Energy-storage luminescent coating, reflective fabric and preparation process

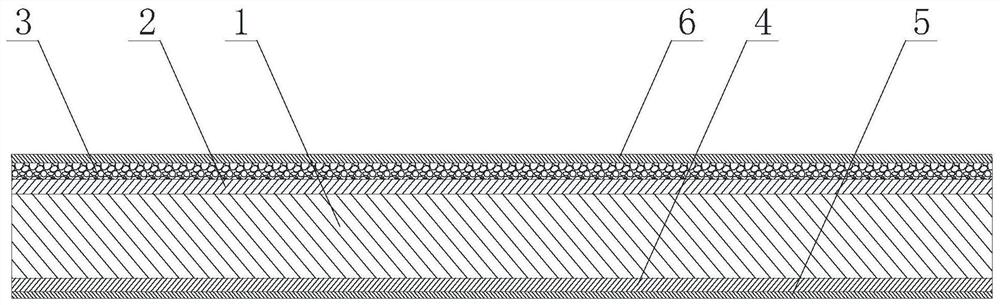

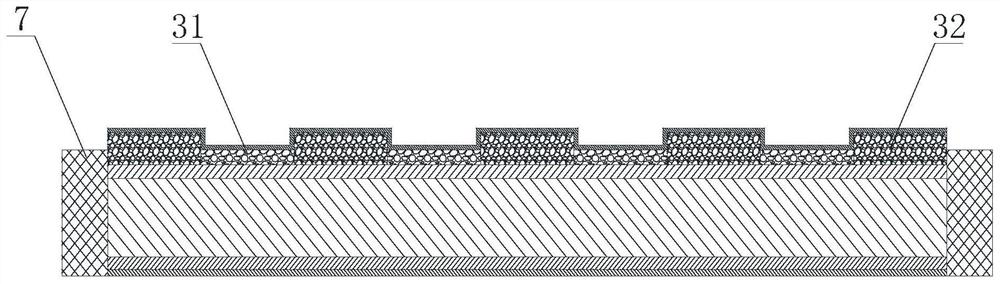

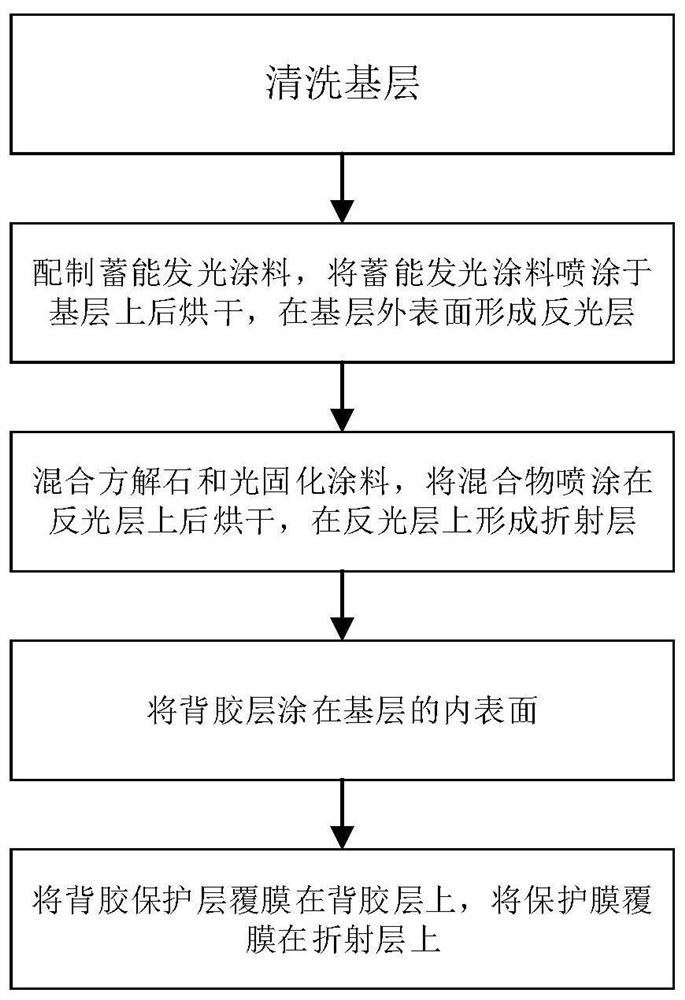

A technology of energy-storing luminous and reflective cloth, which is applied in the field of tunnel light environment, can solve the problems of poor thermal insulation effect of glass beads, easy failure, paint peeling off, etc., to achieve improved diffuse reflection effect, good heat preservation effect, and avoid unevenness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Mix the following raw materials according to mass percentage: 40% inorganic adhesive, 5% reflective powder, 2% red phosphor, 2% green phosphor, 2% blue phosphor, 0.02% fluorescent whitening agent, 0.1% brightener, yellowing agent 0.01% transparent agent, 0.1% UV absorber, 0.5% dispersant, 0.2% defoamer, TiO 2 Powder 10%, water 38.07%. After mixing, use a high-speed stirrer to stir for 5 minutes to obtain the nano energy storage luminescent coating P1. Among them, TiO 2 The particle size of the powder is 80nm, and the fluorescent whitening agent adopts stilbene.

Embodiment 2

[0070] Mix the following raw materials according to mass percentage: inorganic adhesive 45%, reflective powder 6%, red phosphor 2.5%, green phosphor 2.5%, blue phosphor 2.5%, fluorescent whitening agent 0.05%, brightener 0.1%, yellowing 0.02% clearing agent, 0.2% UV absorber, 0.8% dispersant, 0.3% defoamer, TiO 2 Powder 12%, water 28.03%. After mixing, use a high-speed stirrer to stir for 8 minutes to obtain the nano energy storage luminescent coating P2. Among them, TiO 2 The particle size of the powder is 90nm, and the fluorescent whitening agent adopts stilbene.

Embodiment 3

[0072] Mix the following raw materials according to mass percentage: inorganic adhesive 48%, reflective powder 8%, red phosphor 3%, green phosphor 3%, blue phosphor 3%, fluorescent whitening agent 0.1%, brightener 0.3%, yellowing agent 0.05% transparent agent, 0.4% UV absorber, 1.2% dispersant, 0.5% defoamer, TiO 2 Powder 15%, water 17.45%. After mixing, use a high-speed stirrer to stir for 12 minutes to obtain the nano energy storage luminescent coating P3. Among them, TiO 2 The particle size of the powder is 100nm, and the fluorescent whitening agent adopts stilbene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com