Food processing device

A food processing device and component technology, applied in the field of food processing, can solve the problems of poor adjustment ability and pressing effect, low cleaning efficiency, water consumption, etc., and achieve the effect of convenient operation, good cleaning effect and convenient circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

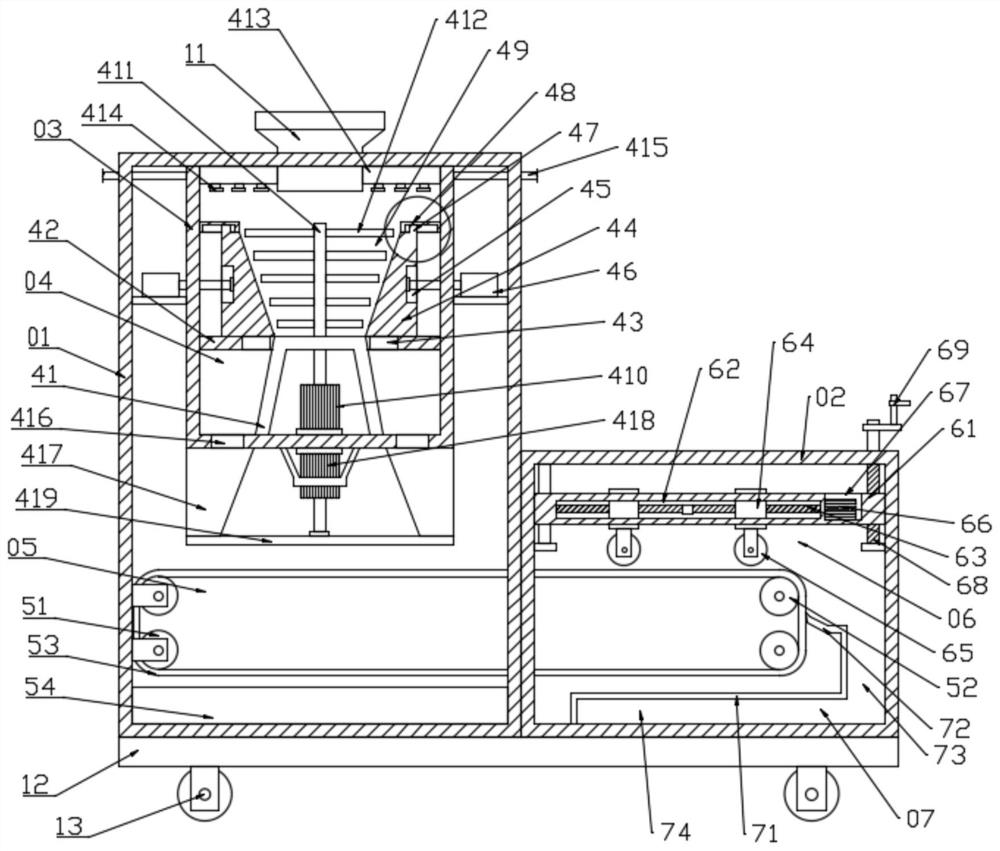

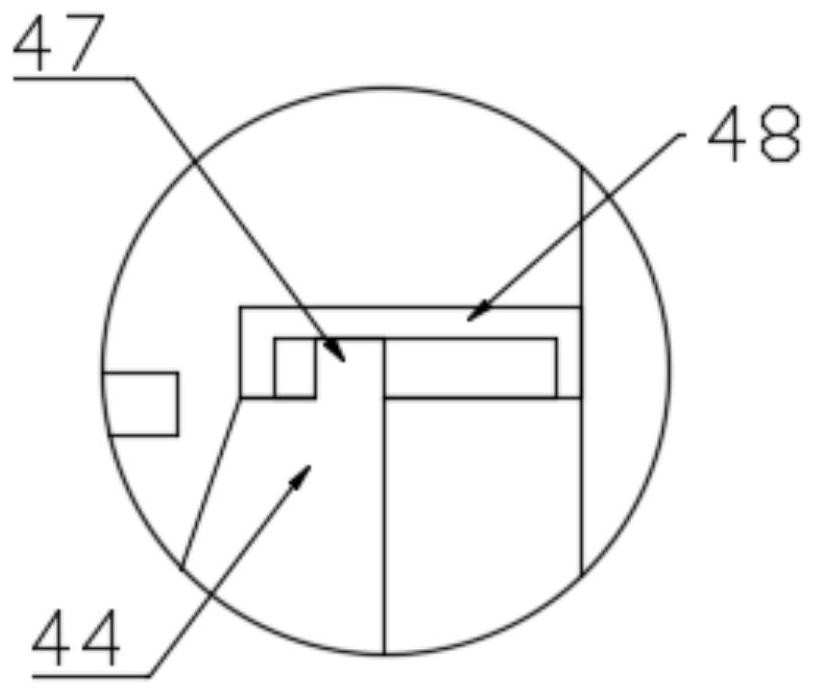

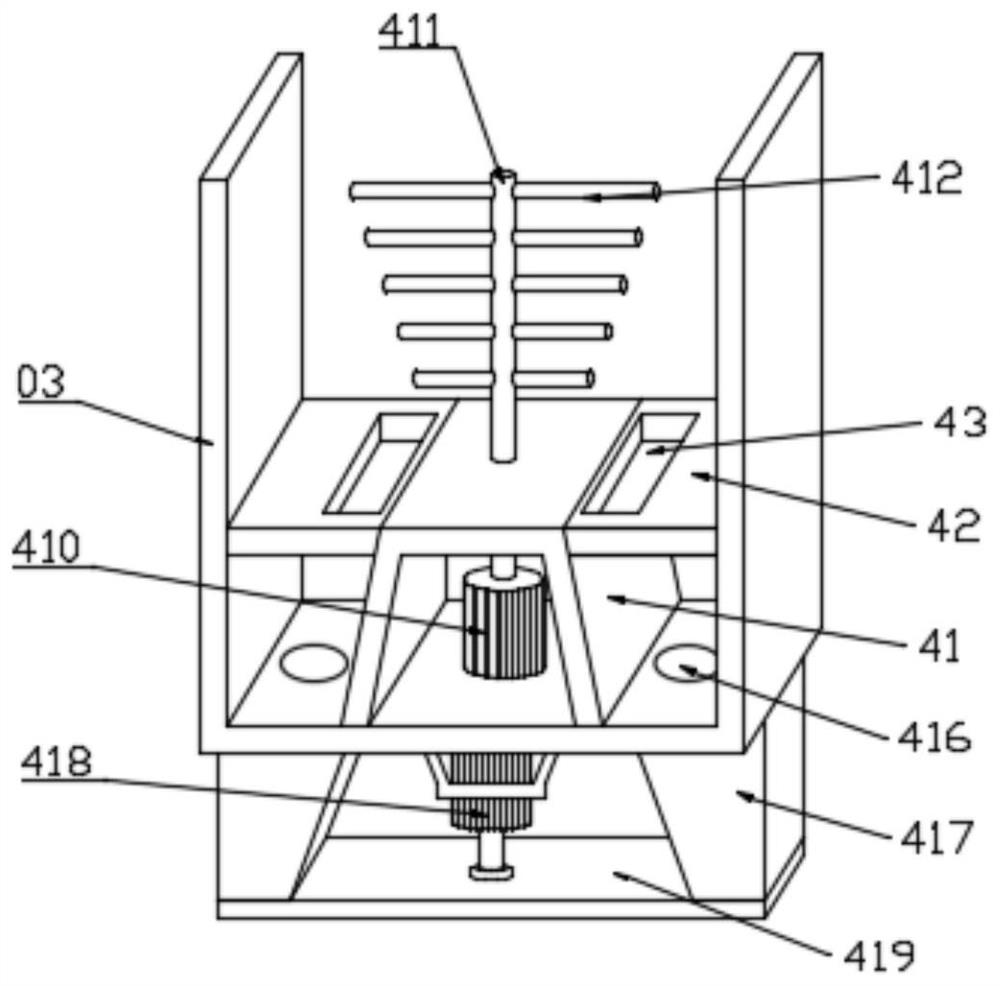

[0028] see Figure 1~4 , in an embodiment of the present invention, a food processing device includes a processing box 01, the processing box 01 is provided with a feed port 11, through the feed port 11, it is convenient for raw materials to enter the processing box 01 for cleaning, and the feed port 11 and The cleaning box 03 in the processing box 01 is connected, and the cleaning box 03 is equipped with a cleaning component 04, which plays a very good cleaning effect on the raw materials through the cleaning component 04, which is very simple and practical; one side of the processing box 01 is fixed with a pressing box 02, a pressing assembly 06 is installed in the pressing box 02, and the raw materials for food processing can be pressed through the pressing assembly 06, which is very simple; in addition, the processing box 01 and the pressing box 02 are also provided with a transfer assembly 05, through which The transfer assembly 05 can transfer the cleaned raw materials t...

Embodiment 2

[0040] see Figure 5-6 , the conveying chamber 73 is provided with a drying assembly 08 through which the raw material can be dried; the drying assembly 08 includes a drying box 81 fixed in the conveying chamber 73 for drying The box 81 is fixed with staggered inclined baffles 82, which improves the residence time of the raw materials; the drying box 81 is inserted with an air inlet pipe 83, and the air inlet pipe 83 communicates with the hot air blower 84, so that the hot air can be transferred to the oven. In the drying box 81, it is convenient to dry the raw materials.

[0041] The working principle of the present invention is: the raw material enters the cleaning chamber 49 through the feeding port 11, and the raw material is cleaned by the stirring component and the water adding component. The first through hole 43 and the second through hole 416 enter in the discharge port 417, and then the second motor 418 works to drive the baffle plate 419 to rotate, the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com