Converter tapping silicon-manganese alloy addition amount determination method based on yield prediction

A silicon-manganese alloy and determination method technology, applied in the field of iron and steel metallurgy, can solve problems such as difficulty in obtaining a prediction effect model, poor generalization effect, inability to consider the metallurgical mechanism of alloying reaction, etc., so as to improve the generalization ability and improve the economy benefit, the effect of improving the forecast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

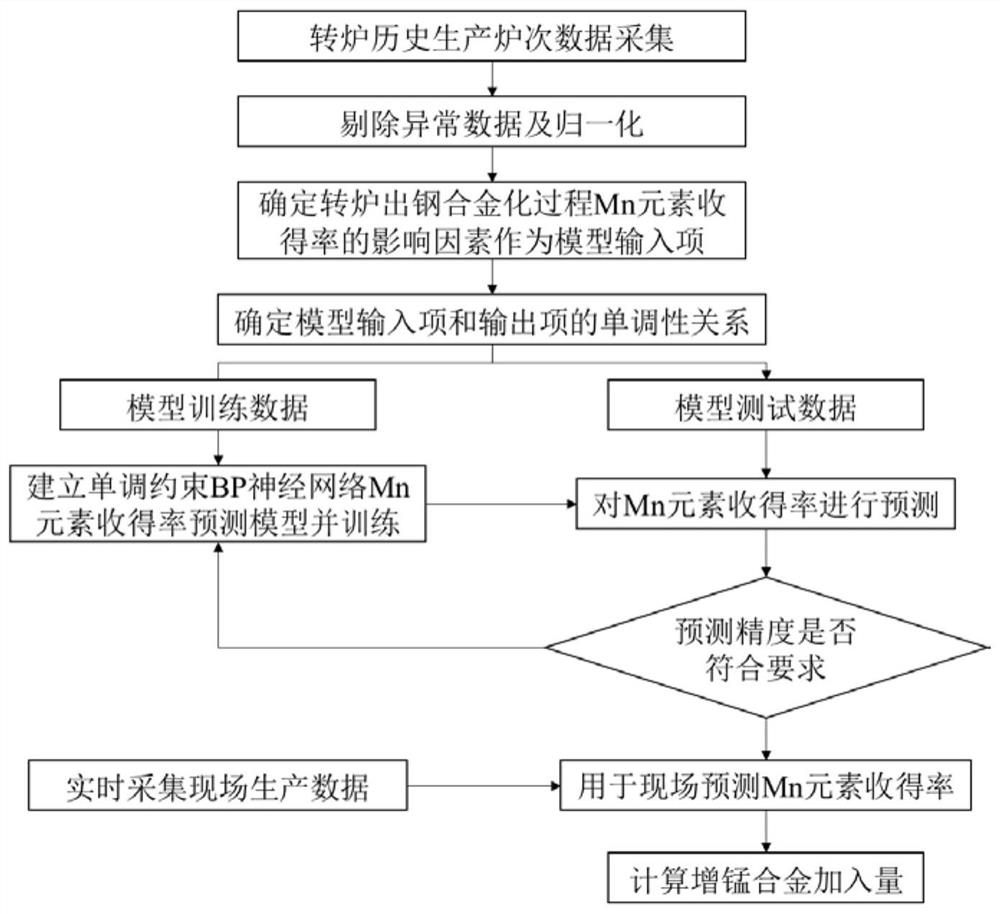

Method used

Image

Examples

Embodiment 1

[0055] A steelmaking plant produces HRB400 series steel grades. During the tapping process, silicon-manganese alloys need to be added to the molten steel to increase manganese, so as to meet the requirements of the Mn element content of the finished steel. In actual production, the amount of silicon-manganese alloy added is estimated by the operator based on experience, which often leads to waste or multiple additions of silicon-manganese alloy. In order to solve this problem, the method of the present invention is used to establish a prediction model for the yield of Mn element, and based on this, the addition amount of the silicon-manganese alloy is calculated.

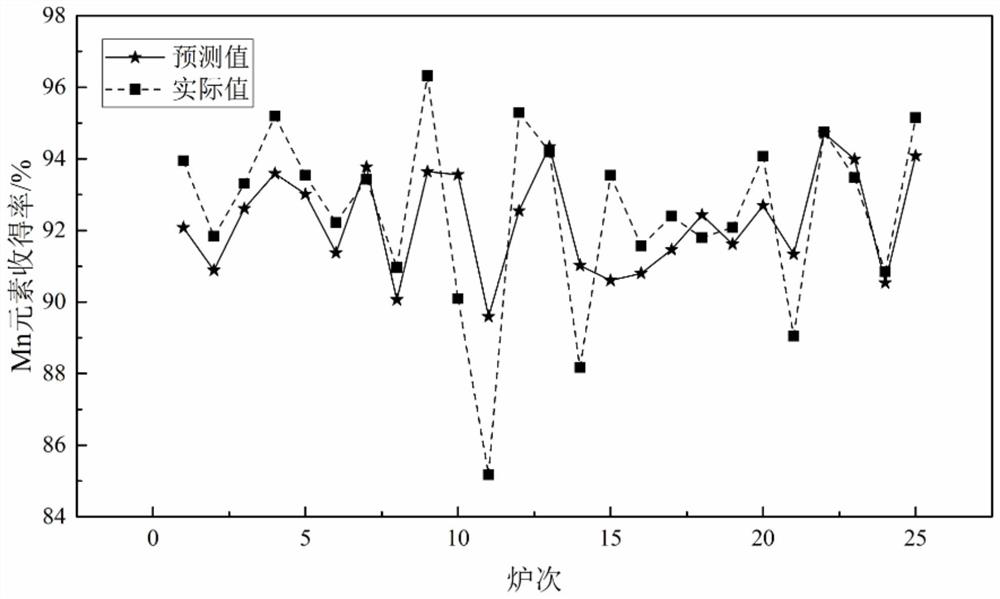

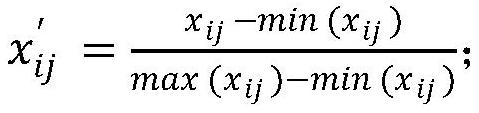

[0056] The production data of a 120t converter in the plant were collected, and the furnaces whose values fell outside the reasonable range were eliminated, and 483 sets of valid data were obtained. In order to eliminate the adverse impact of different variables on the model due to different magnitudes, the data i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com