Large-current high-breaking fuse

A high breaking and fuse technology, used in circuits, electrical components, emergency protection devices, etc., can solve problems such as easy explosion and fuse structural defects, achieve high thermal conductivity and insulation performance, and facilitate the absorption of arc energy and energy. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

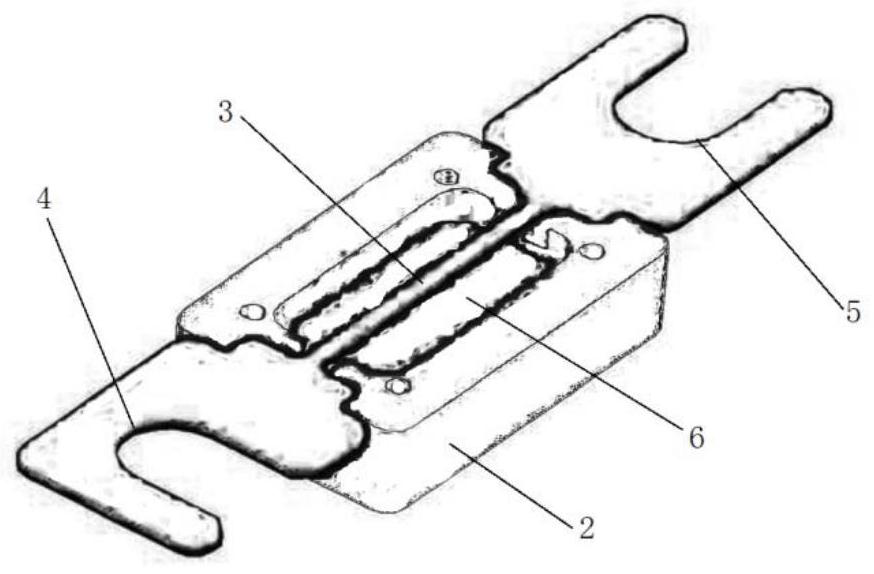

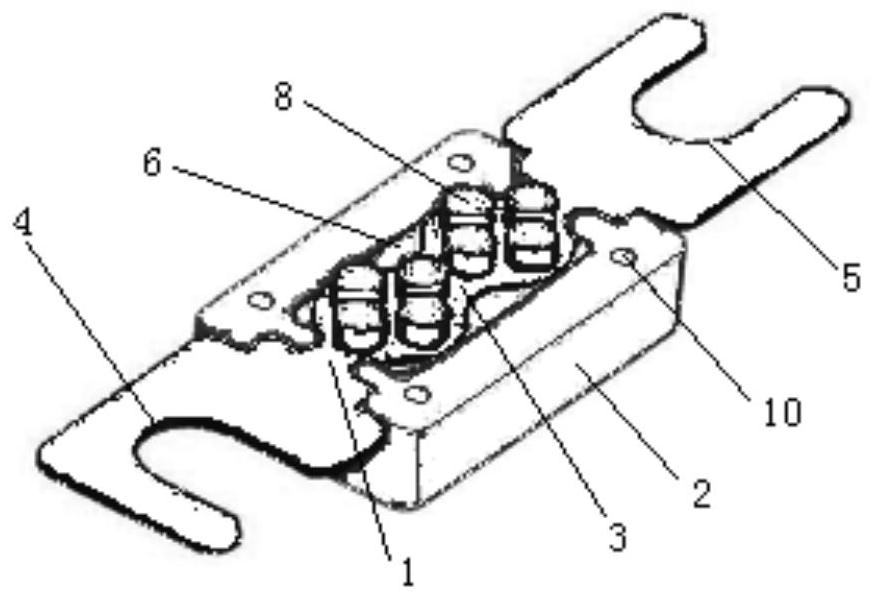

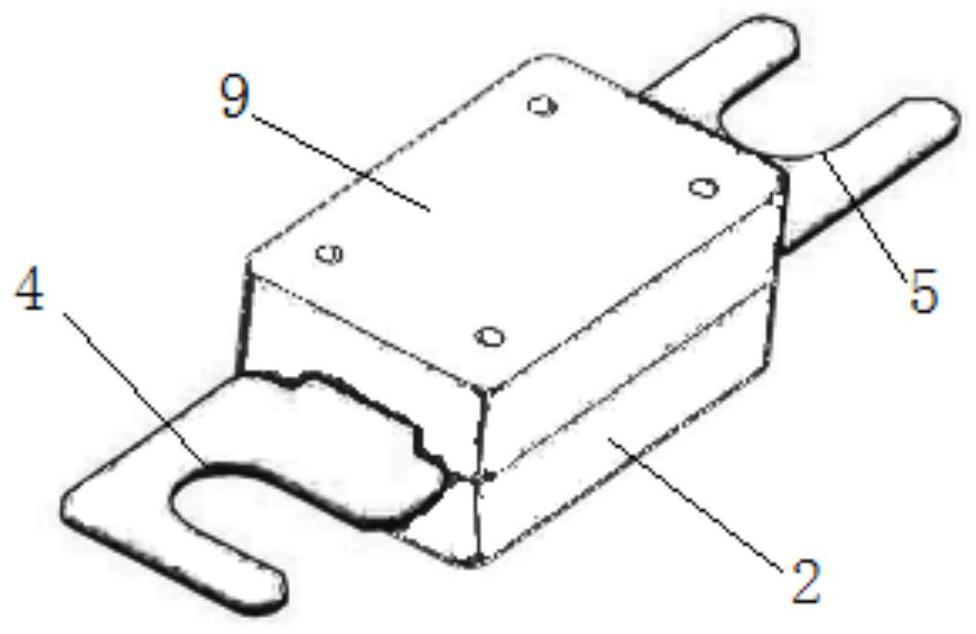

[0032]A high-current high-breaking fuse, including a fuse body and a ceramic seat, the fuse body includes a fuse part, a left installation part connected to the left side of the fuse part, and a right installation part connected to the right side of the fuse part, the fuse part Arranged in the ceramic seat, the gap between the fuse part and the ceramic seat is filled with an arc extinguishing medium, the fuse part is a peanut-shaped structure, and a number of through holes are opened on the fuse part, and the ceramic seat is located in the through hole A high-voltage arc-extinguishing silicone rubber column is fixed inside, and a ceramic fixed cover is installed on the ceramic seat.

[0033] Through this arrangement, the fusing part has a peanut-shaped structure, and several through holes are opened on the fusing part, thereby forming a porous, multi-breakpoint, peanut-shaped fusing structure. In the case of the same cross-sectional area as that of a single linear fuse, the cr...

Embodiment 2

[0035] On the basis of Example 1, the material of the arc extinguishing medium is quartz sand.

Embodiment 3

[0037] On the basis of Embodiment 1, a number of threaded holes are opened on the ceramic seat, and a number of mounting holes are correspondingly opened on the ceramic fixing cover, and screws matching the threaded holes are installed in the mounting holes, and the ceramic fixing cover The cover is threadedly connected with the ceramic seat by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com