A hydraulic pump station skid and a hydraulic pressure-driven pump with a hydraulic pump station skid

A hydraulic pump station and hydraulic technology, which is applied to components, pumps, piston pumps, etc. of elastic fluid pumping devices, can solve the problems of frequent plunger movements, high requirements, narrow coverage, etc., and achieve the maximum displacement of lifting Quantity, the effect of meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

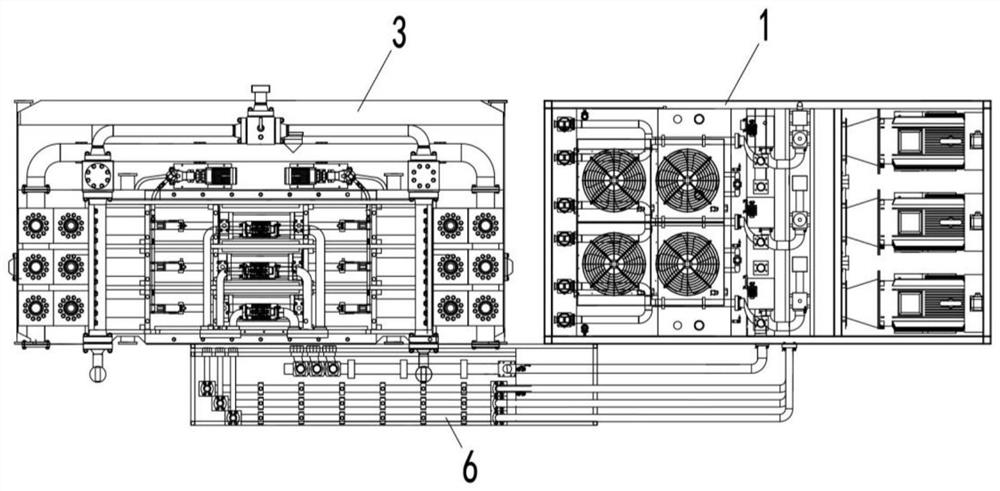

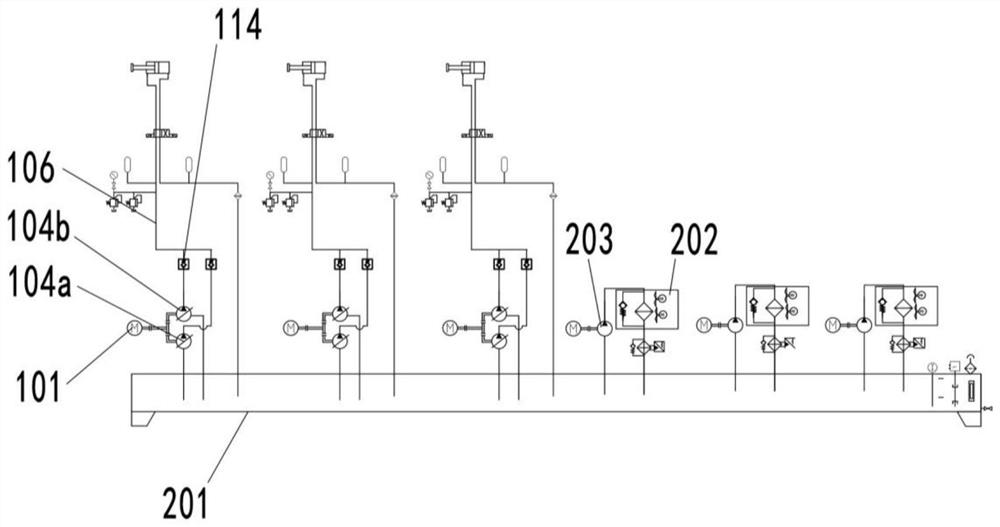

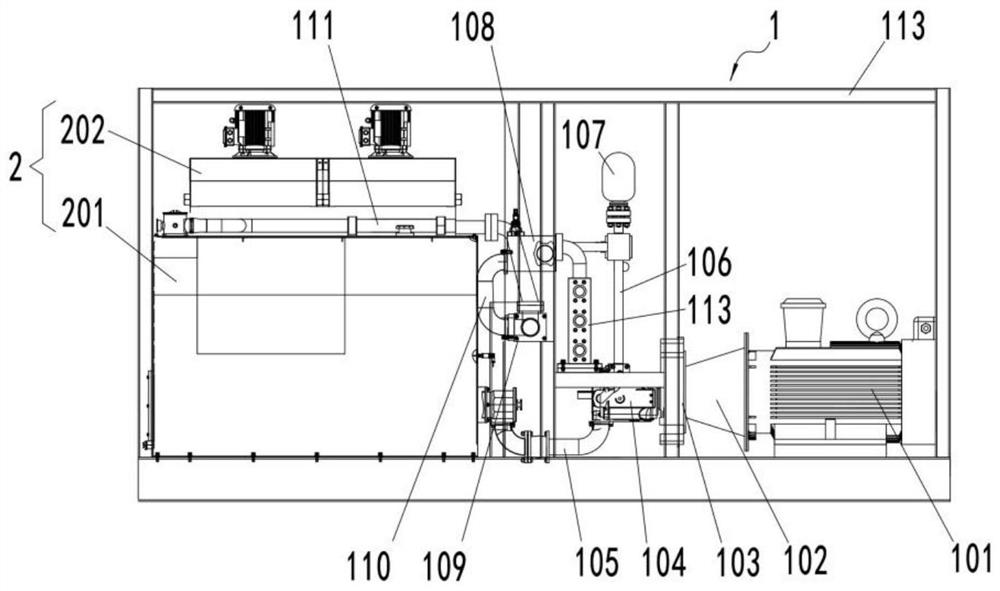

[0073] Such as Figure 1 to Figure 4 As shown, a hydraulic pump station skid 1 includes a plurality of oil supply units, each oil supply unit includes a power element 101, a transfer case 103 and two hydraulic oil pumps 104a, 104b, the power element 101 and the transfer case 103 The input end is connected by transmission, and the transfer case 103 has two output ends, and the output ends of the transfer case 103 are respectively connected by transmission to the hydraulic oil pumps 104a and 104b.

[0074] In the prior art, the displacement of the hydraulic oil pumps 104a and 104b cannot be selected arbitrarily, especially when selecting a hydraulic oil pump with a large displacement, it is often limited by factors such as technical maturity and price. The hydraulic pump station of this embodiment In the skid 1, one power element 101 is used to drive two hydraulic oil pumps 104a, 104b, and the transmission is carried out through the transfer case 103. In the case of using a smal...

Embodiment 2

