Durable transmission shaft made of composite material

A composite material, transmission shaft technology, applied in the directions of shafts, bearings, shafts and bearings, can solve the problems of inability to meet the requirements of large torque performance, consumption of engine energy, low thermal expansion coefficient, etc., to enhance mechanical properties and reduce energy. Consume and improve the effect of comprehensive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

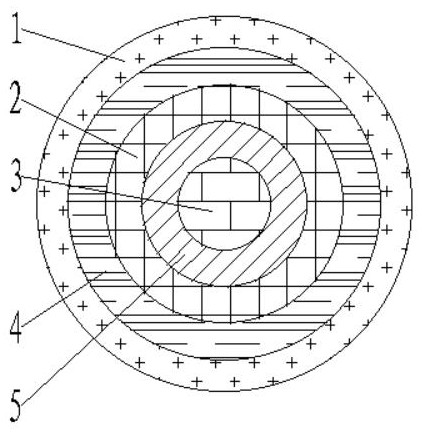

[0026] A durable transmission shaft made of composite materials, comprising: a hybrid fiber surface strength layer 1, a first transition layer 4, a two-dimensional wound fiber hybrid composite torsion layer 2, a second transition layer 5, and a three-dimensional structural rigid layer sequentially arranged from outside to inside 3. The material of the first transition layer 4 is a thermoplastic resin matrix composite material, and the material of the second transition layer 5 is a multi-dimensional hybrid braided composite material.

[0027] The mixed fiber surface strength layer 1 is twill-woven with T300 carbon fiber and K29 aramid fiber at a mixing ratio of 1:1.

[0028] The two-dimensional winding fiber hybrid composite torsion layer 2 is formed by winding T700 carbon fiber and M40 carbon fiber with a mixing ratio of 2:1, and the winding method is 90° hoop winding.

[0029] The three-dimensional structural rigid layer 3 is woven by T800 carbon fiber and M40J carbon fiber...

Embodiment 2

[0036] A durable transmission shaft made of composite materials, comprising: a hybrid fiber surface strength layer 1, a first transition layer 4, a two-dimensional wound fiber hybrid composite torsion layer 2, a second transition layer 5, and a three-dimensional structural rigid layer sequentially arranged from outside to inside 3. The material of the first transition layer 4 is a thermoplastic resin matrix composite material, and the material of the second transition layer 5 is a multi-dimensional hybrid braided composite material.

[0037] The mixed fiber surface strength layer 1 is made of T800 carbon fiber and K49 aramid fiber plain weave with a mixing ratio of 2:1.

[0038] The two-dimensional winding fiber hybrid composite torsion layer 2 is formed by winding T300 carbon fiber and M55 carbon fiber with a mixing ratio of 1:1, and the winding method is 20° longitudinal winding.

[0039] The three-dimensional structural rigid layer 3 is woven by T1000 carbon fiber and M60J ...

Embodiment 3

[0046] A durable transmission shaft made of composite materials, comprising: a hybrid fiber surface strength layer 1, a first transition layer 4, a two-dimensional wound fiber hybrid composite torsion layer 2, a second transition layer 5, and a three-dimensional structural rigid layer sequentially arranged from outside to inside 3. The material of the first transition layer 4 is a thermoplastic resin matrix composite material, and the material of the second transition layer 5 is a multi-dimensional hybrid braided composite material.

[0047]The mixed fiber surface strength layer 1 is made of satin weaving of T1000 carbon fiber and K129 aramid fiber with a mixing ratio of 2:3.

[0048] The two-dimensional winding fiber hybrid composite torsion layer 2 is formed by winding T300 carbon fiber and M55 carbon fiber with a mixing ratio of 1:1, and the winding method is 85° hoop winding.

[0049] The three-dimensional structural rigid layer 3 is woven by T1000 carbon fiber and M60 car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com