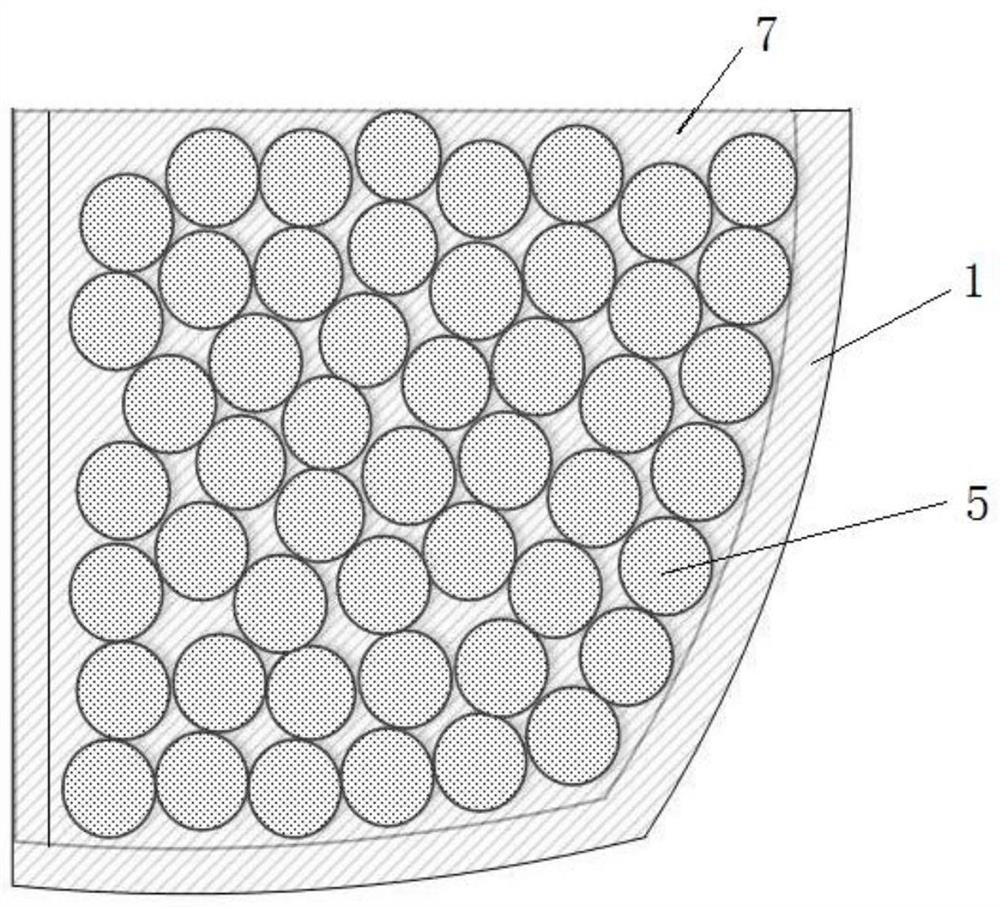

[0041] First make the elastic unit 1, the side and bottom surface of the elastic unit 1 in contact with the rail waist of the rail 4 and the bottom flank of the rail are the same as the surface shape of the rail 4, and the rest of the surface is flat, and the production is formed by hot pressing and vulcanization of the mold. The wall thickness of the elastic unit 1 is 5-20 mm, the material is silicon rubber, and it is empty before the steel ball 5 is filled. The selection of Shore hardness and elastic modulus is related to the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com