Microfluid dielectrophoresis separation device and manufacturing method of microfluid dielectrophoresis separation device

A separation device, dielectrophoresis technology, which is applied in measurement devices, individual particle analysis, material analysis by electromagnetic means, etc. The effect of matching difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

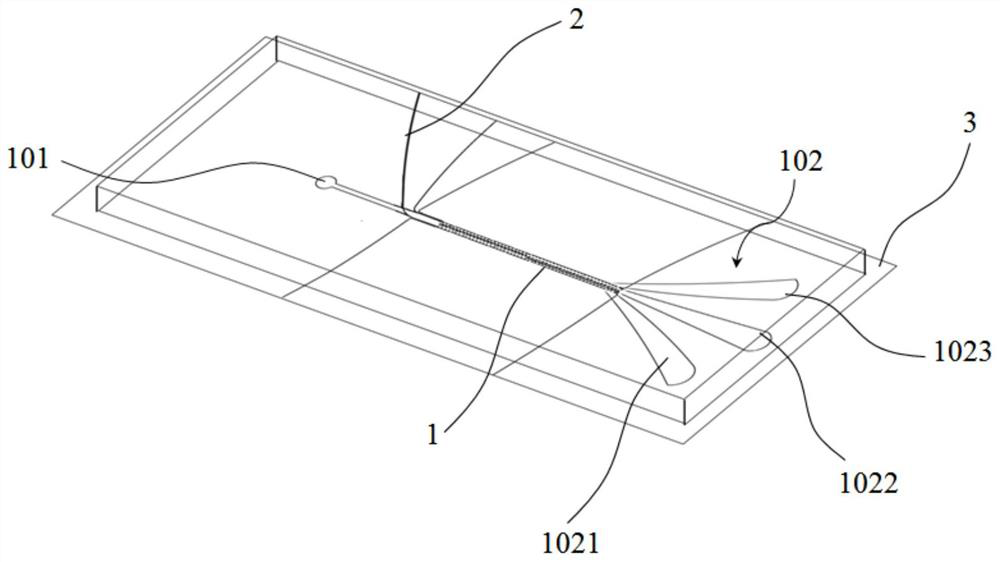

[0079] Figure 5 A schematic diagram of the separation of yeast cells and PS particles using the microfluidic dielectrophoresis separation device of the embodiment of the present invention is shown. In this embodiment, red polystyrene microspheres (PS particles) with a particle size of 7 microns are used to mix with yeast cells , to test the separation effect of the microfluidic dielectrophoretic separation device.

[0080] Firstly, the particle mixture is passed into the microfluidic channel 1 from the inlet 101 . Therefore, the mixed particles do not need to undergo pre-agglomeration operations. The conductivity of the particle mixture is preferably in the range of 10-100ms / cm. When separating yeast and PS particles, a 20Vpp, 500kHz sinusoidal signal is used to generate an electric field. like Figure 5 As shown, yeast cells are subjected to a positive dielectrophoretic force (pDEP) and move towards the high-field region at the tip of the electrode. The curved structure ...

Embodiment 2

[0083] Figure 6(a) and Figure 6(b) show a schematic diagram of the separation of red blood cells and tumor cells using the microfluidic dielectrophoretic separation device of the embodiment of the present invention, and the left figure of Figure 6(a) shows red blood cells It is a schematic diagram of the state of the tumor cells just entering the microfluidic channel 1 , and the right figure of FIG. In the second embodiment, the same parameters of the microfluidic dielectrophoretic separation device as in the first embodiment are used to verify the feasibility of the microfluidic dielectrophoretic separation device for separating biological cells.

[0084] The tumor cells may be breast cancer cells (MDA-MB-231), and 17Vpp, 75kHz sinusoidal signals are used to generate an electric field for separating erythrocytes and breast cancer cells. The mixed liquid of red blood cells and breast cancer cells is passed into the microfluidic channel 1 from the inlet 101, and after being pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com