Coal-fired boiler pneumatic soot blowing system with circular lower spray pipe type nozzle and soot blowing method

A technology of soot blowing system and coal-fired boiler, which is applied to the field of soot blowing system with circular down-spout nozzle and soot blowing in the pneumatic soot blowing system of coal-fired boiler, can solve the problem of single structure, dead angle of soot blowing area, limited soot blowing effect, etc. To solve the problem of ash accumulation, enhance disturbance, and improve the effect of soot blowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0026] Example.

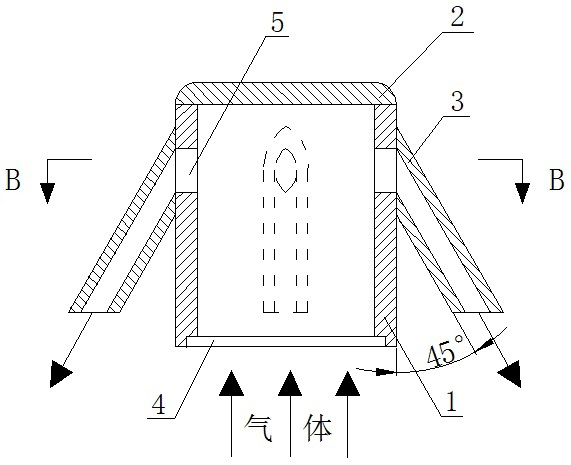

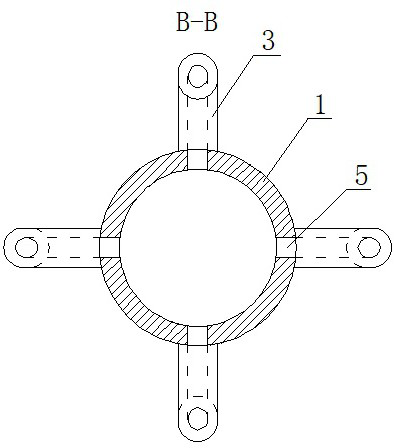

[0027] see Figure 1 to Figure 2 , in this embodiment, a coal-fired boiler pneumatic soot blowing system with a circular lower nozzle nozzle, including a cylindrical air chamber 1, the air chamber head 2 and a lower nozzle 3, one end of the cylindrical air chamber 1 is set There is a sunken interface 4 for connecting compressed air or steam medium pipelines. The other end of the cylindrical air chamber 1 is welded to the air chamber head 2. The upper part of the cylindrical air chamber 1 is provided with several air ports 5 along the circumference. Nozzle 3 is welded on the outer wall of cylindrical air chamber 1 at the position of gas port 5 .

[0028] In this embodiment, four air ports 5 are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com