Sandy riverbed sediment pore water collecting device and manufacturing method thereof

A technology for collecting devices and sediments, which is applied to measuring devices, sampling devices, sampling, etc., can solve the problems of large external disturbance, low success rate, high cost, etc., and achieves strong operability, stable material structure, and improved sampling accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

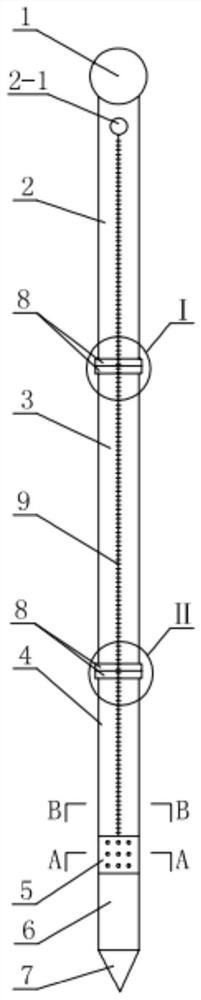

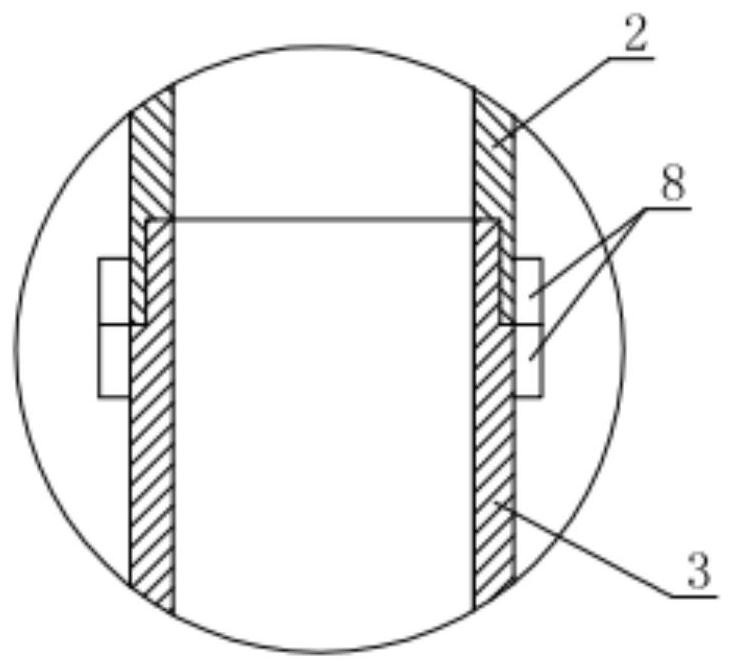

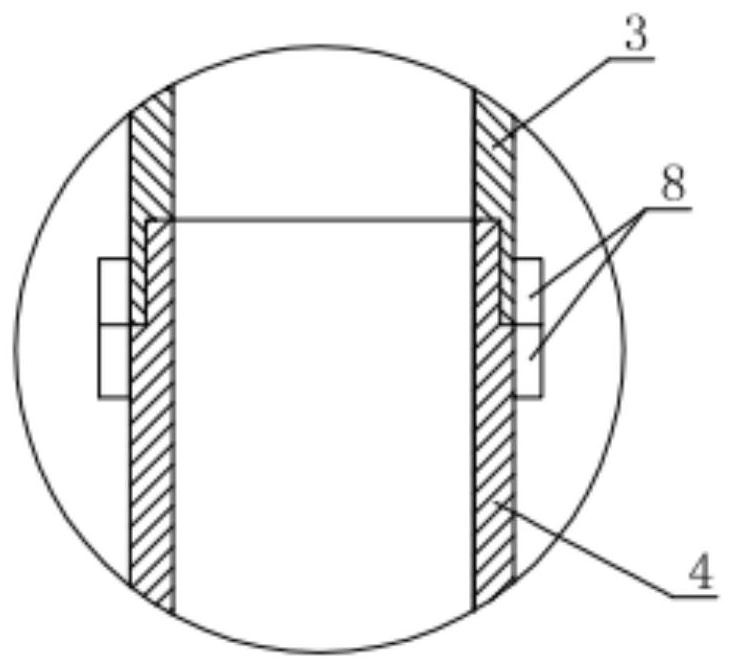

[0033] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes solid force bearing steel ball 1, upper steel pipe 2, middle steel pipe 3, lower steel pipe 4, water inlet section 5, bottom steel pipe 6 and conical drill bit 7, upper steel pipe 2, middle steel pipe 3, lower The steel pipe 4, the water inlet section 5, and the bottom steel pipe 6 are arranged sequentially from top to bottom. The solid stressed steel ball 1 is arranged on the top of the upper steel pipe 2. The conical drill 7 is arranged on the lower end of the bottom steel pipe 6. On the pipe wall of the upper steel pipe 2 Two sampling holes 2-1 are arranged symmetrically with respect to the axis. The diameter of the sampling hole 2-1 is 2.5cm. The inner diameters of the upper steel pipe 2, the middle steel pipe 3 and the lower steel pipe 4 should all be greater than 2.5cm, and 2.5cm can be used for water sample collection. The pump head reaches the water...

specific Embodiment approach 2

[0037] Specific implementation mode two: combination Figure 1 to Figure 6 Describe this implementation mode, this implementation mode is realized through the following steps:

[0038] Step 1. Preparation of device materials:

[0039] (1) Preparation of solid stressed steel ball 1: select a stainless steel ball with a diameter of 8 cm as the solid stressed steel ball 1;

[0040](2) Prepare the upper steel pipe 2: select a stainless steel pipe with a length of 100 cm and an outer diameter of 5 cm as the upper steel pipe 2, set an internal thread at the inner diameter of the lower end of the upper steel pipe 2, and weld a hexagonal sleeve 8 at the outer diameter. There are two sampling holes 2-1 symmetrical to the axis on the pipe wall, the diameter of which is 2.5cm, and the pump head of the water supply sample collection pump and the sampling pipe are inserted into the water surface of the steel pipe;

[0041] (3) Prepare the middle steel pipe 3: select a stainless steel pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com