[0090] Such as Figure 1 to Figure 9 As shown, a hydraulic oil tank, the hydraulic oil tank 2 includes a box body 201, a radiator 202 and a radiator oil pump 203, the suction end of the radiator oil pump 203 is connected to the box body 201, the discharge end of the radiator oil pump 203 is connected to the radiator 202, and the heat dissipation The discharge end of the device 202 is connected with the box body 201. In the traditional hydraulic profile control pump, the radiator 202 is connected to the oil return pipeline 111, while the hydraulic oil tank 2 in this embodiment adopts bypass heat dissipation. On the one hand, the radiator 202 is protected from the impact of the returning hydraulic oil. , it is convenient to match a reasonable heat dissipation oil pump 203 according to heat dissipation requirements, so as to efficiently dissipate heat from hydraulic oil.

[0091] There are multiple radiators 202 and cooling oil pumps 203 , and the radiators 202 correspond to the...

Embodiment 3

[0103] Such as Figure 10 to Figure 13 As shown, a hydraulic pressure-driven pump hydraulic skid 3 includes a frame 301 and three working units connected to the frame 301 . The working unit includes a hydraulic cylinder 302 and a first hydraulic end and a second hydraulic end symmetrically arranged on both sides of the hydraulic cylinder 302 . The hydraulic cylinder 302 includes a hydraulic piston rod 303, the hydraulic piston rod 303 has a first output end and a second output end oppositely arranged, the first output end is connected to the first hydraulic end, and the second output end is connected to the second hydraulic end .

[0104] The frame 301 is installed on the upper side of the base 10, and the base 10 is used to provide support for the frame 301, the slurry suction pipeline system 7, the slurry discharge pipeline system 8 and the spraying system 9.

[0105] In this embodiment, there are three working units, but it should be noted that there may be 2 to 10 workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com